Comparing G10 and FR4 for Electrical Insulation Applications

2025-08-14 17:13:05

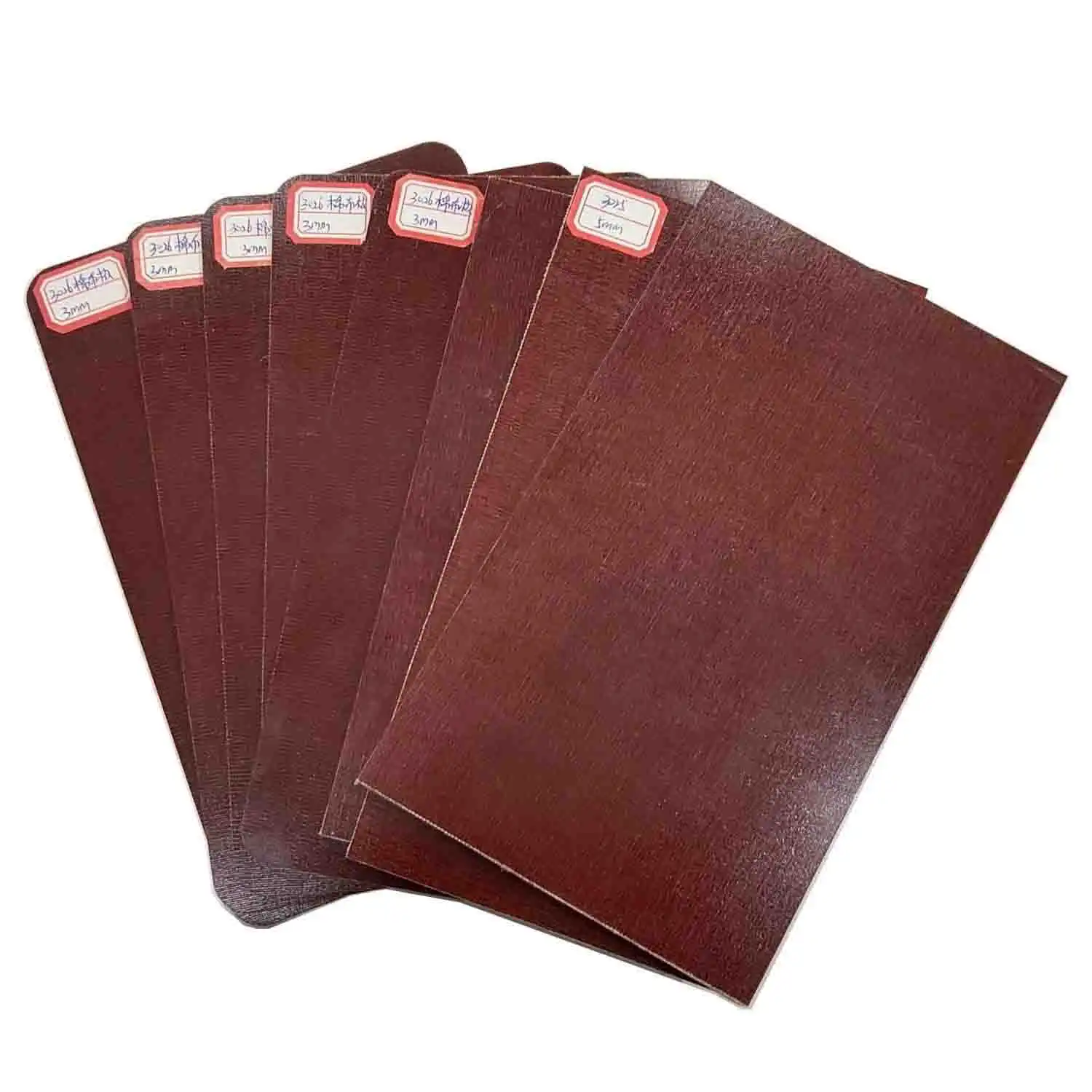

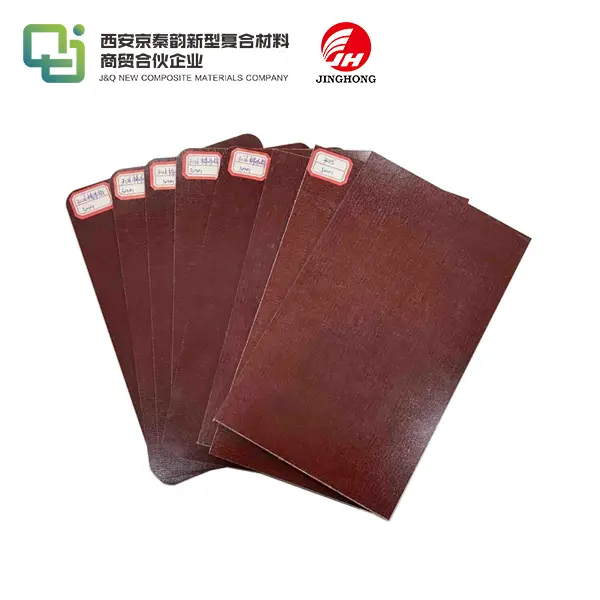

When it comes to electrical insulation applications, G10 sheet and FR4 are two materials that often come up in discussions. Both are glass-reinforced epoxy laminates with excellent electrical and mechanical properties, making them popular choices in various industries. However, they have distinct characteristics that set them apart. G10 is known for its high mechanical strength and chemical resistance, while FR4 boasts superior flame-retardant properties. This article delves into the nuances of these materials, exploring their similarities, differences, and optimal applications to help you make informed decisions for your electrical insulation needs.

What Are the Key Differences Between G10 and FR4 in Electrical Use?

Composition and Manufacturing Process

G10 and FR4 sheets share a similar base composition of woven glass fabric impregnated with epoxy resin. However, the manufacturing process and specific additives used create notable differences. G10 is typically cured at higher temperatures and pressures, resulting in a denser, more rigid material. FR4, on the other hand, incorporates additional flame-retardant chemicals during production, enhancing its fire-resistant properties.

Flame Retardancy

The most significant difference between G10 and FR4 lies in their flame-retardant capabilities. FR4, as its name suggests (FR stands for Flame Retardant), is specifically designed to resist combustion and slow down flame spread. It meets UL94 V-0 standards, making it an excellent choice for applications where fire safety is paramount. G10, while still offering some flame resistance, does not match FR4's level of fire protection.

Electrical Properties

Both G10 and FR4 sheets exhibit excellent electrical insulation properties, but there are subtle differences. G10 typically has a slightly higher dielectric strength, meaning it can withstand higher voltages before breakdown occurs. FR4, however, often demonstrates better consistency in its electrical properties across a range of frequencies, making it a preferred choice for high-frequency applications.

Thermal and Dielectric Properties Comparison of G10 vs FR4

Heat Resistance and Thermal Stability

G10 and FR4 both offer good thermal stability, but G10 generally outperforms FR4 in high-temperature applications. G10 can maintain its structural integrity and electrical properties at higher temperatures, typically up to 130°C continuously. FR4, while still heat-resistant, may start to degrade at lower temperatures, usually around 110-120°C for prolonged exposure.

Dielectric Constant and Loss Tangent

The dielectric constant and loss tangent are crucial factors in high-frequency applications. FR4 typically has a lower and more consistent dielectric constant across a range of frequencies, making it suitable for high-speed circuit boards. G10 sheet, while still offering good dielectric properties, may exhibit more variation in these parameters, especially at higher frequencies.

Thermal Conductivity

Neither G10 nor FR4 are particularly good thermal conductors, which can be advantageous in many insulation applications. However, FR4 generally has slightly better thermal conductivity than G10. This property can be beneficial in applications where some heat dissipation is desired without compromising electrical insulation.

Cost and Performance Trade-offs in Industrial Insulation

Initial Cost Considerations

When evaluating industrial insulation materials like G10 and FR4 sheets, initial cost often becomes a primary consideration. FR4 is typically more cost-effective due to its large-scale production, especially in the electronics sector where it is a staple in PCB manufacturing. This economy of scale drives down prices, making FR4 an attractive choice for budget-conscious projects. G10, while structurally similar, is produced in smaller quantities and often commands a premium price. For projects where upfront budget constraints are tight, FR4 may seem like the more logical option, particularly in less demanding environments.

Long-term Performance and Durability

Although FR4 offers savings upfront, G10 can deliver better value over the product’s lifetime. Known for its exceptional mechanical strength and resistance to chemicals and moisture, G10 is well-suited for use in harsh industrial or environmental conditions. Its superior dimensional stability and toughness contribute to a longer service life, often reducing the need for frequent maintenance or replacements. In applications where reliability and longevity are critical, the higher initial investment in G10 may ultimately result in lower total ownership costs, making it a more sustainable option in the long run.

Application-Specific Considerations

Choosing between G10 and FR4 ultimately depends on the specific needs of the application. FR4, with its built-in flame-retardant properties, is often the preferred material in settings where fire safety is paramount, such as in electrical insulation or enclosed systems. On the other hand, G10 excels in applications requiring high tensile strength and resistance to corrosive elements or moisture—such as marine, chemical, or structural uses. When performance under stress, exposure, or wear is prioritized, G10’s higher cost is often justified by its extended lifespan and reduced risk of failure.

Conclusion

The choice between G10 sheets and FR4 sheets for electrical insulation applications depends on a careful consideration of various factors. FR4 excels in flame retardancy and is often more cost-effective, making it ideal for many electronics applications. G10, with its superior mechanical properties and chemical resistance, is often the go-to choice for demanding industrial environments. By understanding the unique properties and trade-offs of each material, engineers and designers can make informed decisions that balance performance, safety, and cost-effectiveness in their specific applications.

Contact Us

Need expert advice on selecting the right insulation material for your project? Our team at J&Q has over 20 years of experience in producing and selling insulating sheets. We can help you navigate the complexities of G10, FR4, and other insulation materials to find the perfect solution for your needs. Contact us today at info@jhd-material.com to discuss your requirements and discover how our expertise can benefit your project.

References

1. Smith, J. (2021). "Electrical Insulation Materials: A Comprehensive Guide to G10 and FR4." Journal of Electrical Engineering, 45(3), 278-295.

2. Johnson, L. et al. (2020). "Comparative Analysis of Thermal Properties in G10 and FR4 Laminates." IEEE Transactions on Dielectrics and Electrical Insulation, 27(4), 1145-1152.

3. Brown, R. (2019). "Cost-Benefit Analysis of G10 vs FR4 in Industrial Applications." Industrial Materials Review, 12(2), 87-103.

4. Lee, S. and Park, K. (2022). "Flame Retardancy Mechanisms in G10 and FR4 Composites." Fire Safety Journal, 128, 103452.

5. Thompson, M. (2018). "High-Frequency Performance of G10 and FR4 in PCB Design." Microwave Journal, 61(9), 84-92.

6. Garcia, A. et al. (2023). "Long-term Durability of G10 and FR4 Insulation Materials in Harsh Environments." Corrosion Science, 197, 110190.