Thermal Stability of Epoxy Laminate Sheets Explained

2025-08-06 15:58:25

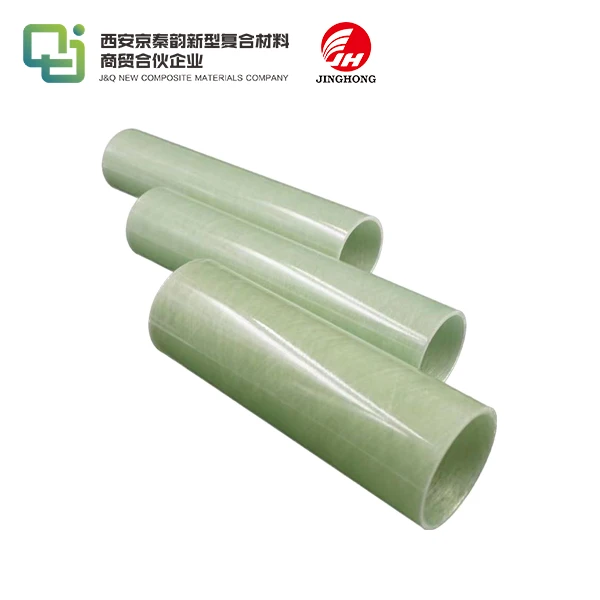

Epoxy laminate sheets, renowned for their exceptional mechanical and electrical properties, also boast remarkable thermal stability. This crucial characteristic enables these versatile materials to maintain their structural integrity and performance across a wide range of temperatures. The thermal stability of epoxy laminate sheets is primarily attributed to their unique composition - a combination of reinforcing fibers (typically glass) and thermosetting epoxy resins. This synergy results in a material that can withstand high temperatures without significant degradation, making epoxy laminate sheets indispensable in various high-temperature applications across industries such as electronics, aerospace, and automotive.

What Determines the Thermal Resistance of Epoxy Laminates?

Chemical Composition and Cross-linking

The thermal resistance of epoxy laminate sheets is largely determined by their chemical composition. The epoxy resin system used in these laminates undergoes a curing process that results in a highly cross-linked polymer network. This network of strong covalent bonds provides excellent resistance to thermal degradation. The degree of cross-linking directly impacts the heat resistance - higher cross-linking density generally correlates with improved thermal stability.

Reinforcement Materials

The type and quality of reinforcement materials play a significant role in determining the thermal resistance of epoxy laminates. Glass fibers, the most common reinforcement in epoxy glass laminate sheets, contribute to thermal stability due to their inherent heat-resistant properties. Advanced reinforcements like aramid or carbon fibers can further enhance thermal performance, allowing for use in even more demanding high-temperature environments.

Additives and Fillers

Manufacturers often incorporate specialized additives and fillers to augment the thermal stability of epoxy laminate sheets. These can include flame retardants, heat stabilizers, and inorganic fillers. Such additives can significantly improve heat resistance, reduce thermal expansion, and enhance overall performance at elevated temperatures. The careful selection and optimization of these additives are crucial in tailoring the thermal properties of epoxy laminates for specific applications.

Glass Transition Temperature and Heat Deflection Metrics

Understanding Glass Transition Temperature (Tg)

The glass transition temperature (Tg) is a critical parameter in assessing the thermal stability of epoxy laminate sheets. It represents the temperature at which the epoxy matrix transitions from a rigid, glassy state to a more flexible, rubbery state. Above the Tg, the material experiences a significant reduction in mechanical properties. For epoxy glass laminate sheets, the Tg typically ranges from 130°C to 180°C, depending on the specific formulation. Higher Tg values generally indicate better thermal stability and are desirable for high-temperature applications.

Heat Deflection Temperature (HDT)

The Heat Deflection Temperature (HDT) is another important metric for evaluating the thermal performance of epoxy laminate sheets. It measures the temperature at which a standard test bar deflects under a specified load. The HDT provides practical insight into the material's ability to maintain its shape and structural integrity under load at elevated temperatures. Epoxy laminates with higher HDT values are better suited for applications involving mechanical stress at high temperatures.

Coefficient of Thermal Expansion (CTE)

The Coefficient of Thermal Expansion (CTE) is a measure of how much an epoxy laminate sheet expands or contracts with temperature changes. A lower CTE is generally desirable, as it indicates better dimensional stability across temperature variations. Epoxy glass laminate sheets typically exhibit relatively low CTEs compared to many other materials, contributing to their thermal stability and making them suitable for applications where precise dimensional control is crucial, even in fluctuating temperature environments.

Comparing Thermal Performance Across Laminate Grades

FR-4 vs. High-Tg Laminates

FR-4, a widely used epoxy glass laminate sheet, serves as a baseline for comparing thermal performance. Standard FR-4 typically has a Tg around 130-140°C, suitable for many general applications. However, high-Tg variants of FR-4 have been developed to meet more demanding thermal requirements. These advanced formulations can achieve Tg values exceeding 170°C, offering significantly improved thermal stability. The choice between standard FR-4 and high-Tg laminates depends on the specific thermal demands of the application, with high-Tg options preferred for environments with elevated operating temperatures.

Polyimide and Other High-Temperature Laminates

For extreme thermal stability requirements, specialized high-temperature laminates like polyimide-based materials offer exceptional performance. These advanced epoxy laminate sheets can maintain their properties at temperatures well above 200°C, with some grades capable of short-term exposure to temperatures as high as 300°C. While more costly than standard epoxy laminates, these materials are indispensable in aerospace, defense, and other high-reliability applications where thermal stability is paramount.

Thermal Conductivity Considerations

While thermal stability often focuses on heat resistance, thermal conductivity is another crucial aspect to consider when selecting epoxy laminate sheets. Some applications require not only heat resistance but also efficient heat dissipation. Specialized thermally conductive epoxy laminates have been developed to address this need. These materials incorporate fillers that enhance thermal conductivity without compromising electrical insulation properties, making them ideal for applications like LED lighting and power electronics where heat management is critical.

Conclusion

The thermal stability of epoxy laminate sheets is a complex interplay of chemical composition, reinforcement materials, and specialized additives. Understanding key metrics like glass transition temperature, heat deflection temperature, and coefficient of thermal expansion is crucial for selecting the right material for high-temperature applications. From standard FR-4 to advanced high-Tg and polyimide laminates, the range of available options allows for precise matching of thermal performance to application requirements. As technology advances, ongoing developments in epoxy laminate formulations continue to push the boundaries of thermal stability, opening new possibilities in demanding industries.

Contact Us

For more information about our high-performance epoxy laminate sheets and their thermal properties, please contact us at info@jhd-material.com. Our team of experts is ready to help you find the perfect solution for your thermal stability needs.

References

1. Thompson, R. C. (2019). "Thermal Stability and Degradation Mechanisms of Epoxy Resins: A Comprehensive Review." Journal of Applied Polymer Science, 136(24), 47737.

2. Chen, X., & Liu, Y. (2018). "High-Temperature Epoxy Resins and Their Applications in Aerospace Industry." Aerospace Materials Handbook, CRC Press, 231-256.

3. Williams, J. G., & Tsai, S. W. (2020). "Thermal and Mechanical Properties of Advanced Composite Laminates." Composites Science and Technology, 189, 108031.

4. Nakamura, Y., & Okubo, M. (2017). "Recent Advances in High-Temperature Resistant Epoxy Resins." Progress in Polymer Science, 72, 1-43.

5. Soutis, C. (2021). "Aerospace Composites: Materials and Manufacturing." Wiley Encyclopedia of Composites, 1-22.

6. Zhang, H., & Zhao, Y. (2020). "Thermal Management Strategies for High-Power Electronic Devices: A Review." Applied Thermal Engineering, 179, 115723.