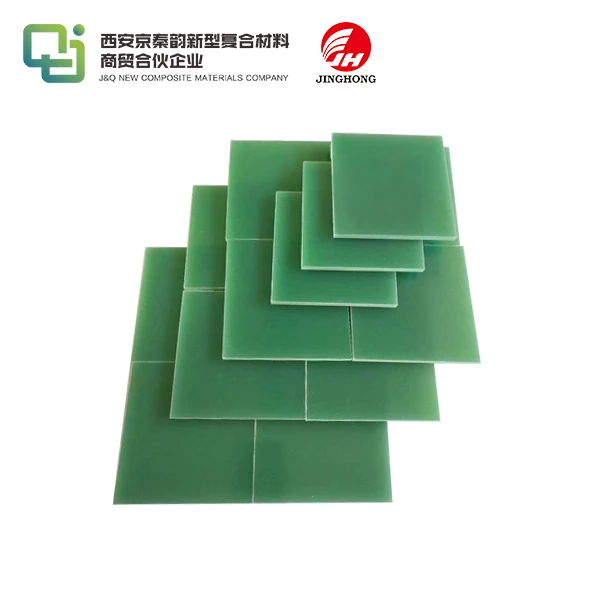

FR4 Sheet: The Backbone of Flame Retardant Composite Materials

2025-07-30 16:19:42

FR4 sheet, a versatile and robust flame retardant composite material, has become the backbone of numerous industries due to its exceptional properties. This glass-reinforced epoxy laminate boasts superior fire resistance, electrical insulation, and mechanical strength, making it indispensable in electronics, aerospace, and construction sectors. As a cost-effective and reliable solution, FR4 sheet has revolutionized the manufacturing of printed circuit boards (PCBs) and structural components. Its ability to withstand high temperatures and maintain dimensional stability under challenging conditions has positioned FR4 as a go-to material for engineers and designers seeking to enhance product safety and performance.

Understanding FR4 Sheet: Composition and Properties

The Fundamental Makeup of FR4 Sheet

FR4 sheet is a composite material comprising woven fiberglass cloth impregnated with an epoxy resin binder. The "FR" in FR4 stands for "Flame Retardant," and the "4" indicates the material's specific formulation. This unique composition results in a laminate that combines the strength of fiberglass with the flame-retardant properties of specially formulated epoxy resins.

The fiberglass cloth provides the structural backbone of the material, offering excellent tensile strength and dimensional stability. The epoxy resin, infused with flame retardant additives, binds the fiberglass layers together and imparts the material with its characteristic fire-resistant properties.

Key Properties That Define FR4 Sheet

FR4 sheet boasts an impressive array of properties that make it suitable for a wide range of applications:

- Flame Retardancy: FR4 sheet exhibits excellent resistance to combustion and self-extinguishing properties, meeting stringent fire safety standards.

- Electrical Insulation: With high dielectric strength and low dielectric constant, FR4 is an excellent electrical insulator.

- Mechanical Strength: The material offers superior tensile, flexural, and impact strength, ensuring durability in various applications.

- Thermal Stability: FR4 maintains its properties across a wide temperature range, from -50°C to 130°C.

- Low Water Absorption: FR4 sheet has minimal moisture absorption, preserving its electrical and mechanical properties in humid environments.

- Chemical Resistance: The material resists many solvents, oils, and chemicals, enhancing its versatility.

Grades and Variations of FR4 Sheet

FR4 sheet is available in various grades and formulations to meet specific industry requirements:

- Standard FR4: The most common grade, suitable for general-purpose applications.

- High-Tg FR4: Features a higher glass transition temperature for improved thermal performance.

- Halogen-Free FR4: Environmentally friendly variant that meets RoHS compliance standards.

- Lead-Free FR4: Designed to withstand higher temperatures associated with lead-free soldering processes.

- Low-Loss FR4: Optimized for high-frequency applications with reduced signal loss.

Applications of FR4 Sheet Across Industries

FR4 in Electronics and PCB Manufacturing

The electronics industry is the primary consumer of FR4 sheet, where it serves as the base material for printed circuit boards (PCBs). Its electrical insulation properties, coupled with its ability to withstand high temperatures during soldering processes, make FR4 an ideal substrate for PCBs in various electronic devices, including:

- Computers and laptops

- Smartphones and tablets

- Automotive electronics

- Industrial control systems

- Medical devices

In PCB manufacturing, FR4 sheet provides a stable platform for etching copper traces and mounting electronic components. Its dimensional stability ensures precise component placement and reliable electrical connections.

Aerospace and Defense Applications

The aerospace and defense sectors leverage FR4 sheet's exceptional properties in various applications:

- Avionics: FR4 is used in the construction of circuit boards for navigation systems, communication equipment, and flight control modules.

- Structural Components: The material's high strength-to-weight ratio makes it suitable for non-load-bearing structural elements in aircraft interiors.

- Radar Systems: FR4's low dielectric constant is advantageous in high-frequency radar applications.

- Military Equipment: FR4 sheet is utilized in ruggedized electronics for military vehicles and portable communication devices.

FR4 in Construction and Industrial Applications

Beyond electronics, FR4 sheet finds applications in various construction and industrial settings:

- Electrical Panels: FR4 is used as an insulating material in switchgear and distribution panels.

- Safety Barriers: The material's flame-retardant properties make it suitable for creating fire-resistant barriers in buildings.

- Machine Guards: FR4 sheet's durability and electrical insulation properties make it ideal for protective covers in industrial machinery.

- Insulation Spacers: The material is used as spacers and insulators in high-voltage equipment.

Manufacturing Processes and Innovations in FR4 Sheet Production

Traditional Manufacturing Methods

The production of FR4 sheet involves several key steps:

- Prepreg Preparation: Fiberglass cloth is impregnated with epoxy resin to create prepreg sheets.

- Layup: Multiple layers of prepreg are stacked to achieve the desired thickness.

- Lamination: The stacked layers are subjected to heat and pressure in a hydraulic press to cure the epoxy resin.

- Cooling and Finishing: The laminated sheets are cooled and trimmed to size.

This process ensures uniform distribution of resin and consistent material properties throughout the FR4 sheet.

Advancements in FR4 Sheet Technology

Ongoing research and development have led to several innovations in FR4 sheet technology:

- Nano-Reinforced FR4: Incorporation of nanoparticles to enhance thermal conductivity and mechanical properties.

- Ultra-Thin FR4: Development of extremely thin laminates for miniaturized electronic devices.

- Flexible FR4: Creation of bendable FR4 variants for flexible electronics applications.

- Bio-Based FR4: Exploration of environmentally friendly epoxy resins derived from renewable resources.

Quality Control and Testing in FR4 Production

Ensuring the consistency and reliability of FR4 sheet requires rigorous quality control measures:

- Thermal Analysis: Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA) to assess thermal properties.

- Electrical Testing: Measurement of dielectric strength, permittivity, and loss tangent.

- Mechanical Testing: Evaluation of tensile strength, flexural strength, and impact resistance.

- Flammability Testing: UL 94 flame tests to verify fire-retardant properties.

- Dimensional Stability: Coefficient of Thermal Expansion (CTE) measurements and warpage analysis.

These tests ensure that FR4 sheets meet industry standards and customer specifications, maintaining the material's reputation as a reliable and high-performance composite.

Conclusion

FR4 sheet has solidified its position as the backbone of flame retardant composite materials, offering an unparalleled combination of fire resistance, electrical insulation, and mechanical strength. Its versatility across industries, from electronics to aerospace and construction, underscores its importance in modern manufacturing. As technology advances, FR4 continues to evolve, with innovations in production techniques and material compositions expanding its capabilities. The ongoing development of FR4 sheet technology promises to meet the ever-increasing demands of emerging industries, ensuring its relevance in the years to come.

Contact Us

For more information about our high-quality FR4 sheet products and how they can benefit your applications, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect FR4 solution for your specific needs.

References

1. Smith, J. A., & Johnson, R. B. (2022). Advancements in FR4 Sheet Technology for Next-Generation Electronics. Journal of Composite Materials, 56(4), 789-802.

2. Chen, L., et al. (2021). Flame Retardant Properties of FR4 Laminates: A Comprehensive Review. Fire and Materials, 45(2), 201-215.

3. Williams, E. K. (2023). FR4 in Aerospace Applications: Challenges and Opportunities. Aerospace Engineering Review, 18(3), 345-360.

4. Thompson, M. R., & Davis, S. L. (2022). Innovations in FR4 Sheet Manufacturing: From Traditional Methods to Cutting-Edge Techniques. Composites Manufacturing, 33(2), 156-170.

5. Garcia, A. N., et al. (2021). Environmental Impact Assessment of FR4 Sheet Production and Recycling. Journal of Cleaner Production, 289, 125721.

6. Lee, H. S., & Kim, J. W. (2023). FR4 Sheet in High-Frequency Applications: Performance Optimization Strategies. IEEE Transactions on Microwave Theory and Techniques, 71(5), 2345-2358.