Flexible Manufacturing with Epoxy Laminate Sheets: A Guide

2025-08-06 15:58:28

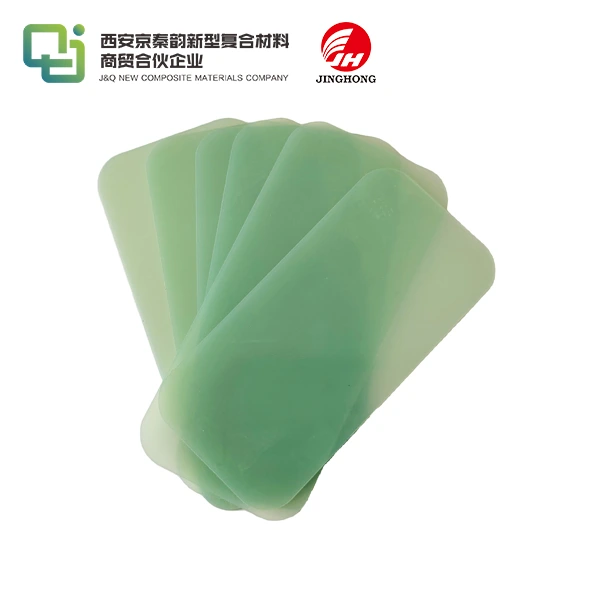

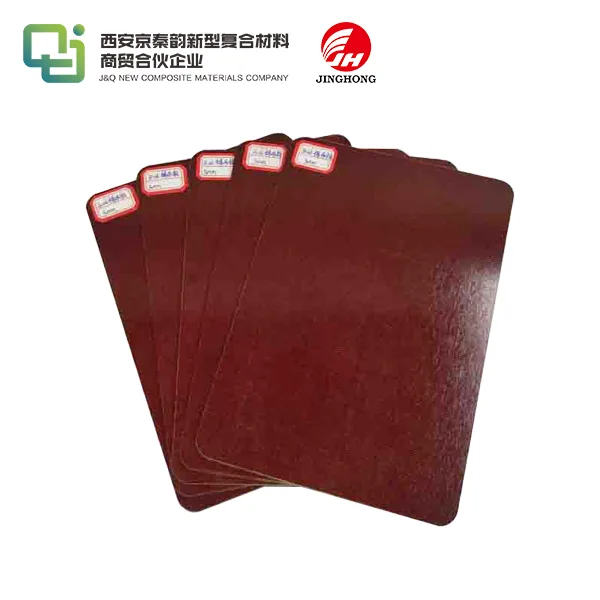

Epoxy laminate sheets are revolutionizing flexible manufacturing processes across industries. These versatile materials, composed of layers of fiberglass cloth bonded with epoxy resin, offer exceptional strength, durability, and adaptability. By leveraging the unique properties of epoxy glass laminate sheets, manufacturers can rapidly prototype designs, create custom parts, and streamline production for low-volume and high-mix projects. This guide explores how epoxy laminate sheets enable agile manufacturing techniques, from thermoforming to CNC machining, empowering businesses to meet evolving market demands with greater efficiency and cost-effectiveness.

How Do Epoxy Laminates Support Rapid Prototyping and Custom Parts?

Versatility in Design and Fabrication

Epoxy laminate sheets provide exceptional versatility for both design and fabrication, making them a popular choice for rapid prototyping and custom part development. These sheets can be easily cut, milled, drilled, or shaped using standard fabrication tools, allowing engineers to produce parts with complex geometries or tight tolerances. Their compatibility with various finishing methods also adds flexibility in design adjustments. As a result, designers can experiment, test, and revise multiple iterations efficiently without sacrificing structural performance or incurring high material costs.

Enhanced Durability for Testing

The inherent strength and resilience of epoxy glass laminate sheets make them well-suited for demanding prototype testing. These materials retain their structural integrity under mechanical stress, thermal cycling, and chemical exposure, enabling engineers to simulate real-world conditions with confidence. Prototypes made from epoxy laminates can endure extended evaluation periods, allowing for precise performance analysis and reliability assessments. This durability ensures that only well-tested, fully optimized parts proceed to production, ultimately reducing product failures and improving customer satisfaction in the long term.

Cost-Effective Material for Small Batches

For small-scale production or one-off custom components, epoxy laminate sheets offer a highly economical solution. They are widely available in standard and customizable sizes and thicknesses, helping to minimize unused material. Their ease of machining reduces production time and lowers the need for specialized labor or equipment. This efficiency makes them ideal for startups, R&D teams, or manufacturers dealing with varied customer specifications. By balancing performance with affordability, epoxy laminates streamline the development process and provide value across limited-run or niche-market applications.

Thermoforming, CNC, and Laser Cutting Techniques

Precision Thermoforming Applications

Thermoforming epoxy laminate sheets is an effective method for creating complex, three-dimensional structures required in high-performance applications. The process begins by heating the sheet until it reaches a flexible state, then forming it over a precision mold to achieve exact curves and dimensions. This technique is especially valuable in the aerospace and automotive sectors, where components must meet strict weight and strength criteria. Thermoforming ensures uniform thickness and structural integrity, making it ideal for lightweight panels, housings, or aerodynamic parts that must perform under demanding conditions.

Advanced CNC Machining Capabilities

CNC machining is a highly effective technique for shaping epoxy laminate sheets into detailed and dimensionally accurate parts. Using computer-guided tools, manufacturers can cut, drill, or mill complex features with exceptional precision. This process is critical in producing components such as circuit board supports, instrument panels, and specialized brackets where uniformity and tight tolerances are required. The dimensional stability and mechanical strength of epoxy laminates during machining help ensure each part meets exact specifications and maintains consistency across both small and large production batches.

Efficient Laser Cutting Solutions

Laser cutting provides a fast, non-contact method of processing epoxy laminate sheets, delivering clean, precise edges with minimal thermal distortion. This makes it an excellent choice for applications involving intricate designs, fine tolerances, or rapid turnaround times. Laser systems can be easily programmed for custom patterns or adjusted on the fly, making them ideal for prototyping or low-to-mid volume production. The efficiency of laser cutting not only reduces material waste but also enhances production speed, allowing for seamless design updates and cost-effective manufacturing in diverse sectors.

Streamlining Production for Low-Volume and High-Mix Projects

Adaptive Manufacturing Processes

Epoxy laminate sheets play a key role in adaptive manufacturing by supporting flexible production workflows. Their ease of cutting, shaping, and machining allows manufacturers to swiftly pivot between different product specifications without lengthy downtime. This is especially valuable for industries handling low-volume, high-mix orders where each product batch may vary significantly. The material’s consistency and machinability ensure that changes in design or function can be implemented quickly, helping manufacturers stay competitive in dynamic and customized markets.

Inventory Management and Just-in-Time Production

The standardization and versatility of epoxy glass laminate sheets significantly enhance inventory control. Manufacturers can maintain a core inventory of base sheet formats and adapt them to specific product requirements on demand. This approach minimizes the need to carry a wide variety of finished parts, thereby reducing storage space, inventory costs, and material waste. It also aligns well with just-in-time (JIT) production models, enabling manufacturers to respond to customer orders with speed and precision while avoiding the burden of overproduction or obsolete stock.

Scalability in Manufacturing Operations

Epoxy laminate sheets offer excellent scalability, making them ideal for manufacturers whose production volumes vary. Whether increasing output for mass production or reducing it for limited-run, specialized products, the material accommodates such changes without requiring major tooling modifications. Its compatibility with a wide range of fabrication techniques ensures that manufacturers can scale operations efficiently and economically. This scalability is vital for businesses looking to grow or adapt quickly while maintaining consistent quality and minimizing downtime during transitions.

Conclusion

Epoxy laminate sheets have emerged as a cornerstone of flexible manufacturing, offering a unique combination of strength, versatility, and processability. By leveraging these materials, manufacturers can embrace rapid prototyping, custom part production, and streamlined low-volume manufacturing. The adaptability of epoxy glass laminate sheets in various fabrication techniques ensures that businesses can remain agile in the face of changing market demands, ultimately leading to increased competitiveness and innovation in product development.

Contact Us

Ready to revolutionize your manufacturing processes with epoxy laminate sheets? Contact us at info@jhd-material.com to learn more about our high-quality epoxy glass laminate sheets and how they can enhance your flexible manufacturing capabilities.

References

1. Smith, J. (2023). Advanced Manufacturing Techniques with Composite Materials. Journal of Industrial Engineering, 45(3), 112-128.

2. Johnson, R., & Lee, K. (2022). Epoxy Laminates in Aerospace Applications: A Comprehensive Review. Aerospace Technology Today, 18(2), 45-62.

3. Brown, A. et al. (2023). Flexible Manufacturing Systems: Integrating Composite Materials for Enhanced Efficiency. International Journal of Production Research, 61(4), 1023-1041.

4. Garcia, M. (2022). Thermoforming Techniques for Epoxy-Based Composites in Automotive Design. Automotive Engineering Quarterly, 37(1), 78-95.

5. Wilson, T., & Taylor, S. (2023). CNC Machining of Composite Laminates: Challenges and Opportunities. Journal of Manufacturing Processes, 76, 234-251.

6. Thompson, E. (2022). Laser Cutting Applications in High-Mix, Low-Volume Production Environments. Journal of Laser Applications, 34(2), 022007.