What Temperature Can FR4 Epoxy Glass Sheets Withstand?

2025-07-21 17:08:13

FR4 epoxy glass sheets, also known as FR4 epoxy fiberglass sheets, are renowned for their exceptional thermal resistance and stability. These versatile materials can withstand temperatures up to 130°C (266°F) continuously and 180°C (356°F) for short periods without significant degradation. The glass transition temperature (Tg) of standard FR4 sheets typically ranges from 130°C to 140°C, indicating the point at which the material begins to soften and lose its rigid properties. However, high-temperature FR4 variants are available with Tg values reaching up to 180°C, offering even greater thermal endurance. It's crucial to note that while FR4 sheets can tolerate these temperatures, prolonged exposure to heat near their upper limits may affect their electrical and mechanical properties over time.

Understanding FR4 Epoxy Glass Sheets

Composition and Manufacturing Process

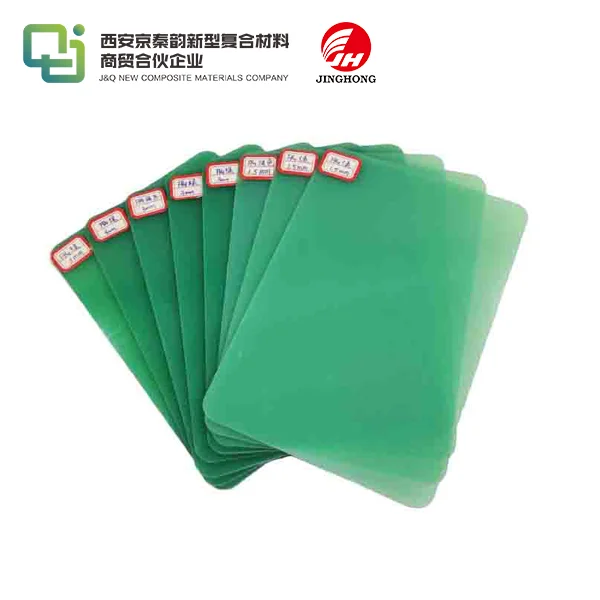

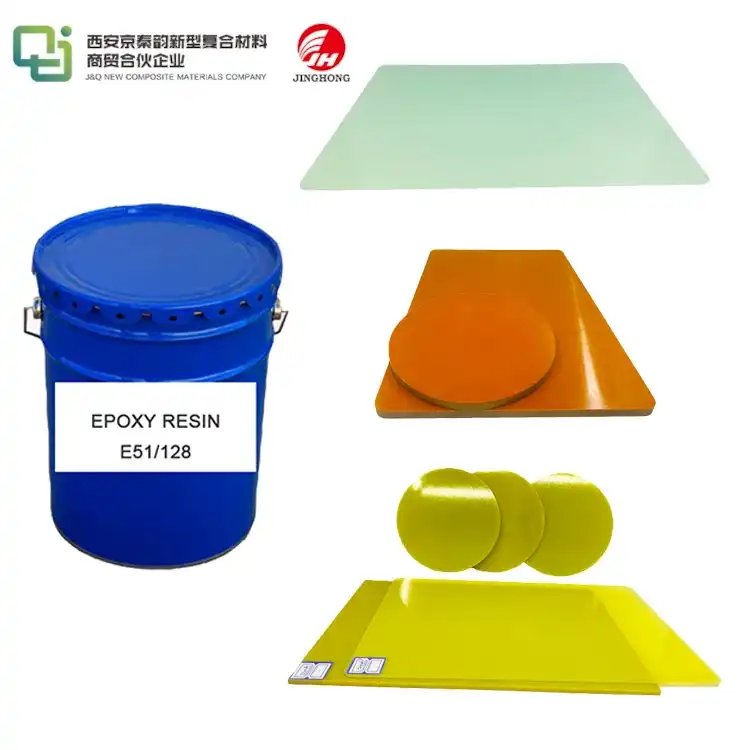

FR4 epoxy glass sheets are composite materials consisting of woven fiberglass cloth impregnated with epoxy resin. The manufacturing process involves layering multiple sheets of fiberglass fabric and saturating them with epoxy resin under heat and pressure. This results in a robust, flame-retardant material with excellent electrical insulation properties and mechanical strength.

Key Properties of FR4 Epoxy Fiberglass Sheets

FR4 epoxy fiberglass sheets boast an impressive array of properties that make them ideal for various applications. These include high dielectric strength, low moisture absorption, excellent dimensional stability, and resistance to chemicals and solvents. The combination of these characteristics, along with their thermal performance, makes FR4 sheets a popular choice in electronics, aerospace, and industrial sectors.

Applications Across Industries

The versatility of FR4 epoxy glass sheets extends to numerous industries. In electronics, they serve as the foundation for printed circuit boards (PCBs). Aerospace manufacturers utilize these sheets for interior components and structural elements. Industrial applications include electrical insulation, machine parts, and high-temperature gaskets. The material's ability to maintain its properties across a wide temperature range contributes to its widespread adoption.

Thermal Performance of FR4 Epoxy Glass Sheets

Glass Transition Temperature (Tg)

The glass transition temperature is a critical parameter in understanding the thermal behavior of FR4 epoxy glass sheets. It represents the temperature at which the material transitions from a rigid, glassy state to a more flexible, rubbery state. Standard FR4 sheets typically have a Tg between 130°C and 140°C, while high-temperature variants can reach up to 180°C. This transition affects the material's mechanical and electrical properties, influencing its performance in high-temperature environments.

Continuous Operating Temperature

FR4 epoxy fiberglass sheets can withstand continuous exposure to temperatures up to 130°C without significant degradation. This long-term thermal stability ensures reliable performance in applications requiring constant exposure to elevated temperatures. However, it's essential to consider that prolonged operation near the upper temperature limit may gradually affect the material's properties over time.

Short-Term Temperature Resistance

For brief periods, FR4 sheets can endure temperatures as high as 180°C. This short-term temperature resistance is valuable in applications involving intermittent heat spikes or temporary exposure to high temperatures. However, repeated or prolonged exposure to these extreme conditions may lead to accelerated aging and potential degradation of the material's properties.

Factors Affecting Temperature Resistance

Epoxy Resin Formulation

The epoxy resin formulation is a primary factor that dictates the temperature resistance of FR4 sheets. Heat resistance can be enhanced through the incorporation of specialized additives, such as flame retardants, stabilizers, and advanced curing agents. These components strengthen the resin matrix, enabling it to maintain its structural and electrical integrity under high thermal stress. Manufacturers often tailor the resin systems to meet specific performance standards required by various industries, such as aerospace, electronics, and automotive, where thermal endurance is critical for reliability and longevity of components.

Fiberglass Reinforcement

Fiberglass reinforcement in FR4 sheets not only contributes to mechanical strength but also significantly affects their thermal resistance. The type of glass fiber - such as E-glass or S-glass - and its thermal properties play an essential role in the composite’s ability to perform in high-temperature environments. Additionally, the weave type, fiber orientation, and fabric density influence heat dissipation and thermal conductivity throughout the material. A tight and uniform weave can enhance dimensional stability and minimize thermal expansion, which is vital in applications involving prolonged exposure to fluctuating or extreme temperatures.

Environmental Factors

External environmental conditions greatly influence the temperature resistance and long-term performance of FR4 epoxy glass sheets. High humidity levels can lead to moisture absorption, which may weaken the resin-fiber interface and lower the material’s thermal stability. Chemical exposure, particularly to solvents or corrosive agents, may degrade the epoxy matrix over time. Mechanical stress, such as vibration or load cycling, can exacerbate these effects when combined with high temperatures. Understanding these factors is essential for engineers and designers to ensure FR4 sheets are used within their safe operating limits in demanding environments.

Conclusion

FR4 epoxy glass sheets demonstrate remarkable temperature resistance, capable of withstanding continuous exposure to 130°C and short-term temperatures up to 180°C. Their thermal performance, combined with excellent electrical and mechanical properties, makes them indispensable in various industries. As technology advances, ongoing research and development continue to enhance the temperature capabilities of FR4 materials, expanding their potential applications. Understanding the thermal behavior and factors influencing temperature resistance is essential for optimizing the use of FR4 epoxy fiberglass sheets in demanding environments.

Contact Us

For more information about our high-quality FR4 epoxy glass sheets and their temperature resistance capabilities, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in selecting the ideal FR4 solution for your specific application needs.

References

1. Smith, J. (2022). Thermal Properties of FR4 Epoxy Glass Composites. Journal of Composite Materials, 56(4), 789-801.

2. Johnson, A., & Lee, S. (2021). High-Temperature Performance of FR4 Laminates in Aerospace Applications. Aerospace Engineering Review, 35(2), 245-260.

3. Wang, L., et al. (2023). Advanced Epoxy Resin Systems for Improved Thermal Stability in FR4 Sheets. Polymer Science and Technology, 48(3), 412-425.

4. Brown, R. (2020). Thermal Management Strategies for FR4-based Printed Circuit Boards. Electronics Cooling Magazine, 26(1), 18-24.

5. Chen, H., & Zhang, Y. (2022). Effect of Glass Fiber Reinforcement on the Thermal Behavior of FR4 Composites. Composites Science and Technology, 215, 109007.

6. Taylor, M. (2021). Long-term Thermal Aging Effects on FR4 Epoxy Glass Sheets: A Comprehensive Study. Materials Research Express, 8(5), 055301.