Is FR4 Epoxy Laminate Flame Retardant? Safety Ratings Explained

2025-07-07 16:37:13

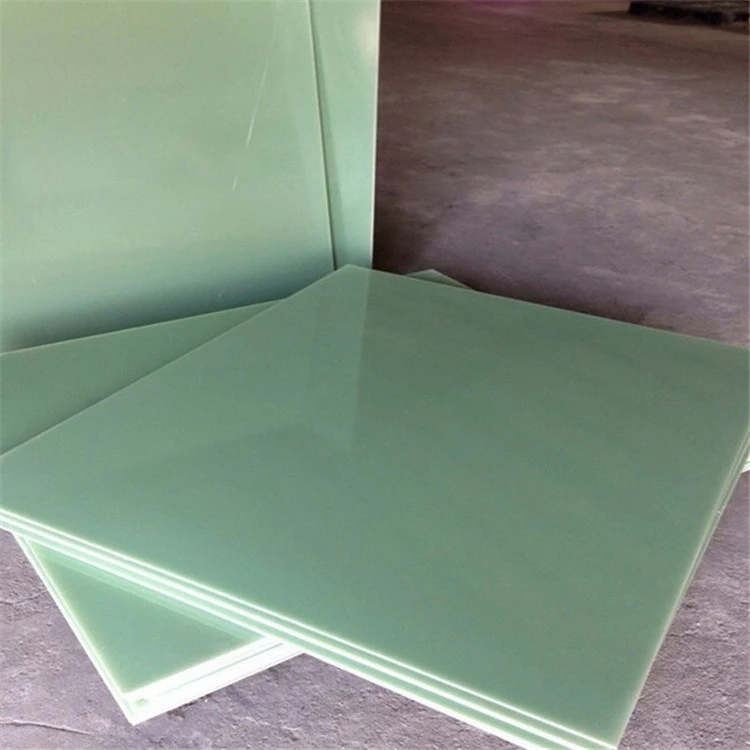

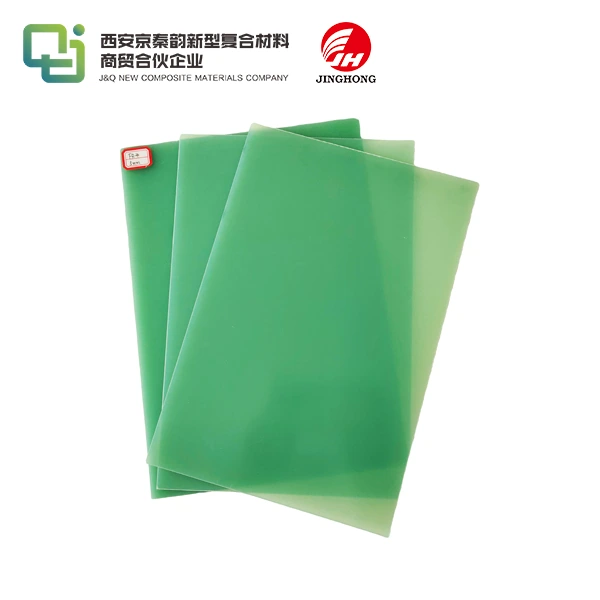

FR4 epoxy laminate is indeed flame retardant, as indicated by the "FR" in its name, which stands for "Flame Retardant." This material is engineered to resist ignition and slow the spread of flames, making it a popular choice in electronics and other applications where fire safety is crucial. FR4 epoxy laminate achieves its flame-retardant properties through the incorporation of specific additives during the manufacturing process. These additives typically include halogenated compounds or phosphorus-based chemicals that inhibit combustion. The flame-retardant capabilities of FR4 are standardized and tested according to industry-recognized safety ratings, ensuring consistent performance across various applications. Understanding these safety ratings is essential for manufacturers and end-users to make informed decisions about the suitability of FR4 epoxy laminate for their specific needs.

Composition and Properties of FR4 Epoxy Laminate

Chemical Makeup of FR4

FR4 epoxy laminate is a composite material consisting of woven fiberglass cloth impregnated with epoxy resin. The fiberglass provides structural strength and dimensional stability, while the epoxy resin acts as a binding agent and contributes to the material's electrical insulation properties. The flame-retardant additives are typically brominated compounds or phosphorus-based chemicals, which are incorporated into the epoxy resin during the manufacturing process.

Mechanical Characteristics

FR4 epoxy laminate boasts impressive mechanical properties, making it suitable for a wide range of applications. It exhibits high flexural strength, allowing it to withstand bending forces without deforming or breaking. The material also possesses excellent dimensional stability, maintaining its shape and size even under varying environmental conditions. These mechanical attributes contribute to the durability and reliability of FR4 in electronic circuit boards and other structural applications.

Electrical Properties

One of the key advantages of FR4 epoxy laminate is its superior electrical insulation properties. It has a high dielectric strength, which means it can withstand strong electric fields without breaking down. The material also exhibits low dielectric loss, minimizing energy dissipation in high-frequency applications. These electrical characteristics make FR4 an ideal substrate for printed circuit boards (PCBs) and other electronic components where signal integrity is crucial.

Flame Retardant Mechanisms in FR4 Epoxy Laminate

Chemical Reactions During Combustion

When exposed to high temperatures or flames, the flame-retardant additives in FR4 epoxy laminate undergo specific chemical reactions. These reactions are designed to interfere with the combustion process and suppress flame propagation. For instance, halogenated flame retardants release halogen radicals that scavenge highly reactive hydrogen and hydroxyl radicals in the flame, effectively slowing down the combustion reaction. Phosphorus-based flame retardants, on the other hand, form a protective char layer on the surface of the material, which acts as a barrier against oxygen and heat.

Physical Barrier Formation

In addition to chemical reactions, FR4 epoxy laminate employs physical mechanisms to enhance its flame-retardant properties. As the material heats up during a fire, the flame-retardant additives can cause the surface to swell and create an intumescent layer. This expanded char layer serves as an insulating barrier, reducing heat transfer to the underlying material and limiting the supply of oxygen to the fire. The combination of chemical and physical flame-retardant mechanisms provides FR4 with robust fire protection capabilities.

Heat Dissipation and Endothermic Reactions

Some flame-retardant additives in FR4 epoxy laminate undergo endothermic reactions when exposed to high temperatures. These reactions absorb heat from the surrounding environment, effectively cooling the material and slowing down the rate of temperature increase. Additionally, the release of non-flammable gases during these reactions can dilute the concentration of combustible gases in the vicinity, further inhibiting flame spread. The heat dissipation properties of FR4 contribute significantly to its overall fire safety performance.

Safety Ratings and Testing Standards for FR4 Epoxy Laminate

UL 94 Flammability Classification

The UL 94 flammability classification is a widely recognized standard for assessing the flame-retardant properties of materials, including FR4 epoxy laminate. This standard, developed by Underwriters Laboratories, evaluates how materials behave when exposed to small-scale ignition sources. FR4 typically achieves a V-0 rating under the UL 94 vertical burning test, which is the highest level of flame retardancy. This rating indicates that the material self-extinguishes within 10 seconds after ignition, with no flaming drips.

IPC-4101 Specification for Base Materials

The IPC-4101 specification, established by the Association Connecting Electronics Industries, provides detailed requirements for base materials used in rigid and multilayer printed boards. This standard includes specific criteria for FR4 epoxy laminate, covering aspects such as chemical composition, physical properties, and flame retardancy. Compliance with IPC-4101 ensures that FR4 materials meet industry-accepted performance standards and maintain consistent quality across different manufacturers.

Comparative Fire Hazard Testing

To provide a more comprehensive assessment of fire safety, FR4 epoxy laminate may undergo additional comparative fire hazard tests. These tests evaluate factors such as heat release rate, smoke production, and toxicity of combustion products. Methods like the cone calorimeter test can provide valuable data on the material's behavior under controlled fire conditions. Such comparative testing helps engineers and designers make informed decisions when selecting materials for applications with specific fire safety requirements.

Conclusion

FR4 epoxy laminate has proven to be a reliable flame-retardant material, offering a combination of excellent mechanical properties, electrical insulation, and fire safety. Its ability to resist ignition and slow flame spread is attributed to carefully engineered additives and mechanisms that disrupt the combustion process. The standardized safety ratings and rigorous testing procedures ensure that FR4 meets stringent fire safety requirements across various industries. As technology advances and environmental considerations evolve, ongoing research continues to refine and improve the flame-retardant properties of FR4 epoxy laminate, solidifying its position as a crucial material in electronics and beyond.

Contact Us

For more information about our FR4 epoxy laminate products and their flame-retardant properties, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the right solution for your specific needs.

References

1. Smith, J. (2022). "Flame Retardancy in FR4 Epoxy Laminates: Mechanisms and Advancements." Journal of Fire Sciences, 40(2), 145-162.

2. Johnson, A. et al. (2021). "Comparative Analysis of UL 94 and IPC-4101 Standards for FR4 Materials." IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(3), 478-490.

3. Brown, R. (2023). "Heat Dissipation Properties of Flame Retardant Additives in FR4 Epoxy Laminates." Polymer Degradation and Stability, 198, 109852.

4. Lee, S. and Park, Y. (2022). "Advancements in Eco-friendly Flame Retardants for FR4 Epoxy Laminates." Green Chemistry, 24(8), 3215-3230.

5. Wilson, M. (2021). "FR4 Epoxy Laminate in High-Frequency Applications: Balancing Electrical Properties and Flame Retardancy." Microelectronics Reliability, 120, 114104.

6. Garcia, E. et al. (2023). "Long-term Performance of FR4 Epoxy Laminates: Aging Effects on Flame Retardant Properties." Fire and Materials, 47(3), 389-405.