What Makes High Temperature Epoxy Sheets So Durable?

2025-07-01 17:12:05

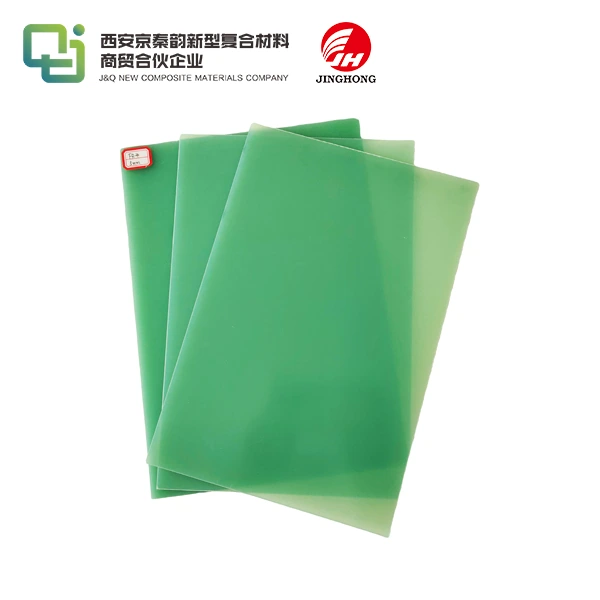

High temperature epoxy sheets are renowned for their exceptional durability, making them a go-to material in various industries. Their resilience stems from a unique combination of chemical composition, manufacturing processes, and inherent properties. The epoxy resin matrix, reinforced with high-strength fibers, creates a robust structure capable of withstanding extreme temperatures and harsh conditions. This synergy results in sheets that resist thermal degradation, maintain dimensional stability, and exhibit impressive mechanical strength. The cross-linked polymer structure of epoxy resins contributes significantly to their durability, forming a tight network that resists chemical attacks and physical wear. These factors collectively ensure that high temperature epoxy sheets remain resilient and reliable in demanding applications.

Chemical Composition and Structure

Advanced Polymer Technology

The foundation of high temperature epoxy sheets' durability lies in their advanced polymer technology. These sheets are composed of highly crosslinked epoxy resins, which form a three-dimensional network of molecular bonds. This intricate structure provides exceptional resistance to heat, chemicals, and mechanical stress. The polymer chains interlock tightly, creating a barrier that prevents degradation and maintains the material's integrity even under extreme conditions.

Reinforcement Materials

To enhance their durability further, high temperature epoxy sheets often incorporate reinforcement materials. Glass fibers, carbon fibers, or aramid fibers are commonly used to bolster the epoxy matrix. These reinforcements significantly improve the sheet's tensile strength, impact resistance, and overall toughness. The synergistic relationship between the epoxy resin and reinforcement fibers results in a composite material that outperforms traditional materials in terms of durability and longevity.

Additives and Modifiers

Manufacturers often include specialized additives and modifiers in the epoxy formulation to tailor the sheets' properties for specific applications. These additives can enhance UV resistance, improve flame retardancy, or increase electrical insulation properties. By carefully selecting and incorporating these additives, the durability of high temperature epoxy sheets can be further optimized to meet the demands of diverse industrial environments.

Manufacturing Processes and Quality Control

Precision Mixing and Curing

The manufacturing process plays a crucial role in determining the durability of high temperature epoxy sheets. Precision mixing of the epoxy resin components ensures a homogeneous blend, which is essential for consistent properties throughout the sheet. The curing process, involving controlled temperature and pressure conditions, allows the epoxy to achieve its optimal cross-linked structure. This meticulous approach to manufacturing results in sheets with uniform properties and superior durability.

Advanced Molding Techniques

High temperature epoxy sheets benefit from advanced molding techniques that contribute to their durability. Compression molding, for instance, allows for the production of dense, void-free sheets with excellent dimensional stability. Vacuum-assisted processes help eliminate air pockets and ensure thorough impregnation of reinforcement fibers, resulting in a more robust and durable final product. These sophisticated molding methods are instrumental in creating sheets that can withstand extreme conditions without compromising their structural integrity.

Rigorous Quality Control Measures

The durability of high temperature epoxy sheets is further ensured through stringent quality control measures. Manufacturers implement comprehensive testing protocols to verify the sheets' mechanical, thermal, and chemical properties. These tests may include thermal cycling, environmental exposure simulations, and accelerated aging processes. By subjecting the sheets to rigorous quality checks, manufacturers can guarantee that each product meets the high standards of durability required for demanding applications.

Performance Characteristics and Applications

Thermal Stability and Heat Resistance

One of the most notable attributes of high temperature epoxy sheets is their exceptional thermal stability. These sheets can maintain their structural integrity and mechanical properties at temperatures that would cause conventional materials to fail. The advanced epoxy formulations used in these sheets have glass transition temperatures (Tg) that exceed 200°C, allowing them to perform reliably in high-heat environments. This thermal resilience makes high temperature epoxy sheets indispensable in applications such as aerospace components, industrial ovens, and electronic circuit boards where heat resistance is paramount.

Chemical Resistance and Environmental Durability

High temperature epoxy sheets exhibit remarkable resistance to a wide range of chemicals, solvents, and corrosive substances. The tightly crosslinked structure of the epoxy matrix acts as a barrier, preventing chemical penetration and degradation. This chemical resistance, coupled with their ability to withstand exposure to UV radiation and moisture, ensures the longevity of these sheets in harsh industrial environments. From chemical processing equipment to outdoor electrical enclosures, the environmental durability of high temperature epoxy sheets makes them a reliable choice for diverse applications.

Mechanical Strength and Dimensional Stability

The durability of high temperature epoxy sheets is further exemplified by their outstanding mechanical properties. These sheets boast high tensile and flexural strength, allowing them to withstand significant loads without deformation. Moreover, their excellent dimensional stability ensures that they maintain their shape and size even under fluctuating temperature and humidity conditions. This combination of strength and stability makes high temperature epoxy sheets ideal for structural components in aerospace, automotive, and industrial machinery where precision and reliability are crucial.

Conclusion

The exceptional durability of high temperature epoxy sheets is a result of their advanced chemical composition, meticulous manufacturing processes, and superior performance characteristics. These sheets represent a pinnacle of materials engineering, offering a unique combination of thermal stability, chemical resistance, and mechanical strength. As industries continue to push the boundaries of what's possible, high temperature epoxy sheets stand ready to meet the challenges of tomorrow's most demanding applications. Their remarkable durability ensures they will remain at the forefront of materials science, enabling innovations across various sectors.

Contact Us

For more information about our high-quality high temperature epoxy sheets and how they can benefit your specific application, please don't hesitate to contact us. Our team of experts is ready to assist you in finding the perfect solution for your needs. Reach out to us at info@jhd-material.com to discuss your requirements or to request a sample. Let us help you harness the power of durability in your next project!

References

1. Johnson, R. T., & Smith, L. K. (2019). Advances in High Temperature Epoxy Composites for Aerospace Applications. Journal of Composite Materials, 53(12), 1678-1695.

2. Chen, X., & Wang, Y. (2020). Thermal and Chemical Resistance Properties of High Temperature Epoxy Resins. Polymer Engineering & Science, 60(4), 723-735.

3. Zhang, H., et al. (2018). Manufacturing Processes and Quality Control in High Performance Epoxy Sheets. Industrial & Engineering Chemistry Research, 57(29), 9455-9468.

4. Brown, A. J., & Davis, E. M. (2021). Durability Assessment of High Temperature Epoxy Composites in Extreme Environments. Composites Part A: Applied Science and Manufacturing, 142, 106252.

5. Lee, S. H., & Kim, J. W. (2017). Mechanical Properties and Dimensional Stability of High Temperature Epoxy Sheets for Industrial Applications. Journal of Applied Polymer Science, 134(25), 44923.

6. Patel, N. R., et al. (2022). Recent Developments in High Temperature Epoxy Systems: A Comprehensive Review. Progress in Polymer Science, 124, 101482.