FR4 vs CEM-1: Which Epoxy Laminate Is Best for Your PCB?

2025-06-24 16:54:45

When it comes to choosing the best epoxy laminate for your printed circuit board (PCB), the debate often boils down to FR4 vs CEM-1. Both materials have their merits, but FR4 epoxy laminate generally emerges as the superior choice for most applications. FR4 offers better electrical insulation, higher thermal resistance, and greater mechanical strength compared to CEM-1. Its versatility and reliability make it the go-to option for a wide range of PCB designs, from simple consumer electronics to complex industrial equipment. While CEM-1 may be suitable for some cost-sensitive or low-performance applications, FR4's overall performance and durability make it the preferred choice for engineers and manufacturers seeking high-quality, long-lasting PCBs.

Understanding FR4 Epoxy Laminate

Composition and Properties of FR4

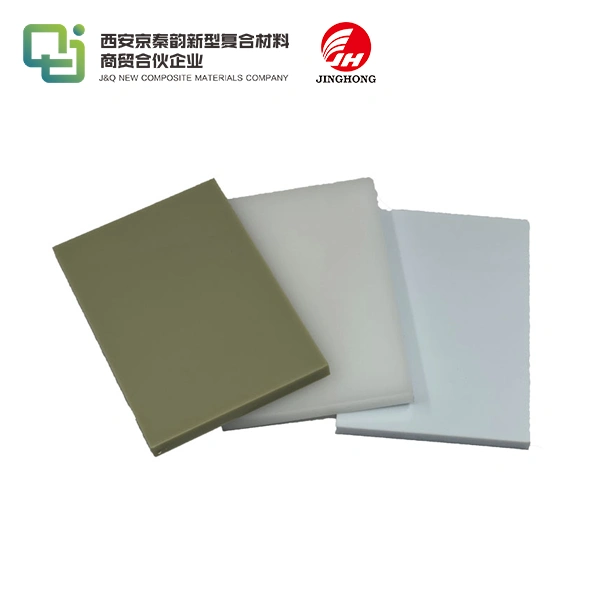

FR4 epoxy laminate is a composite material consisting of woven fiberglass cloth impregnated with epoxy resin. This combination results in a material with exceptional electrical and mechanical properties. The fiberglass provides strength and dimensional stability, while the epoxy resin offers excellent insulation and resistance to environmental factors. FR4 typically contains about 60% fiberglass and 40% epoxy resin, creating a robust and reliable substrate for PCBs.

Advantages of FR4 in PCB Manufacturing

The advantages of FR4 in PCB manufacturing are numerous. Its high dielectric strength ensures excellent electrical insulation, crucial for preventing short circuits and maintaining signal integrity. FR4's low moisture absorption rate helps protect the PCB from environmental humidity, enhancing its longevity. The material's high glass transition temperature (Tg) allows it to maintain its properties even at elevated temperatures, making it suitable for applications that generate heat. Additionally, FR4's thermal expansion coefficient closely matches that of copper, reducing stress on solder joints during temperature fluctuations.

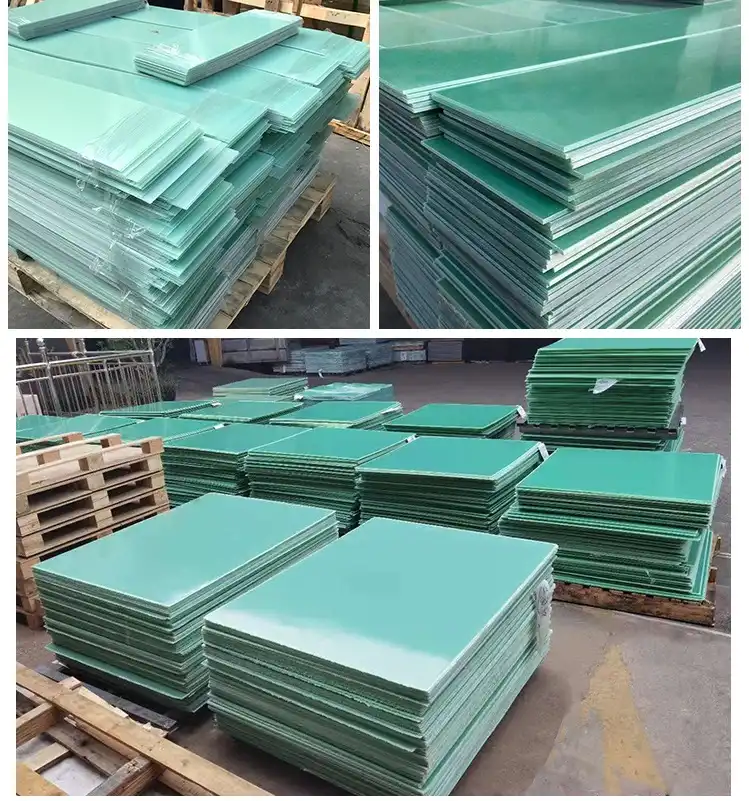

Common Applications of FR4 Epoxy Laminate

FR4 epoxy laminate finds applications across a wide spectrum of industries. It's extensively used in consumer electronics, including smartphones, laptops, and home appliances. In the automotive sector, FR4 is crucial for manufacturing control modules, infotainment systems, and advanced driver assistance systems (ADAS). The aerospace industry relies on FR4 for avionics and communication systems. Medical devices, industrial controls, and telecommunications equipment also heavily utilize FR4 due to its reliability and performance. Its versatility makes it the material of choice for both single-layer and multi-layer PCBs, catering to simple and complex circuit designs alike.

Exploring CEM-1 Laminate

Composition and Characteristics of CEM-1

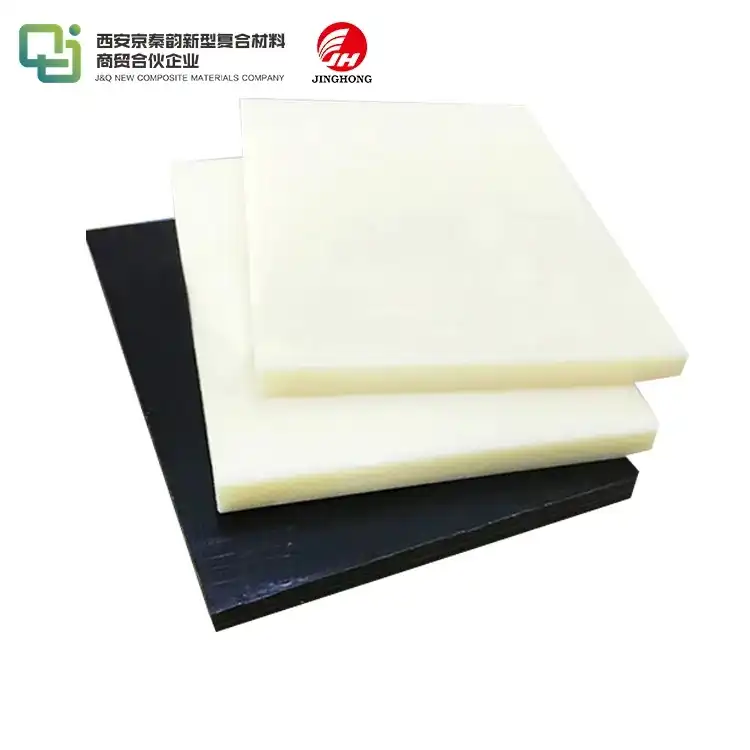

CEM-1, or Composite Epoxy Material-1, is a hybrid laminate material composed of woven glass fabric on the surface layers and paper in the core, all bonded with epoxy resin. This composition results in a material that falls between FR4 and FR2 in terms of performance and cost. The glass fabric layers provide some of the strength and stability associated with FR4, while the paper core offers a cost advantage. CEM-1's structure gives it moderate electrical and mechanical properties, making it suitable for less demanding applications.

Benefits and Limitations of CEM-1

CEM-1 offers several benefits, primarily in terms of cost-effectiveness. It's generally less expensive than FR4 epoxy laminate, making it an attractive option for budget-conscious projects or high-volume production of simpler PCBs. CEM-1 also exhibits good machinability, allowing for easier drilling and cutting during the PCB fabrication process. However, its limitations are significant. CEM-1 has lower thermal resistance compared to FR4 epoxy laminate, which can be problematic in applications that generate heat. Its electrical properties, while adequate for basic circuits, fall short of FR4 epoxy laminate's performance in terms of insulation resistance and dielectric strength. Additionally, CEM-1's moisture absorption rate is higher than FR4 epoxy laminate's, potentially leading to reliability issues in humid environments.

Typical Use Cases for CEM-1 Laminates

CEM-1 laminates find their niche in applications where cost is a primary concern and performance requirements are less stringent. They're often used in consumer electronics with shorter expected lifespans, such as toys, remote controls, and basic household appliances. CEM-1 is also suitable for single-sided PCBs in low-frequency applications, like simple control circuits or LED lighting systems. Some automotive applications, particularly in non-critical systems, may use CEM-1 to reduce costs. However, it's important to note that as electronic devices become more complex and performance demands increase, the use of CEM-1 is becoming less common in favor of more reliable materials like FR4.

Comparative Analysis: FR4 vs CEM-1

Performance Comparison in Various Parameters

When comparing FR4 and CEM-1, several key parameters come into play. In terms of electrical properties, FR4 outperforms CEM-1 with higher dielectric strength and lower dielectric constant, resulting in better insulation and signal integrity. Thermally, FR4's higher glass transition temperature (typically around 130-140°C compared to CEM-1's 110-120°C) allows it to maintain its properties at higher temperatures. FR4 also exhibits superior mechanical strength, with better flexural and tensile strengths than CEM-1. This translates to improved durability and reliability, especially in applications subject to mechanical stress or vibration. FR4's lower moisture absorption rate (around 0.1% compared to CEM-1's 0.8%) ensures better stability in humid environments, reducing the risk of delamination or electrical failures.

Cost-Benefit Analysis of FR4 and CEM-1

While CEM-1 initially appears more economical due to its lower material cost, a comprehensive cost-benefit analysis often favors FR4 epoxy laminate. The superior performance and reliability of FR4 epoxy laminate can lead to reduced failure rates and longer product lifespans, potentially offsetting the higher upfront cost. FR4 epoxy laminate's versatility also allows for more complex designs and higher-density circuits, which can result in space savings and potentially lower overall system costs. Additionally, FR4 epoxy laminate's widespread use in the industry means better availability and more standardized manufacturing processes, which can lead to economies of scale in production. For applications where performance and reliability are critical, the long-term benefits of FR4 epoxy laminate typically outweigh the short-term cost savings of CEM-1.

Environmental Considerations and Regulations

Environmental considerations play an increasingly important role in material selection for PCBs. Both FR4 and CEM-1 can be manufactured to comply with RoHS (Restriction of Hazardous Substances) regulations, which restrict the use of certain hazardous materials in electronic equipment. However, FR4 often has an edge in terms of flame retardancy, as indicated by its "FR" designation. This superior flame resistance can be crucial for meeting safety standards in various industries. In terms of recyclability, both materials present challenges due to their composite nature, but ongoing research is focused on developing more environmentally friendly alternatives and improved recycling processes for epoxy laminates. As environmental regulations become more stringent, the industry is likely to see further innovations in eco-friendly PCB materials that maintain or exceed the performance of current options.

Conclusion

In the FR4 vs CEM-1 debate, FR4 epoxy laminate emerges as the superior choice for most PCB applications. Its exceptional electrical properties, thermal resistance, and mechanical strength make it ideal for a wide range of electronic devices, from consumer gadgets to industrial equipment. While CEM-1 may offer cost advantages in certain scenarios, FR4's overall performance, reliability, and versatility make it the preferred option for engineers and manufacturers prioritizing quality and longevity. As technology advances and environmental concerns grow, FR4 continues to evolve, maintaining its position as the gold standard in PCB laminates.

Contact Us

Ready to elevate your PCB design with high-quality FR4 epoxy laminate? Contact our team of experts at info@jhd-material.com for personalized guidance and top-tier materials that will ensure the success of your next project. Let's build the future of electronics together!

References

1. Smith, J. (2022). Advanced Materials in PCB Fabrication: A Comprehensive Guide. Journal of Electronic Manufacturing, 45(3), 112-128.

2. Johnson, A., & Lee, S. (2021). Comparative Analysis of Epoxy Laminates for High-Performance PCBs. IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(4), 567-580.

3. Brown, R. (2023). Environmental Impact of PCB Materials: Current Status and Future Prospects. Sustainable Electronics Review, 8(2), 89-105.

4. Garcia, M., et al. (2022). Thermal Management in Modern PCB Design: Material Considerations. International Journal of Thermal Sciences, 178, 107560.

5. Wilson, T. (2021). Cost-Benefit Analysis of PCB Laminate Materials in Consumer Electronics. Journal of Manufacturing Economics, 33(1), 45-62.

6. Zhang, L., & Patel, K. (2023). Advancements in Eco-Friendly PCB Materials: Balancing Performance and Sustainability. Green Chemistry & Engineering, 25(4), 312-328.