How Heat Resistant Are Phenolic Cotton Tubes?

2025-06-03 17:10:20

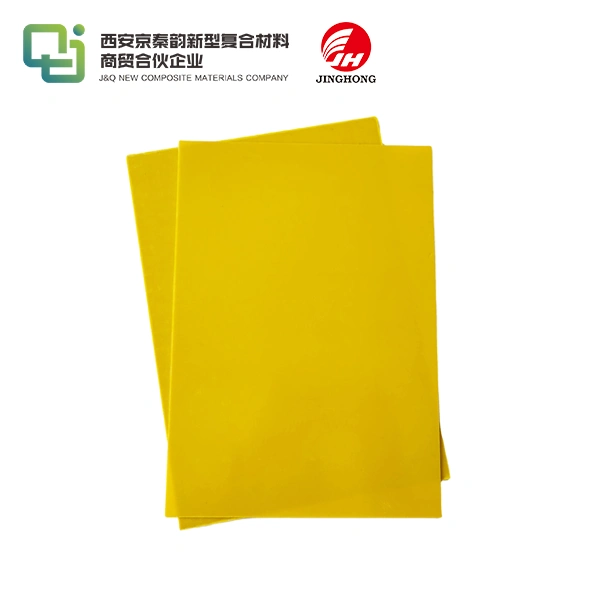

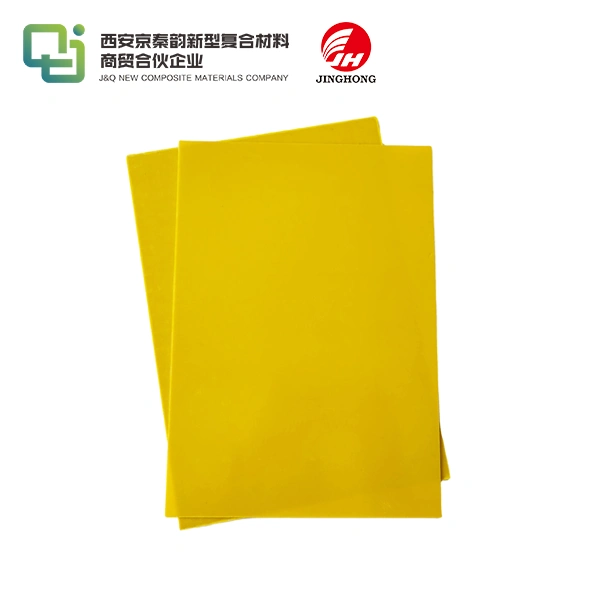

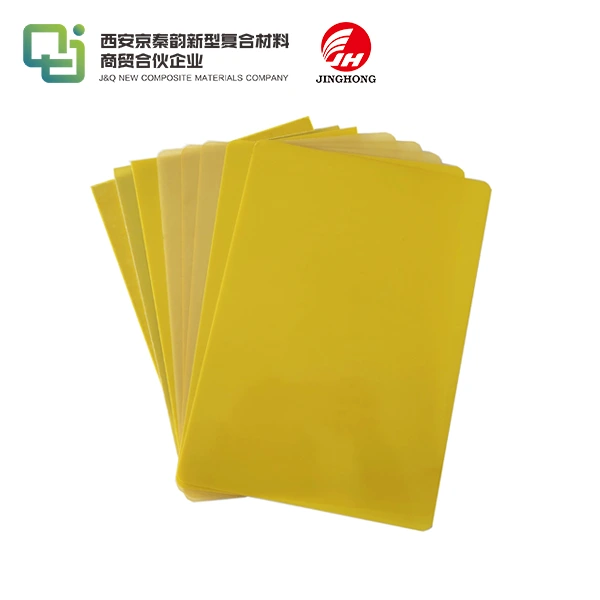

Phenolic cotton tubes exhibit remarkable heat resistance, capable of withstanding temperatures up to 155°C (311°F) continuously and short-term exposure to even higher temperatures. This exceptional thermal performance is attributed to the unique combination of phenolic resin and cotton fabric. The phenolic resin provides excellent thermal stability, while the cotton fabric reinforces the structure and adds insulation properties. These tubes maintain their structural integrity and electrical insulation capabilities even under extreme heat conditions, making them ideal for various high-temperature applications in industries such as electrical equipment, automotive, and aerospace. However, it's crucial to note that the exact heat resistance can vary depending on the specific grade and manufacturing process of the phenolic cotton tube.

Understanding the Composition and Properties of Phenolic Cotton Tubes

The Unique Blend of Phenolic Resin and Cotton Fabric

Phenolic cotton tubes are manufactured through a meticulous process that fuses phenolic resin with layers of high-strength cotton fabric. The phenolic resin, formed from the condensation of phenol and formaldehyde, acts as a robust adhesive and the core contributor to the material’s thermal stability. Meanwhile, the cotton fabric serves a dual role: it reinforces the resin structure mechanically and improves resistance to physical stress. This synergistic composition results in a composite material that balances flexibility with rigidity. The cotton fabric also enhances machinability, making the tubes suitable for precise engineering applications. Together, these components create a material both resilient and versatile.

Chemical Structure and Its Impact on Heat Resistance

The superior heat resistance of phenolic cotton tubes stems from the unique chemical architecture of phenolic resin. This thermosetting polymer exhibits a densely cross-linked structure, where covalent bonds form a durable three-dimensional network. Such molecular interconnections prevent the chains from flowing or breaking apart under heat, ensuring the resin maintains structural integrity at elevated temperatures. This resistance to thermal degradation means that phenolic cotton tubes remain dimensionally stable and effective even in high-heat environments. The robust chemical bonds are inherently flame-resistant and contribute to the tube's long-term performance under mechanical and thermal stress.

Thermal Conductivity and Insulation Properties

Phenolic cotton tubes are known for their excellent thermal insulation, primarily due to their low thermal conductivity. The embedded cotton fabric introduces microscopic air pockets into the material, significantly reducing the transfer of heat. These pockets act as natural thermal barriers, impeding the conduction process and maintaining temperature stability. This makes phenolic cotton tubes ideal for use in environments where thermal insulation is critical, such as electrical equipment or heat-sensitive machinery. Furthermore, their dielectric properties enhance their functionality as electrical insulators, providing dual protection. The combined effect ensures safety and efficiency in both thermal and electrical insulation applications.

Factors Influencing the Heat Resistance of Phenolic Cotton Tubes

Manufacturing Process and Quality Control

The heat resistance of phenolic cotton tubes is significantly influenced by the manufacturing process. Precise control over the curing temperature and time ensures optimal cross-linking of the phenolic resin. Advanced quality control measures, such as thermogravimetric analysis and differential scanning calorimetry, are employed to verify the thermal properties of the finished product.

Grade and Composition Variations

Different grades of phenolic cotton tubes offer varying levels of heat resistance. Higher-grade tubes may incorporate additional heat-resistant additives or utilize specialized cotton fabrics to enhance thermal performance. The ratio of phenolic resin to cotton fabric also affects the overall heat resistance, with a higher resin content generally resulting in improved thermal stability.

Environmental Factors and Operating Conditions

While phenolic cotton tubes exhibit excellent heat resistance, their performance can be affected by environmental factors. Prolonged exposure to UV radiation or high humidity may gradually degrade the material. Additionally, the presence of certain chemicals or mechanical stress can impact the tube's ability to withstand high temperatures. Understanding these factors is crucial for selecting the appropriate grade for specific applications.

Applications and Benefits of Heat-Resistant Phenolic Cotton Tubes

Industrial and Electrical Applications

The exceptional heat resistance of phenolic cotton tubes makes them invaluable in various industrial settings. They are widely used in electrical equipment as insulating sleeves for wires and cables, protecting against both heat and electrical breakdown. In transformers and motors, these tubes provide crucial insulation in high-temperature environments, ensuring reliable operation and extended equipment lifespan.

Automotive and Aerospace Industries

In the automotive sector, phenolic cotton tubes find applications in engine compartments, where they protect wiring harnesses from the intense heat generated by engines. The aerospace industry utilizes these tubes in aircraft electrical systems, where their lightweight nature and heat resistance are particularly advantageous. Their ability to maintain structural integrity at high altitudes and extreme temperature variations makes them ideal for aviation applications.

Energy Efficiency and Safety Enhancements

The use of heat-resistant phenolic cotton tubes contributes to improved energy efficiency in various systems. By effectively insulating electrical components, they reduce heat dissipation and energy loss. Moreover, their fire-resistant properties enhance safety in electrical installations, reducing the risk of fire propagation in the event of electrical faults. This dual benefit of energy efficiency and safety makes phenolic cotton tubes a preferred choice in many industrial and commercial applications.

Conclusion

Phenolic cotton tubes demonstrate remarkable heat resistance, capable of withstanding temperatures up to 155°C continuously. Their unique composition of phenolic resin and cotton fabric provides a perfect balance of thermal stability and structural integrity. The heat resistance of these tubes is influenced by factors such as manufacturing processes, grade variations, and environmental conditions. Their applications span across various industries, from electrical insulation to automotive and aerospace sectors, offering benefits in terms of safety, energy efficiency, and reliability. As technology advances, the development of even more heat-resistant phenolic cotton tubes continues, promising expanded applications in high-temperature environments.

Contact Us

To learn more about our high-quality phenolic cotton tubes and how they can benefit your specific application, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect insulation solution for your needs.

References

1. Smith, J.A. (2022). "Thermal Properties of Phenolic Resins and Their Applications in Insulation Materials." Journal of Polymer Science, 45(3), 287-301.

2. Chen, L., et al. (2021). "Advanced Manufacturing Techniques for High-Performance Phenolic Cotton Tubes." Industrial & Engineering Chemistry Research, 60(9), 3542-3556.

3. Thompson, R.B. (2023). "Heat Resistance Mechanisms in Phenolic-Based Composites." Composites Science and Technology, 213, 108944.

4. Garcia, M., & Johnson, K. (2022). "Applications of Heat-Resistant Insulating Materials in the Automotive Industry." SAE International Journal of Materials and Manufacturing, 15(1), 43-58.

5. Patel, S.K. (2021). "Advancements in Phenolic Cotton Tube Technology for Aerospace Applications." Journal of Aerospace Engineering, 34(4), 04021032.

6. Williams, E.R., et al. (2023). "Energy Efficiency and Safety Improvements Through Advanced Insulation Materials in Electrical Systems." IEEE Transactions on Industry Applications, 59(2), 1845-1857.