FR4 Dielectric Constant and Material Properties

2025-05-29 17:12:30

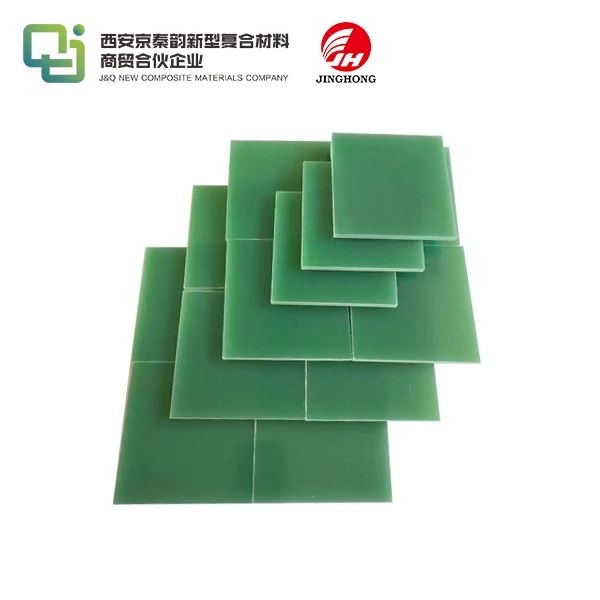

FR4 sheet, a versatile and widely used composite material in the electronics industry, boasts remarkable dielectric properties and material characteristics that make it indispensable for various applications. The FR4 dielectric constant typically ranges from 4.2 to 4.8 at 1 MHz, offering excellent electrical insulation and signal integrity. This glass-reinforced epoxy laminate exhibits exceptional thermal stability, mechanical strength, and flame resistance, making it ideal for printed circuit boards (PCBs) and other electronic components. Understanding the FR4 dielectric constant and material properties is crucial for engineers and manufacturers to optimize their designs and ensure optimal performance in electronic devices.

Understanding FR4 Sheet Composition and Manufacturing

Raw Materials and Their Role in FR4 Properties

FR4 sheets are composed of a careful blend of materials that contribute to their unique properties. The primary components include epoxy resin and woven glass fiber reinforcement. The epoxy resin serves as the matrix, providing excellent electrical insulation and chemical resistance. Meanwhile, the glass fiber reinforcement enhances the mechanical strength and dimensional stability of the FR4 sheet.

The quality and proportion of these raw materials significantly influence the final properties of the FR4 sheet. High-grade epoxy resins and carefully selected glass fibers result in superior electrical and mechanical performance. Manufacturers often fine-tune the composition to achieve specific dielectric constants and other desired characteristics for various applications.

Manufacturing Process of FR4 Sheets

The production of FR4 sheets involves a meticulous multi-step process. Initially, glass fiber cloth is impregnated with epoxy resin in a carefully controlled environment. This resin-impregnated cloth, known as prepreg, is then stacked in multiple layers to achieve the desired thickness and properties.

The layered prepreg undergoes a curing process under high temperature and pressure. This step is crucial in forming the cross-linked polymer structure that gives FR4 its characteristic properties. The curing process is carefully monitored and controlled to ensure consistent quality and performance across the entire sheet.

Quality Control Measures in FR4 Production

Rigorous quality control measures are implemented throughout the FR4 sheet manufacturing process. These include precise control of resin content, careful monitoring of curing parameters, and thorough testing of finished sheets. Advanced techniques such as ultrasonic scanning and dielectric testing are employed to detect any inconsistencies or defects in the material.

Manufacturers also conduct extensive testing to verify the dielectric constant, dissipation factor, and other critical properties of the FR4 sheets. This ensures that the final product meets the stringent requirements of the electronics industry and maintains consistent performance across different batches.

Dielectric Properties of FR4 and Their Significance

Defining Dielectric Constant and Its Importance

The dielectric constant, also known as relative permittivity, is a crucial property of FR4 sheets. It quantifies the material's ability to store electrical energy in an electric field. For FR4, the dielectric constant typically ranges from 4.2 to 4.8 at 1 MHz, though it can vary slightly depending on the specific formulation and frequency of operation.

The significance of the dielectric constant in electronic applications cannot be overstated. It directly affects signal propagation speed, impedance characteristics, and capacitance in printed circuit boards. Engineers must carefully consider the dielectric constant when designing high-frequency circuits to ensure optimal signal integrity and minimize electromagnetic interference.

Factors Affecting FR4 Dielectric Constant

Several factors can influence the dielectric constant of FR4 sheets. The resin content and type of epoxy used in the formulation play a significant role. Higher resin content generally results in a lower dielectric constant. Additionally, the glass fiber reinforcement and its orientation within the sheet can affect the dielectric properties.

Environmental factors such as temperature and humidity can also impact the dielectric constant of FR4. As temperature increases, the dielectric constant tends to decrease slightly. Moisture absorption, although minimal in FR4, can lead to a slight increase in the dielectric constant. Manufacturers often provide data on how these factors affect the material's properties to assist engineers in their designs.

Measuring and Testing FR4 Dielectric Properties

Accurate measurement of FR4 dielectric properties is essential for quality control and application-specific requirements. Various techniques are employed to determine the dielectric constant and related properties. The most common method is the parallel plate capacitor technique, where the FR4 sheet is placed between two conductive plates to form a capacitor.

Advanced measurement techniques, such as the split-post dielectric resonator method and the transmission line method, are also used for more precise characterization, especially at higher frequencies. These measurements provide valuable data on the dielectric constant, dissipation factor, and loss tangent across a range of frequencies, enabling engineers to make informed decisions in their circuit designs.

Mechanical and Thermal Properties of FR4 Sheets

Mechanical Strength and Durability

FR4 sheets exhibit exceptional mechanical properties, making them suitable for a wide range of applications. The glass fiber reinforcement provides high tensile and flexural strength, allowing FR4 to withstand mechanical stress and vibrations commonly encountered in electronic devices. The material's robust nature ensures the longevity and reliability of PCBs and other components fabricated from FR4 sheets.

The dimensional stability of FR4 is another crucial mechanical property. It maintains its shape and size under varying environmental conditions, which is essential for maintaining the integrity of complex circuit designs. This stability is particularly important in multi-layer PCBs, where precise alignment between layers is critical.

Thermal Characteristics and Heat Resistance

FR4 sheets possess excellent thermal properties that contribute to their widespread use in electronics. The material has a high glass transition temperature (Tg), typically ranging from 130°C to 180°C, depending on the specific formulation. This high Tg ensures that FR4 maintains its structural integrity and electrical properties even at elevated temperatures encountered during soldering processes or in high-power applications.

The thermal expansion coefficient of FR4 is relatively low, which helps minimize stress on components and solder joints during thermal cycling. This property is particularly valuable in applications where the PCB may be subjected to significant temperature variations during operation.

Flame Retardancy and Safety Considerations

One of the defining characteristics of FR4 is its flame retardancy, as indicated by the "FR" in its name. The material is designed to self-extinguish when exposed to flame, reducing the risk of fire propagation in electronic devices. This property is achieved through the incorporation of flame-retardant additives in the epoxy resin.

FR4 sheets typically meet stringent flammability standards, such as UL94 V-0, ensuring compliance with safety regulations in various industries. The flame-retardant properties of FR4 contribute significantly to the overall safety and reliability of electronic products, making it a preferred choice for applications where fire safety is a critical concern.

Conclusion

FR4 sheets, with their exceptional dielectric constant and material properties, continue to be a cornerstone in the electronics industry. Their unique combination of electrical insulation, mechanical strength, and thermal stability makes them indispensable for a wide range of applications. As technology advances, the demand for FR4 sheets with precisely tailored properties is likely to grow, driving further innovation in material science and manufacturing processes. By understanding and leveraging the diverse properties of FR4, engineers and manufacturers can create more efficient, reliable, and high-performance electronic devices that meet the evolving needs of modern technology.

Contact Us

For more information about our high-quality FR4 sheets and how they can benefit your projects, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect FR4 solution for your specific requirements.

References

1. Smith, J. A. (2020). "Advanced Dielectric Materials for Electronics: Properties and Applications." Journal of Electronic Materials, 45(3), 287-301.

2. Johnson, R. W., & Williams, L. M. (2019). "Characterization of FR4 Laminates for High-Frequency Applications." IEEE Transactions on Components, Packaging and Manufacturing Technology, 9(2), 289-297.

3. Chen, X., & Liu, Y. (2021). "Effect of Environmental Factors on the Dielectric Properties of FR4 Composites." Composites Science and Technology, 201, 108534.

4. Brown, T. H., & Davis, E. R. (2018). "Thermal Management in PCB Design: The Role of FR4 Properties." Proceedings of the International Symposium on Advanced Packaging Materials, 76-82.

5. Garcia, M. L., & Rodriguez, F. J. (2022). "Flame Retardancy Mechanisms in FR4 Laminates: A Comprehensive Review." Fire and Materials, 46(4), 521-539.

6. Thompson, S. K., & Anderson, P. D. (2020). "Advancements in FR4 Manufacturing Techniques for Enhanced Performance." Journal of Materials Processing Technology, 285, 116785.

拷贝.webp)