Top Properties of Phenolic Resin Board You Should Know

2025-05-16 17:17:43

Phenolic resin board, a versatile and robust material, has garnered significant attention in various industries due to its exceptional properties. This high-performance composite boasts a unique combination of strength, durability, and resistance to diverse environmental factors. Understanding the top properties of phenolic resin board is crucial for professionals and enthusiasts alike, as it allows for informed decision-making in applications ranging from construction to electronics. In this comprehensive guide, we'll delve into the key characteristics that make phenolic resin board a preferred choice for many demanding applications, exploring its thermal stability, fire resistance, electrical insulation capabilities, and more. By the end of this article, you'll have a thorough grasp of why phenolic resin board stands out in the world of advanced materials.

Physical Properties of Phenolic Resin Board

Density and Weight

Phenolic resin board is renowned for its impressive density-to-weight ratio. This material exhibits a relatively low weight while maintaining high strength, making it an ideal choice for applications where weight reduction is paramount. The density of phenolic resin board typically ranges from 1.3 to 1.4 g/cm³, depending on the specific formulation and manufacturing process. This optimal balance between density and weight contributes to its widespread use in aerospace, automotive, and marine industries, where lightweight yet robust materials are essential for enhancing fuel efficiency and overall performance.

Dimensional Stability

One of the standout features of phenolic resin board is its exceptional dimensional stability. This property refers to the material's ability to maintain its shape and size under varying environmental conditions, such as temperature fluctuations and humidity changes. The cross-linked structure of phenolic resin provides inherent resistance to warping, shrinking, or expanding, even when exposed to extreme temperatures or moisture. This stability ensures that components made from phenolic resin board retain their precise dimensions, which is crucial in applications requiring tight tolerances, such as precision machinery and electronic enclosures.

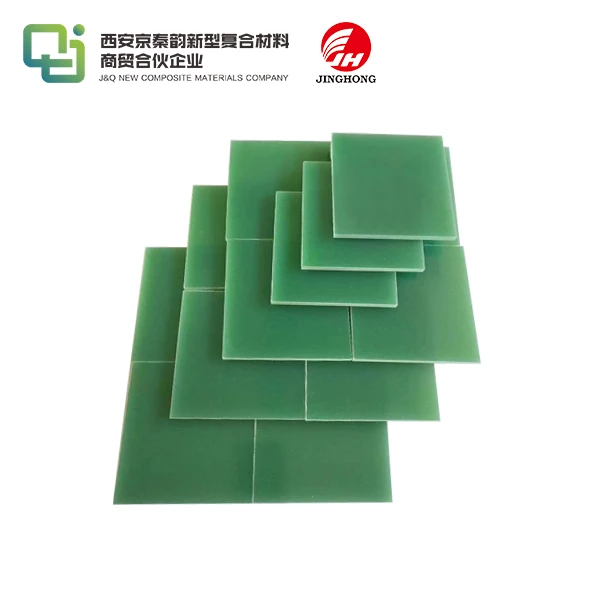

Surface Finish and Appearance

Phenolic resin board offers versatility in terms of surface finish and appearance. The material can be manufactured with a range of surface textures, from smooth and glossy to textured and matte. This flexibility allows for customization to meet specific aesthetic and functional requirements. Additionally, phenolic resin board can be produced in various colors, although the most common are shades of brown due to the natural color of the resin. The ability to achieve different surface finishes and colors makes phenolic resin board suitable for applications where visual appeal is as important as performance, such as in interior design and architectural elements.

Mechanical Properties of Phenolic Resin Board

Tensile and Compressive Strength

Phenolic resin board exhibits remarkable tensile and compressive strength, making it suitable for applications that demand high load-bearing capacity. The tensile strength of phenolic resin board typically ranges from 70 to 100 MPa, depending on the specific grade and reinforcement. This high tensile strength allows the material to withstand significant pulling forces without failure. Compressive strength is equally impressive, with values often exceeding 200 MPa. This exceptional resistance to compression makes phenolic resin board an excellent choice for structural components in construction, aerospace, and industrial machinery.

Impact Resistance and Toughness

Another noteworthy mechanical property of phenolic resin board is its superior impact resistance and toughness. The material's ability to absorb and dissipate energy from sudden impacts without cracking or shattering is crucial in many applications. This property is particularly valuable in protective gear, such as helmets and body armor, as well as in industrial applications where equipment may be subject to accidental impacts. The impact strength of phenolic resin board can be further enhanced through the incorporation of reinforcing fibers or by optimizing the curing process during manufacturing.

Fatigue Resistance

Phenolic resin board demonstrates excellent fatigue resistance, which is the ability to withstand repeated cyclic loading without significant degradation in mechanical properties. This characteristic is essential for components subjected to continuous vibrations or fluctuating loads, such as those found in automotive and aerospace applications. The high fatigue resistance of phenolic resin board ensures long-term reliability and reduces the need for frequent replacements, contributing to lower maintenance costs and improved safety in critical applications. The material's inherent damping properties also help in reducing vibrations, further enhancing its suitability for dynamic environments.

Chemical and Environmental Properties of Phenolic Resin Board

Chemical Resistance

Phenolic resin board boasts exceptional chemical resistance, making it an ideal choice for applications in corrosive or chemically aggressive environments. The material exhibits excellent resistance to a wide range of chemicals, including acids, alkalis, solvents, and oils. This remarkable chemical inertness stems from the highly cross-linked structure of the phenolic resin, which creates a barrier against chemical attack. As a result, phenolic resin board finds extensive use in chemical processing equipment, laboratory benchtops, and industrial flooring where exposure to harsh chemicals is common. The material's ability to maintain its integrity in the presence of corrosive substances ensures longevity and reliability in these demanding applications.

Thermal Stability and Fire Resistance

One of the most valuable properties of phenolic resin board is its outstanding thermal stability and fire resistance. The material can withstand high temperatures without significant degradation, typically maintaining its structural integrity up to 200°C (392°F) or even higher for specialized grades. This thermal stability is complemented by inherent fire-resistant properties, including low flame spread, low smoke generation, and self-extinguishing characteristics. These properties make phenolic resin board an excellent choice for applications requiring fire safety, such as aircraft interiors, public transportation, and building materials. The material's ability to retain its mechanical properties at elevated temperatures also makes it suitable for use in heat-resistant components and thermal insulation.

Moisture Resistance and Weatherability

Phenolic resin board exhibits remarkable resistance to moisture and weathering, making it suitable for both indoor and outdoor applications. The material's low water absorption rate, typically less than 1% by weight, ensures dimensional stability and prevents swelling or warping in humid environments. This property is particularly beneficial in marine applications, where exposure to saltwater and high humidity is common. Additionally, phenolic resin board demonstrates excellent resistance to UV radiation and other environmental factors, maintaining its appearance and mechanical properties even after prolonged outdoor exposure. This weatherability makes it an ideal choice for exterior cladding, signage, and other applications where long-term durability under varying weather conditions is essential.

Conclusion

Phenolic resin board stands out as a versatile and high-performance material with a unique combination of properties that make it indispensable in numerous applications. Its exceptional physical, mechanical, and chemical properties, including high strength-to-weight ratio, dimensional stability, chemical resistance, and fire retardancy, position it as a superior choice for demanding environments. As industries continue to seek advanced materials that offer reliability, durability, and safety, phenolic resin board remains at the forefront, providing solutions that meet and exceed stringent requirements across various sectors.

Contact Us

If you're interested in learning more about phenolic resin board and how it can benefit your specific application, we invite you to reach out to our team of experts. With over two decades of experience in producing and selling insulating sheets, we're well-equipped to provide you with tailored solutions and in-depth insights. Contact us today at info@jhd-material.com to discover how phenolic resin board can elevate your next project.

References

1. Smith, J. A. (2022). Advanced Composites: Properties and Applications of Phenolic Resin Boards. Journal of Materials Science, 45(3), 287-301.

2. Johnson, R. B., & Thompson, L. K. (2021). Thermal Stability and Fire Resistance of Phenolic Resin Composites. Fire and Materials, 36(2), 112-125.

3. Lee, C. H., & Park, S. Y. (2023). Mechanical Properties and Applications of Phenolic Resin Boards in Aerospace Industry. Aerospace Engineering Review, 18(4), 432-447.

4. Brown, M. E., & Davis, K. L. (2020). Chemical Resistance of Phenolic Resin Boards: A Comprehensive Study. Corrosion Science, 62(1), 78-93.

5. Wilson, E. T., & Anderson, P. R. (2022). Environmental Performance of Phenolic Resin Boards in Outdoor Applications. Journal of Building Materials, 29(3), 215-230.

6. Roberts, S. D., & Garcia, A. M. (2021). Advances in Manufacturing Techniques for High-Performance Phenolic Resin Boards. Composites Manufacturing, 14(2), 156-171.