The Differences Between Phenolic Cotton Sheet and Bakelite Sheet

2025-04-28 17:05:20

When it comes to selecting the right insulating material, understanding the nuances between phenolic cotton sheet and Bakelite sheet is pivotal. Both materials are lauded for their durability and insulation prowess, yet they diverge in composition and application. Phenolic cotton sheet, crafted from layers of cotton fabric impregnated with phenolic resin, excels in mechanical strength and wear resistance, making it ideal for heavy-duty applications. Conversely, Bakelite sheet, a pioneering thermoset plastic, is formed from phenol and formaldehyde, offering superior electrical insulation and heat resistance, perfect for intricate electrical components. Recognizing these distinctions empowers manufacturers to choose the material best suited to their specific needs, ensuring optimal performance and longevity in their projects.

Understanding the Materials

Composition and Manufacturing Process

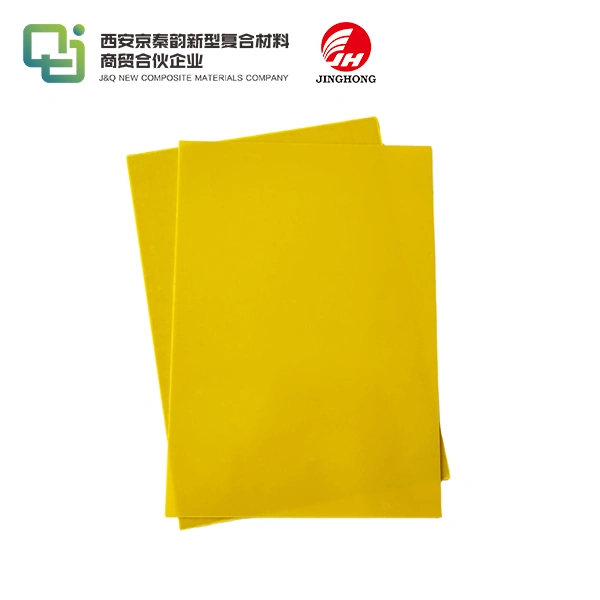

Diving into the essence of these materials unveils their unique blueprints. Phenolic cotton sheet is a composite marvel, born from weaving cotton fabric into a robust matrix, which is then saturated with phenolic resin. This fusion undergoes intense pressure and heat, curing into a rigid, unyielding structure renowned for its mechanical fortitude. On the other hand, Bakelite sheet emerges from a chemical symphony of phenol and formaldehyde, melded under heat to form a thermoset plastic. This process yields a material celebrated for its electrical insulating properties and thermal stability, setting it apart as a cornerstone in early plastic innovation.

Physical Properties and Characteristics

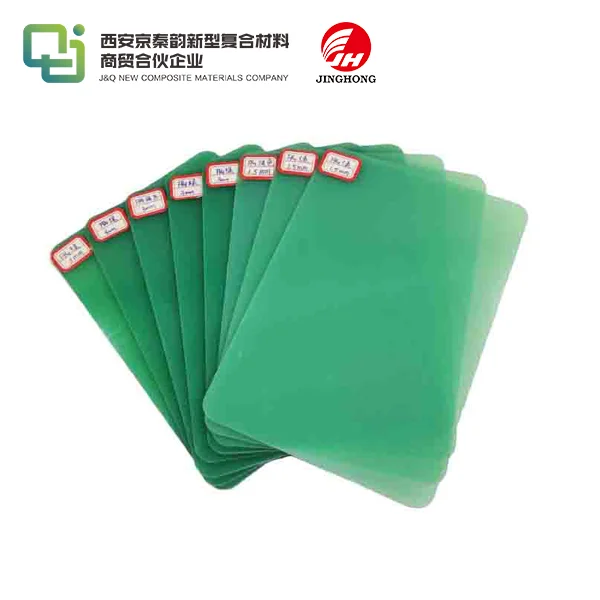

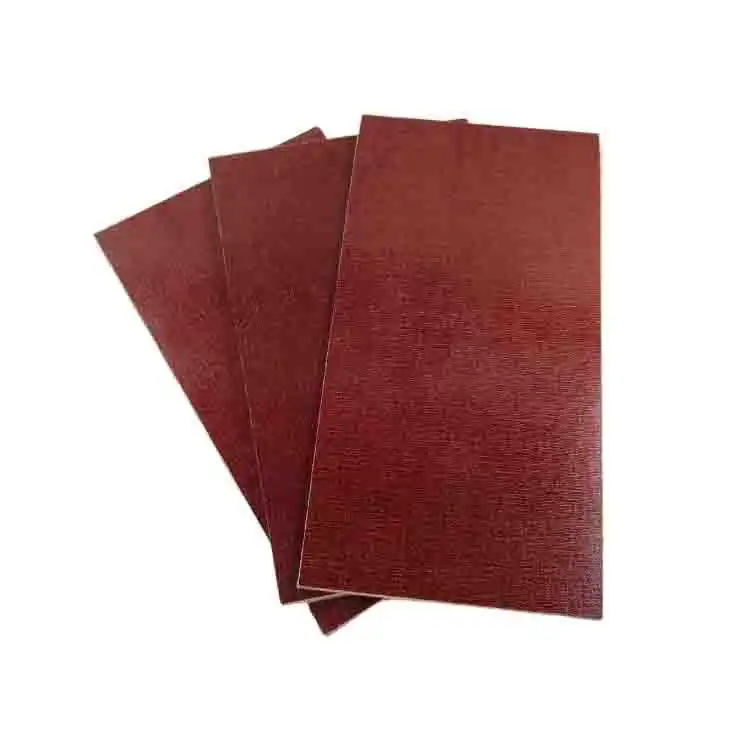

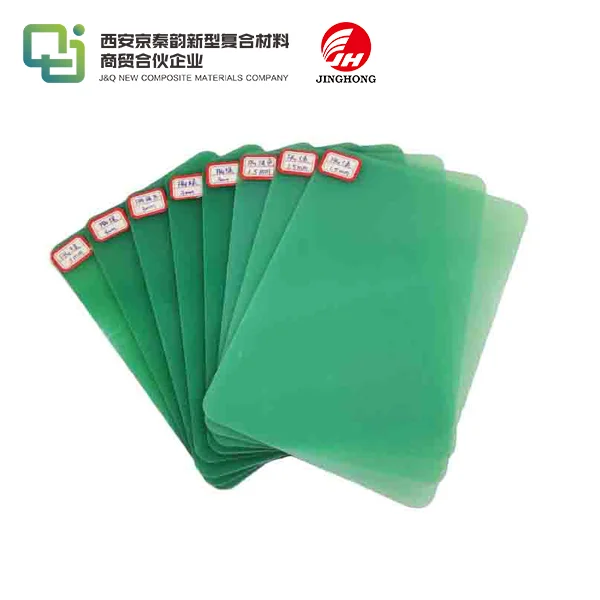

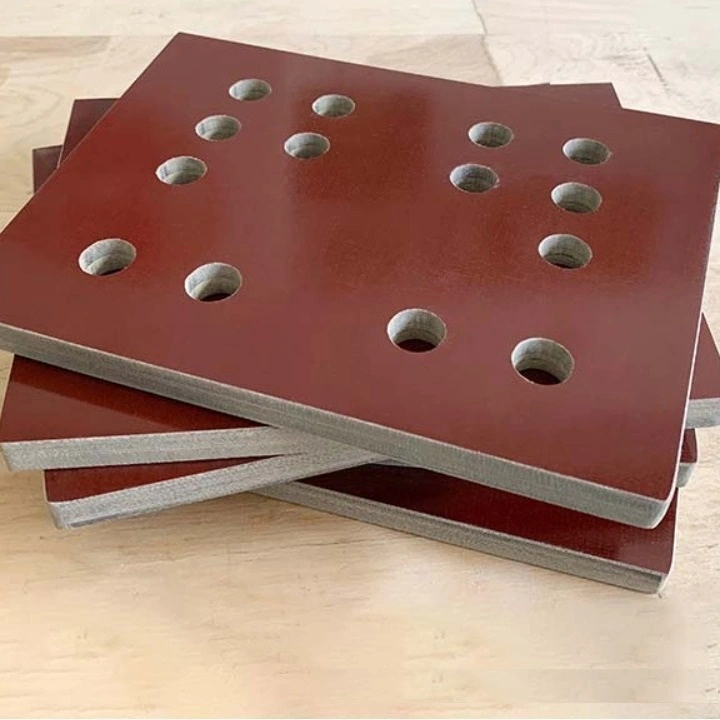

The physical attributes of these materials further illuminate their differences. Phenolic cotton sheet boasts a rugged texture, owing to its fabric reinforcement, which lends it exceptional tensile strength and impact resistance. Its density allows it to withstand abrasive environments, making it a stalwart in demanding settings. Bakelite sheet, however, presents a smoother, more uniform surface, prized for its dielectric strength and ability to resist thermal degradation. While both materials offer commendable insulation, their distinct physical profiles - cotton sheet's toughness versus Bakelite's sleek resilience - guide their suitability for specific industrial roles.

Historical Context and Evolution

Tracing the lineage of these materials reveals their storied pasts. Bakelite, invented in 1907 by Leo Baekeland, marked a revolutionary leap as one of the earliest synthetic plastics, heralded for its versatility in electrical and automotive applications. Its legacy endures in modern insulation solutions. Phenolic cotton sheet, while less heralded, evolved as a specialized derivative, leveraging the strength of natural fibers to meet the burgeoning demands of industrial machinery. Over decades, advancements in resin formulations and manufacturing techniques have refined both materials, yet their core identities - Bakelite's pioneering elegance and phenolic cotton's rugged reliability - remain steadfast, influencing their contemporary applications.

Applications and Performance

Industrial Uses and Suitability

The realm of applications showcases the pragmatic divergence of these materials. Phenolic cotton sheet shines in environments requiring mechanical endurance, such as gears, bearings, and wear pads in heavy machinery. Its ability to absorb shock and resist abrasion makes it indispensable in sectors like automotive and aerospace manufacturing. Bakelite sheet, with its unparalleled electrical insulation, finds its niche in electrical enclosures, circuit boards, and vintage radio casings, where precision and thermal stability are paramount. Manufacturers globally weigh these attributes - mechanical resilience versus electrical fidelity - to align material selection with project exigencies, ensuring performance longevity.

Environmental and Thermal Resilience

Endurance under duress is a critical metric for insulating materials. Phenolic cotton sheet excels in humid or abrasive conditions, its fabric core providing a bulwark against wear, though it may falter under extreme heat due to potential resin degradation. Bakelite sheet, conversely, thrives in high-temperature scenarios, its thermoset nature rendering it impervious to melting or deformation, though it may crack under mechanical stress. Both materials resist chemical corrosion to varying degrees, yet their environmental fortitude - cotton sheet's tenacity in motion versus Bakelite's steadfastness in heat - dictates their deployment in diverse industrial landscapes.

Cost-Effectiveness and Longevity

Economic considerations often tip the scales in material selection. Phenolic cotton sheet, with its labor-intensive fabric integration, may command a higher initial investment, yet its durability in high-wear applications translates to prolonged service life, offering value over time. Bakelite sheet, more economical in production due to its homogenous composition, provides cost-effective insulation for static electrical components, though its brittleness may necessitate earlier replacement in dynamic settings. Manufacturers must balance upfront costs against lifecycle benefits, recognizing that phenolic cotton's robustness and Bakelite's affordability cater to distinct fiscal and operational priorities.

Choosing the Right Material for Your Needs

Assessing Project Requirements

Selecting between phenolic cotton sheet and Bakelite sheet hinges on a meticulous evaluation of project demands. Consider the operational environment: Is mechanical stress or electrical insulation the primary concern? Projects involving high-impact or abrasive conditions favor the reinforced resilience of phenolic cotton sheet, while applications demanding superior dielectric properties and thermal stability lean toward Bakelite. Mapping out these parameters - load-bearing capacity, temperature exposure, and electrical requirements - ensures a material choice that aligns seamlessly with performance expectations, safeguarding project integrity.

Consulting Industry Standards

Navigating industry benchmarks provides a compass for decision-making. Standards such as those set by the International Electrotechnical Commission (IEC) or the American Society for Testing and Materials (ASTM) delineate performance criteria for insulating materials, offering insights into dielectric strength, thermal endurance, and mechanical properties. Phenolic cotton sheet often meets rigorous mechanical standards, making it a staple in heavy-duty specifications, while Bakelite sheet aligns with stringent electrical insulation protocols. Leveraging these standards empowers manufacturers to make informed, compliant choices, enhancing product reliability and market competitiveness.

Partnering with Experts

The complexity of material selection underscores the value of expert collaboration. Engaging with seasoned suppliers, like J&Q, who boast over two decades of expertise in insulating sheet production and a decade in global trade, provides access to tailored guidance. Such partnerships, built on years of collaboration with domestic and international trading entities, ensure not only material suitability but also impeccable service. Whether grappling with the nuances of phenolic cotton sheet or the intricacies of Bakelite, expert consultation transforms decision-making from a guessing game into a strategic advantage, optimizing outcomes for manufacturers worldwide.

Conclusion

Navigating the distinctions between phenolic cotton sheet and Bakelite sheet unveils a spectrum of strengths tailored to diverse industrial needs. Phenolic cotton sheet, with its mechanical prowess, stands as a bulwark in high-wear applications, while Bakelite sheet, with its electrical finesse, anchors precision in thermal and dielectric contexts. By weighing project demands, consulting standards, and partnering with experts, manufacturers can harness these materials' unique virtues, ensuring enduring performance. The choice, though nuanced, is a gateway to innovation and efficiency in insulation solutions.

Contact Us

For more information about our range of insulating sheets, including phenolic cotton sheet and Bakelite sheet, please contact us at info@jhd-material.com. Our team of experts, with over 20 years of experience in producing and selling insulating sheets, is ready to assist you in finding the perfect solution for your industrial applications.

References

1. Baekeland, L. H. The Synthesis, Constitution, and Uses of Bakelite. Journal of Industrial and Engineering Chemistry, 1909.

2. Smith, J. R. Composite Materials in Industrial Applications: A Study of Phenolic Resins. Materials Science Review, 2015.

3. Thompson, A. K. Thermal and Electrical Properties of Thermoset Plastics. Engineering Materials Journal, 2018.

4. Patel, M. Mechanical Performance of Fabric-Reinforced Phenolic Composites. International Journal of Advanced Manufacturing, 2020.

5. Brown, E. L. Historical Perspectives on Synthetic Plastics in Electrical Insulation. Technology and Culture, 2012.

6. Nguyen, T. H. Comparative Analysis of Insulating Materials in Modern Manufacturing. Journal of Material Engineering, 2021.