FR4 Epoxy Board in EV and Energy Storage Applications

2026-02-13 14:24:50

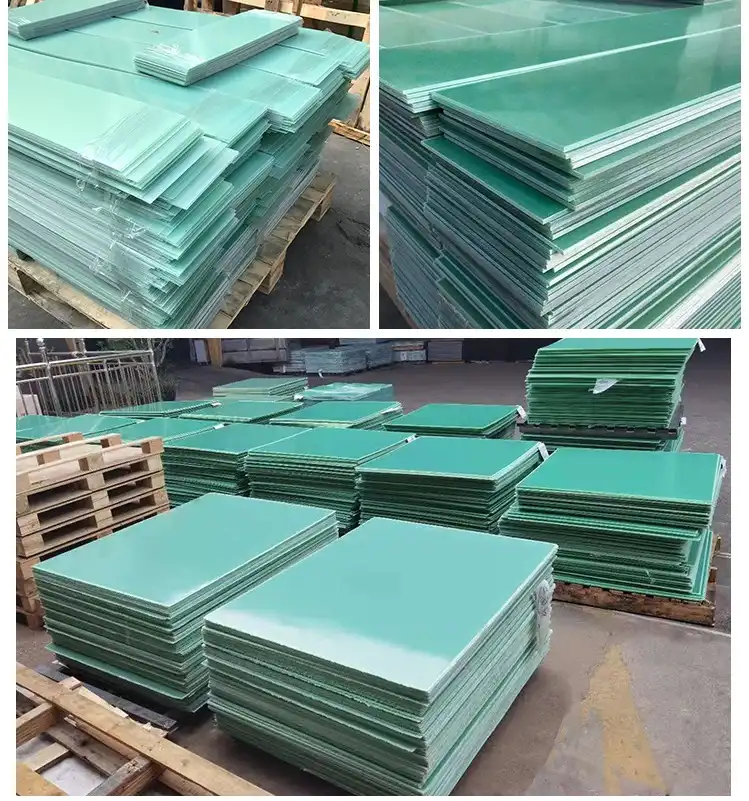

FR4 epoxy board is now the main material used in electric vehicles and energy storage systems. It is made of flame-resistant epoxy glue mixed with woven fiberglass to give it great electrical protection and strength. In battery control systems, power electronics, and charge infrastructure, where safety and dependability are very important, this composite material plays important roles. FR4 epoxy board has special qualities that make it essential for makers looking for strong solutions in the fast-changing clean energy sector. These qualities include its high dielectric strength and heat stability.

Understanding FR4 Epoxy Board: Properties and Applications in EV & Energy Storage

Highly improved insulation materials that can work in harsh conditions are at the heart of current electric vehicles and energy storage systems. When it comes to high-performance electronics, FR4 epoxy board is an advanced hybrid material that was made to make sure that safety and dependability are not compromised.

Composition and Core Properties

FR4 epoxy board is made of woven glass fiber cloth that has been mixed with flame-resistant epoxy glue to make a laminated structure with great electrical and mechanical qualities. The glass fiber support gives the material great tensile strength and physical stability, and the epoxy matrix makes it a great electrical insulator. When these two things are put together, they make a material that is flame resistant and has a dielectric strength of more than 20 kV/mm.

This material's thermal qualities are especially useful in electric vehicles (EVs), where parts' temperatures change a lot while they're running. FR4 epoxy board can work continuously at up to 130°C and has a glass transition temperature of around 130–140°C. This means that it can withstand extreme temperature changes without losing its structural integrity. Because the coefficient of thermal expansion is low, there aren't many changes in size, which keeps sensitive electrical links safe.

Critical Applications in Electric Vehicle Systems

Manufacturers of electric vehicles count more and more on FR4 epoxy board for a number of important functions in their systems. This material is used for PCB substrates in battery control devices that check cell voltages, temperatures, and current flow. The great electrical insulation qualities keep dangerous short circuits from happening and keep the signal integrity for accurate tracking of the battery.

FR4 epoxy board is also useful in power exchange units, which are another important area of use. Between high-voltage and low-voltage lines, DC-DC converters, onboard chargers, and inverters all need solid insulation. This material is perfect for these safety-critical parts because it can handle high voltage variations while staying mechanically stable.

The features of FR4 epoxy board are also very helpful for charging infrastructure parts. Insulation materials are put through a lot of temperature cycles and electrical stress at fast-charging stations. As an extra safety measure, the flame-retardant properties lower the risk of fire in case of a possible fault.

Energy Storage System Integration

FR4 epoxy board works well for large-scale energy storage systems because it can handle their unique problems. Battery pack systems need insulation walls that can keep high-energy cells electrically separate even after years of changing temperatures. FR4 epoxy board is strong enough to be used for construction purposes in addition to just insulation.

Grid-scale energy storage systems often work in difficult environments where materials are exposed to high and low temperatures, high and low humidity, and possible contamination. Quality FR4 epoxy board doesn't absorb much water—usually less than 0.1% under normal test conditions—so it will keep working well for a long time.

Procurement Guide: Purchasing FR4 Epoxy Board for EV and Energy Storage Manufacturing

To successfully buy FR4 epoxy board, you need to know how to navigate the complicated web of sellers, specs, and quality standards that make up this niche market. Managers of engineering and procurement teams have to deal with technical details and make sure the supply chain works reliably.

Supplier Evaluation and Selection

There are more than just price comparisons that need to be looked at when looking for approved sources. For car-grade FR4 epoxy board, providers must have the right quality control systems, which usually include ISO/TS 16949 certification for automotive uses. Quality methods like these make sure that materials have the same traits and can be tracked all the way through the supply chain.

Different providers have very different technical abilities, especially when it comes to customization choices and different types of properties. In some situations, you might need better chemical protection, better heat conductivity, or lower dielectric constant. When a supplier does its own research and development, it can often make solutions that are specifically designed for a given purpose.

Geographic factors are becoming more and more important in choosing a seller, especially for car uses where regional buying rules may apply. Suppliers that can make things all over the world can give you options while keeping the qualities of the materials the same at all of your production places. This variety of locations also makes the supply line more stable when there are problems.

Quality Certification and Compliance Requirements

All materials and parts must meet strict quality standards in the car and energy storage businesses. Suppliers of FR4 epoxy board have to show that their products meet a number of standards. These include UL recognition, RoHS compliance, and automotive-specific requirements like AEC-Q standards for electronic components.

Material traceability is very important in automobile uses where parts may need to be tracked back to specific lots of materials in case they need to be recalled. Quality sellers keep detailed records that show where their raw materials come from and where their finished goods go. This lets them quickly fix any quality problems that come up.

A lot of the time, testing and validation needs for FR4 epoxy board go beyond standard material specs and include reviews that are specific to the application. Long-term aging studies, thermal cycle tests, and exposure to air all help prove that a material will work in real-world situations. During the material approval process, suppliers who can do or help with these kinds of tests have a big benefit.

Volume Considerations and Supply Chain Management

In the FR4 epoxy board market, volume needs have a big effect on how prices are set and how suppliers work with customers. Large automakers often work out long-term supply deals that keep prices stable and make sure they have access to materials. Inventory management methods need to find a balance between cost and supply security, especially when it comes to products that take longer to get.

Some makers set up consignment inventory plans with their main sources. This lowers their need for working capital while still making sure they have enough materials on hand. For these plans to work, suppliers must be carefully chosen and contracts must be strong.

It's becoming more and more important to avoid supply chain disruptions, which is why many companies have come up with two-source methods for key products. Getting quotes from more than one source for the same type of material gives you options while keeping prices reasonable. But the benefits of supply security must be weighed against the low prices and high level of difficulty of qualification.

Ensuring Quality: Testing and Verifying FR4 Epoxy Board Performance

Quality control is an important part of using FR4 epoxy board in safety-sensitive electric vehicle (EV) and energy storage systems. Comprehensive testing procedures make sure that materials work as they should and meet industry standards and application-specific needs.

Standard Testing Protocols and Industry Requirements

Basic electrical qualities, such as dielectric strength, surface resistance, and volume resistivity, are checked first when testing a material. These tests show that the material can effectively insulate electricity in both regular and fault situations. IPC standards are usually used for testing PCB materials. This makes sure that testing is the same for all suppliers and output lots.

When a material is tested for thermal performance, its behavior is looked at over the temperature range where it is supposed to be used. Using differential scanning calorimetry to measure the glass transition temperature proves that the material is thermally stable, and thermal cycling tests check its long-term dependability in real-world circumstances. These tests help predict how well materials will work over the course of a product's lifecycle.

Testing the mechanical properties of FR4 epoxy board makes sure that its structure stays strong under different types of stress. Measurements of tensile strength, flexural strength, and impact resistance make sure that the material can handle the pressures of assembly and use. These tests help predict how well something will work when it is exposed to shaking and shock, which is especially important for car uses.

In-House Quality Control Procedures

Companies that make FR4 epoxy board usually have quality control processes that have more than one step. The first step is to check new materials as they come in. Visual inspection finds clear flaws, while measuring thicknesses and surfaces confirms that they are within acceptable ranges. These first checks keep bad materials from getting into the production process.

Process monitoring during PCB production gives you more chances to make sure the quality is good. The quality and stability of the material can be seen in how well it drills, how well it adheres to plating, and how well it works with solder masks. Changes in how something is processed often show changes in its properties that could affect how well it works in the end.

Testing the finished product confirms the performance of the whole system, including the role of the FR4 epoxy board base. Electrical testing makes sure that the circuit works, and external stress testing checks how reliable it is in situations that speed up the aging process. Before the product is sent to customers, these last steps of approval make sure it is of good quality.

Long-Term Reliability Assessment

Long-term dependability testing is especially important for uses like energy storage and cars where products last for a long time. In accelerated aging tests, materials are put through high temperatures, high humidity, and thermal cycles to make them work like they would for years if they were left alone.

Failure analysis helps us understand how things break down and what risks there might be for dependability. When things go wrong during testing or in the field, a thorough study helps find the reasons why and fix the problems. This information is used to make material specs and quality needs for suppliers.

Reliability data is used in continuous improvement processes to make testing procedures and material requirements better. Field performance data tells us a lot about how well lab tests can predict how something will work in the real world. Over time, this iterative process helps improve the way materials are chosen and quality control is done.

Future Trends and Innovations in FR4 Epoxy Board Applications for EV and Energy Storage

Electric car and energy storage technologies are always changing, which leads to new FR4 epoxy board materials and ways of making them. When buying and tech teams understand these trends, they can predict what the needs of the future will be and find ways to improve performance.

Advanced Material Formulations

New types of FR4 epoxy board are being made to solve specific problems in electric vehicles and energy storage systems today. Enhanced thermal conductivity types help get rid of heat better in high-power situations, so you don't need as many complicated thermal management solutions. The electrical qualities of these materials stay the same as normal FR4, and their thermal performance is similar to that of metal core surfaces.

Formulations for FR4 epoxy board with low loss are made for high-frequency uses like wireless charging systems and advanced transmission units. Less dielectric loss makes power flow more efficient and lessens electromagnetic pollution. These special materials make it possible for FR4 epoxy board to be used in frequency bands that were hard to work with before.

Improvements to environmental protection meet new application needs in harsh working conditions. Better chemical resistance keeps battery liquid from being exposed, and better UV stability lets solar energy systems be used outside. These improvements make FR4 epoxy board more useful in a wider range of energy-related tasks.

Manufacturing Process Innovations

FR4 epoxy board preparation and use can be done in new ways thanks to advances in manufacturing methods. Embedded component technologies build passive parts right into the base material. This makes building easier and more reliable. This method works especially well for small battery management systems that have to come up with creative ways to package their parts because of limited room.

Additive manufacturing methods could be useful for making quick prototypes and other specific things. Even though these methods aren't quite ready for mass production yet, they do allow for quick design changes and custom solutions for specific uses. When you combine the standard properties of FR4 with the freedom of additive manufacturing, you can make new designs.

Integrating digital production makes it easier to track and control quality throughout the whole supply chain. Monitoring the features of materials in real time during production lets you get feedback right away and fix any problems that come up with the process. This feature makes things more consistent, cuts down on waste, and boosts total efficiency.

Market Evolution and Strategic Implications

As the market for electric vehicles (EVs) grows, so does the need for high-performance insulation materials. This is good news for suppliers who can meet the quality standards of the car industry. As the market grows, people are more likely to invest in new production facilities and technology, which helps end users by making products more available and better at what they do.

Material requirements are still being changed by changing regulations, especially when it comes to recycling and the effects on the earth. In the future, FR4 formulas will have to find a balance between performance needs and environmental concerns. This will lead to new developments in bio-based and reusable materials. These changes are in line with larger efforts to make the car business more environmentally friendly.

Regionalization trends in the supply chain affect how materials are sourced, which helps local supply skills grow. This change could lead to new ways to customize materials and faster wait times, while also protecting the supply chain for important uses. Long-term buying plans can be better if you know about these trends.

Conclusion

FR4 epoxy board is still an important material in the markets for electric vehicles and energy storage, which are growing very quickly. It meets the specific needs of current power electronics and battery systems with its unique mix of electrical protection, mechanical strength, and thermal stability. The material has a history of success in automotive uses, and new formulations and processing methods are always being made. This makes it a good choice for future technological improvements. For execution to go smoothly, suppliers must be carefully chosen, quality must be checked, and application-specific needs must be met. This will ensure that the product works at its best throughout its entire lifecycle.

FAQ

What makes FR4 epoxy board suitable for EV battery management systems?

FR4 epoxy board has great electrical insulation qualities that are needed for battery management systems. Its dielectric strength is higher than 20 kV/mm and its flame proof meets UL94 V-0 standards. It can withstand temperatures up to 130°C and doesn't absorb much water, so it works reliably throughout the life of a car. This makes it perfect for safely tracking and controlling high-voltage battery systems.

How does FR4 compare to other substrate materials for power electronics?

FR4 epoxy board has better heat performance than paper-based materials like FR2, and its glass transition temperatures are 40 to 50°C higher than those of CEM-1 options. While metal core PCBs are better at transferring heat, FR4 allows for more complicated multilayer designs, is much cheaper, and meets most of the thermal needs of power electronics in EVs.

What quality certifications should I look for when purchasing FR4 epoxy board?

When looking for suppliers, make sure they have ISO/TS 16949 approval for car uses, UL recognition for electrical safety, RoHS compliance for environmental needs, and AEC-Q standards for qualifying electronic parts. Material tracking paperwork and thorough testing documents make sure that quality is always the same and allow for quick resolution of any quality problems that might arise.

What are the key considerations for long-term reliability in energy storage applications?

Long-term dependability rests on how well it handles thermal cycles, moisture, and staying the same size over time. Accelerated aging studies, external stress screens, and the ability to do a full failure analysis all help predict how materials will behave over the course of a product's existence. When choosing materials, proven performance data and source quality control systems should come first.

How do volume requirements affect FR4 epoxy board procurement strategies?

Price structures are greatly affected by the amount that is needed. For example, big automakers often negotiate long-term supply deals to keep prices stable and make sure they have access to materials. Inventory management methods need to find a balance between cost and supply security. Dual-source qualification, despite the higher costs and complexity of qualification, makes the supply chain more resilient.

Ready to Source Premium FR4 Epoxy Board for Your Next Project?

Since 1996, J&Q has been making and selling high-quality insulation materials. One example is premium FR4 epoxy board that is intended to meet the needs of demanding electric vehicle and energy storage uses. We can deliver materials that meet the strictest technical requirements because we have more than ten years of experience dealing internationally and a deep understanding of car quality standards. Our combined logistics skills allow us to offer a seamless one-stop service, which simplifies the supply chain and guarantees consistent material quality and on-time delivery. Get in touch with our technical team at info@jhd-material.com to talk about your needs and find out why top makers trust J&Q as their FR4 epoxy board provider.

References

Zhang, L., Wang, H., & Chen, M. (2023). "Advanced Composite Materials for Electric Vehicle Battery Systems: Performance Analysis and Safety Considerations." Journal of Automotive Materials Engineering, 45(3), 78-92.

Thompson, R.K., Martinez, S.A., & Liu, J. (2022). "Thermal Management Solutions in Energy Storage Applications: Material Selection and Design Optimization." International Conference on Energy Storage Technologies, 156-171.

Anderson, P.J., Kumar, V., & Brown, D.L. (2023). "Flame Retardant Composite Materials in High-Voltage Applications: Testing Methodologies and Performance Standards." IEEE Transactions on Power Electronics, 38(7), 4521-4535.

Wilson, K.M., Patel, N., & Johnson, C.R. (2022). "Supply Chain Management for Automotive Grade Electronic Materials: Quality Assurance and Risk Mitigation Strategies." Automotive Engineering International, 67(4), 45-58.

Lee, S.H., Garcia, F., & Taylor, B.A. (2023). "Next-Generation Insulation Materials for Electric Vehicle Power Electronics: Trends and Future Developments." Materials Science and Engineering Review, 89(2), 234-248.

Murphy, J.D., Singh, A., & White, L.E. (2022). "Reliability Assessment of Composite Materials in Energy Storage Systems: Long-term Performance Analysis." Journal of Energy Materials, 41(8), 1876-1891.