FR4 Sheet: Ensuring Thermal Stability in High-Frequency Applications

2025-07-29 15:17:51

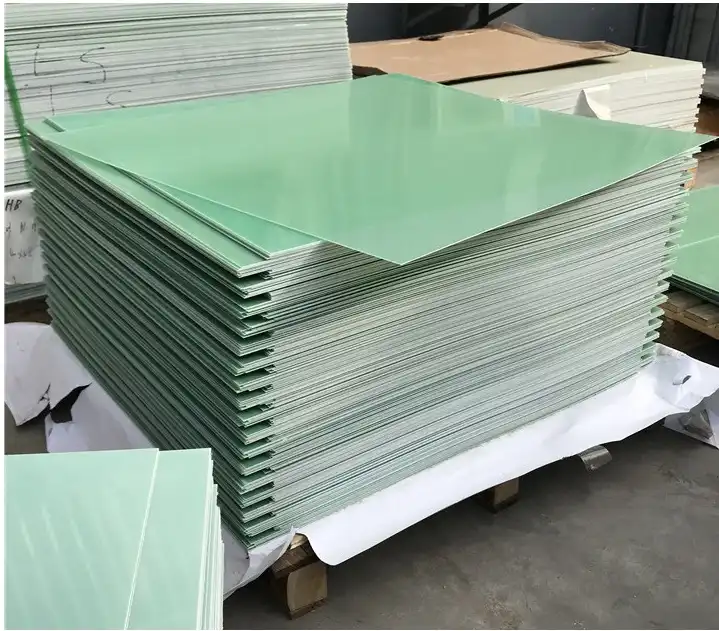

Enter the FR4 sheet, a stalwart in the realm of insulating materials that safeguards circuits from thermal havoc. This fiberglass-reinforced epoxy laminate shines in high-frequency setups, where rapid signal shifts demand unwavering stability. Its robust structure resists heat-induced deformities, preserving signal clarity even as temperatures climb. With a glass transition temperature often exceeding 130°C, FR4 endures prolonged exposure without degrading, making it ideal for telecommunications gear and aerospace components. Beyond mere endurance, it curtails thermal expansion, averting cracks in multilayer boards. Manufacturers leverage FR4 for its blend of mechanical fortitude and electrical insulation, ensuring devices operate flawlessly in demanding environments. Whether in radar systems or medical scanners, this material underpins reliability, blending flame retardancy with dielectric prowess to keep high-frequency applications humming smoothly.

Understanding FR4 Sheet Fundamentals

Diving deeper into what makes FR4 sheet a go-to choice reveals layers of ingenuity. This material, born from epoxy resin infused with fiberglass cloth, forms a composite that balances strength and insulation. Its evolution stems from needs in printed circuit boards, where precision matters most.

Composition and Material Properties

At its core, FR4 sheet comprises woven fiberglass mats saturated with brominated epoxy, granting it exceptional rigidity. This setup yields a high modulus of elasticity, resisting bends under stress. Thermal conductivity hovers around 0.3 W/mK, adequate for dissipating warmth without specialized additives. Dielectric strength surpasses 20 kV/mm, shielding against voltage spikes. Flame retardancy, compliant with stringent standards, halts fire propagation swiftly. Variants incorporate fillers like ceramic particles to tweak properties, enhancing suitability for niche demands. Such attributes position FR4 as a versatile insulator, adept at handling both mechanical and thermal loads.

Thermal Performance Metrics

Key to FR4 sheet's appeal lies in metrics like coefficient of thermal expansion, typically 14-18 ppm/°C along the plane, minimizing mismatches with copper traces. Glass transition temperature, ranging from 130°C to 180°C in high-Tg versions, marks the threshold where rigidity softens, yet integrity holds. Specific heat capacity absorbs energy efficiently, curbing rapid temperature spikes. Decomposition temperature exceeds 300°C, offering a buffer against overheating. These figures, derived from rigorous testing, ensure FR4 maintains form in cycles of heating and cooling, vital for longevity in oscillating environments.

Comparison with Alternative Materials

Stack FR4 against phenolic sheets, and its superior moisture resistance emerges, with absorption under 0.1% versus higher rates in rivals. G-10, a non-flame-retardant cousin, lacks FR4's safety edge in fire-prone settings. Polyimide options boast higher heat tolerance but at steeper costs, making FR4 economical for broad use. Ceramic substrates excel in conductivity yet falter in flexibility, where FR4 bends without fracturing. This juxtaposition underscores FR4's sweet spot: affordable reliability without sacrificing essential traits, appealing to engineers seeking balanced performance.

Applications of FR4 Sheet in High-Frequency Scenarios

FR4 sheet thrives where frequencies soar, proving its mettle in diverse fields. Its ability to uphold signal fidelity amid thermal flux makes it indispensable.

Telecommunications and Networking Equipment

In telecom hubs, FR4 forms the backbone of circuit boards handling gigabit data streams. Its low dissipation factor ensures minimal energy loss at microwave bands, preserving bandwidth. Routers and switches rely on this stability to manage heat from dense chip arrays. Base stations for 5G networks incorporate FR4 to withstand outdoor thermal variances, maintaining uptime. Signal amplifiers benefit from its impedance control, reducing crosstalk in crowded layouts. This integration keeps global connectivity seamless, even under peak loads.

Aerospace and Defense Systems

Aerospace demands push FR4 sheet to extremes, where it insulates avionics against vibrational heat. Radar arrays in aircraft use FR4 for its dimensional stability, preventing signal drift in turbulent flights. Satellite components endure space's thermal vacuums thanks to FR4's low outgassing. Missile guidance systems leverage its endurance in high-G maneuvers, where rapid heating occurs. Unmanned drones incorporate lightweight FR4 variants for efficient thermal management in compact frames. Such roles highlight FR4's resilience in mission-critical ops.

Consumer Electronics and Automotive Integration

Smartphones pack FR4 into slim profiles, managing heat from processors running at high clocks. Automotive infotainment systems use it to insulate against engine bay warmth, ensuring glitch-free operation. Electric vehicle battery controls depend on FR4 for safe power routing amid thermal cycles. Wearables like smartwatches benefit from its conformability, fitting curved designs without thermal weak points. Home appliances, from smart refrigerators to IoT hubs, embed FR4 for reliable high-speed connectivity. This widespread adoption showcases FR4's adaptability in everyday tech.

Enhancing Thermal Stability with FR4 Sheet

To maximize FR4's potential, savvy approaches amplify its thermal prowess. Tailored designs and selections elevate performance.

Design Strategies for Optimal Heat Management

Layering FR4 with copper planes creates natural heat sinks, spreading warmth evenly across boards. Via arrays facilitate vertical dissipation, channeling heat away from hotspots. Incorporating thermal relief patterns prevents solder joint stress during expansions. Multilayer configurations intersperse insulating FR4 with conductive paths, balancing impedance and cooling. Edge plating adds peripheral heat escape routes, ideal for dense assemblies. These tactics transform standard FR4 into a thermal guardian, extending device lifespans.

Testing and Quality Assurance Protocols

Rigorous evaluations like thermal shock tests cycle FR4 through temperature extremes, verifying crack resistance. Differential scanning calorimetry measures transition points accurately, guiding material tweaks. Infrared thermography maps heat distributions in real-time, spotting anomalies early. Peel strength assessments ensure laminate bonds hold under thermal duress. Accelerated life testing simulates years of use, predicting failures. Adhering to these protocols guarantees FR4 sheets meet exacting standards, fostering trust in their stability.

Selecting Suppliers for Reliable FR4 Materials

Partnering with seasoned producers, like those with decades in insulating sheets, ensures consistent quality. Look for certifications in material purity, avoiding contaminants that impair thermal traits. Traceability from raw inputs to finished sheets builds confidence. Customization options, such as thickness variations, cater to specific thermal needs. Long-term collaborations yield insights into evolving FR4 tech, like lead-free formulations. Opting for global suppliers with export expertise streamlines procurement, delivering FR4 that upholds thermal vows reliably.

Conclusion

In wrapping up, FR4 sheet stands as a cornerstone for thermal stability in high-frequency realms, blending durability with efficiency. Its properties mitigate heat-related pitfalls, supporting innovations across industries. From telecom to aerospace, this material enables devices to perform under pressure, reducing downtime and enhancing safety. As technology advances, FR4 evolves, incorporating greener compositions without losing its edge. Embracing it means investing in reliability that pays dividends in performance and longevity. For manufacturers navigating global demands, FR4 offers a proven path to excellence.

Contact Us

Ready to explore how FR4 sheet can elevate your projects? Reach out to our team with over 20 years in insulating sheet production and a decade in foreign trade. We partner with top domestic and international firms to deliver top-tier service. Contact us at info@jhd-material.com for tailored insights and quotes.

References

1. IPC-4101E: Specification for Base Materials for Rigid and Multilayer Printed Boards, published by IPC International, 2017.

2. "Printed Circuit Board Materials Handbook" by Martin W. Jawitz, McGraw-Hill, 1997.

3. "High-Frequency Characterization of FR-4 Substrates for Multilayer PCBs" in IEEE Transactions on Components, Packaging and Manufacturing Technology, Volume 1, Issue 7, 2011.

4. UL 94: Standard for Safety of Flammability of Plastic Materials for Parts in Devices and Appliances, Underwriters Laboratories, 2020 edition.

5. "Thermal Management of Electronic Systems" by Kaveh Azar, CRC Press, 2000.

6. ASTM D709: Standard Specification for Laminated Thermosetting Materials, ASTM International, 2017.