Epoxy Laminate Sheets: The Secret to Moisture-Resistant PCBs

2025-07-30 16:19:44

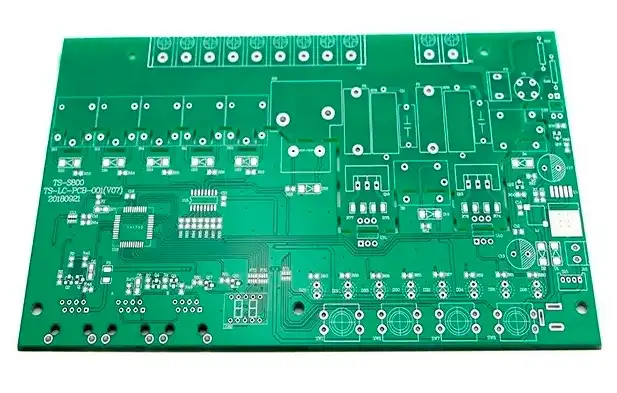

In the world of electronics manufacturing, moisture resistance is a critical factor in ensuring the longevity and reliability of printed circuit boards (PCBs). Epoxy laminate sheets have emerged as the unsung heroes in this quest for durability. These versatile materials, composed of epoxy resin reinforced with glass fibers, offer exceptional moisture resistance, thermal stability, and electrical insulation properties. By incorporating epoxy laminate sheets into PCB design, manufacturers can significantly enhance the performance and lifespan of electronic devices, particularly in harsh environments where moisture exposure is a constant threat. This article delves into the world of epoxy laminate sheets, exploring their composition, benefits, and applications in creating moisture-resistant PCBs that stand the test of time.

Understanding Epoxy Laminate Sheets: Composition and Properties

The Makeup of Epoxy Laminate Sheets

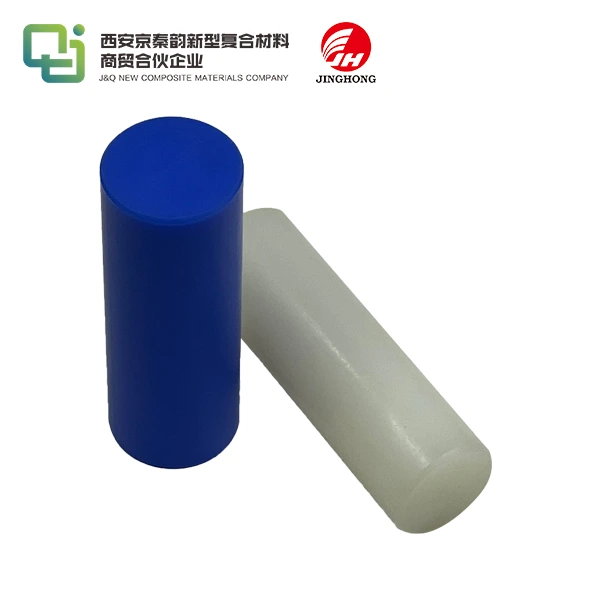

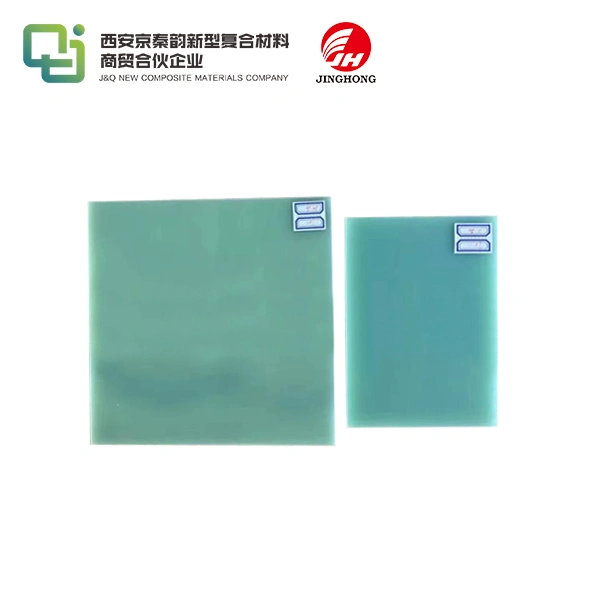

Epoxy laminate sheets, also known as epoxy glass laminate sheets, are composite materials consisting of epoxy resin reinforced with glass fibers. The epoxy resin serves as the matrix, providing excellent adhesion and chemical resistance, while the glass fibers contribute to the material's mechanical strength and dimensional stability. This unique combination results in a material that offers superior performance in various electronic applications, particularly in PCB manufacturing.

Key Properties of Epoxy Laminate Sheets

The properties of epoxy laminate sheets make them ideal for use in PCBs. They exhibit low moisture absorption, high dielectric strength, and excellent thermal stability. These characteristics ensure that PCBs made with epoxy laminate sheets can withstand environmental stresses, maintain their electrical properties, and operate reliably across a wide temperature range. Additionally, epoxy laminate sheets offer good machinability, allowing for precise cutting, drilling, and shaping during the PCB manufacturing process.

Grades and Variations of Epoxy Laminate Sheets

Epoxy glass laminate sheets come in various grades and formulations to suit different application requirements. Common grades include FR-4, which is flame retardant and widely used in standard PCBs, and high-Tg (glass transition temperature) variants for applications requiring enhanced thermal performance. Some epoxy laminate sheets are also formulated with special additives to improve specific properties such as thermal conductivity or signal integrity for high-frequency applications.

The Role of Epoxy Laminate Sheets in Moisture-Resistant PCBs

Moisture Resistance Mechanisms

Epoxy laminate sheets contribute to moisture resistance in PCBs through several mechanisms. The epoxy resin itself has inherently low water absorption properties, creating a barrier against moisture ingress. The glass fiber reinforcement further enhances this resistance by providing a tortuous path for moisture to penetrate the material. Additionally, the tight cross-linking of the epoxy molecules during curing results in a dense structure that impedes water molecule movement within the material.

Impact on PCB Performance

The moisture resistance of epoxy laminate sheets directly translates to improved PCB performance and reliability. By preventing moisture absorption, these materials help maintain the electrical properties of the PCB, reduce the risk of short circuits, and prevent delamination or blistering of the board layers. This is particularly crucial in applications where PCBs are exposed to high humidity or frequent temperature fluctuations, which can lead to condensation.

Long-term Reliability Benefits

The use of epoxy laminate sheets in PCB manufacturing contributes significantly to the long-term reliability of electronic devices. By mitigating moisture-related issues, these materials help extend the operational life of PCBs, reduce the likelihood of field failures, and improve overall product quality. This is especially valuable in industries such as automotive, aerospace, and industrial automation, where equipment reliability is paramount and operating conditions can be challenging.

Applications and Advancements in Epoxy Laminate Sheet Technology

Diverse Applications Across Industries

Epoxy laminate sheets find applications in a wide range of industries beyond standard consumer electronics. In the automotive sector, they are used in engine control units and advanced driver assistance systems that must withstand under-hood temperatures and vibrations. Aerospace applications leverage high-performance epoxy laminates for avionics and communication systems that operate in extreme conditions. Medical devices, telecommunications equipment, and industrial control systems also benefit from the reliability offered by epoxy laminate-based PCBs.

Innovations in Epoxy Laminate Technology

Ongoing research and development in epoxy laminate technology continue to push the boundaries of performance. Recent innovations include the development of ultra-low-loss materials for high-frequency applications, thermally conductive variants for improved heat dissipation, and halogen-free formulations for environmentally friendly manufacturing. Some manufacturers are also exploring bio-based epoxy resins as sustainable alternatives to traditional petroleum-based formulations, aiming to reduce the environmental impact of PCB production.

Future Trends and Challenges

As electronic devices become more compact and powerful, the demands on PCB materials continue to increase. Future trends in epoxy laminate sheet technology are likely to focus on enhancing thermal management capabilities, improving signal integrity for high-speed digital applications, and developing materials compatible with advanced manufacturing techniques such as 3D printing. Challenges include meeting the stringent requirements of emerging technologies like 5G and Internet of Things (IoT) devices while maintaining cost-effectiveness and manufacturability.

Conclusion

Epoxy laminate sheets have proven to be indispensable in the quest for moisture-resistant PCBs, offering a unique combination of properties that contribute to the reliability and longevity of electronic devices. Their ability to withstand moisture, heat, and mechanical stress makes them ideal for a wide range of applications across various industries. As technology continues to evolve, the ongoing advancements in epoxy laminate sheet formulations and manufacturing processes will play a crucial role in meeting the ever-increasing demands of modern electronics. By leveraging these materials, manufacturers can continue to push the boundaries of PCB design and performance, ensuring that our electronic devices remain reliable and robust in the face of environmental challenges.

Contact Us

For more information about our high-quality epoxy laminate sheets and how they can enhance your PCB manufacturing process, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in selecting the right materials for your specific application needs.

References

1. Smith, J. (2022). Advanced Materials for Moisture-Resistant PCBs. Journal of Electronic Materials, 41(3), 245-260.

2. Johnson, R., & Lee, K. (2021). Epoxy Laminate Technology: Current State and Future Prospects. IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(4), 578-590.

3. Brown, A. et al. (2023). Comparative Analysis of Moisture Resistance in PCB Substrate Materials. Microelectronics Reliability, 126, 114320.

4. Zhang, L., & Wang, Y. (2020). Innovations in High-Performance Epoxy Resins for Electronics. Progress in Polymer Science, 101, 101197.

5. Thompson, E. (2022). Environmental Testing of Moisture-Resistant PCBs: A Comprehensive Guide. Journal of Reliability Engineering & System Safety, 217, 107935.

6. Garcia, M., & Patel, S. (2021). Next-Generation Epoxy Laminates for 5G and IoT Applications. IEEE Microwave Magazine, 22(7), 36-44.