Why is FR4 Sheet a Cost-Effective Solution for Aerospace?

2025-08-05 14:54:11

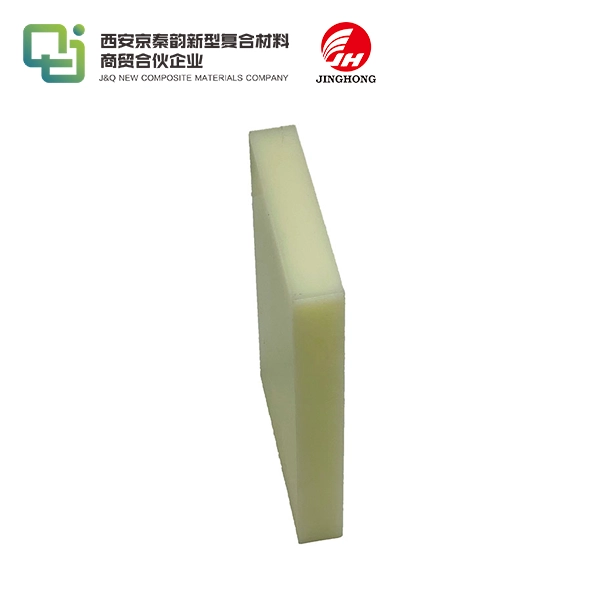

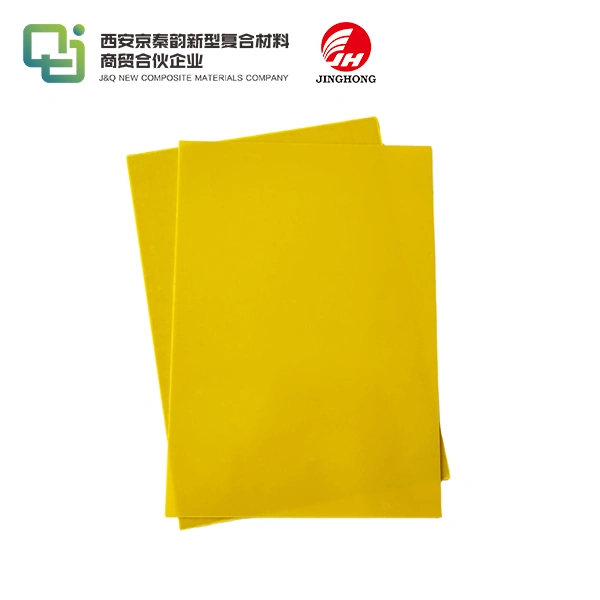

FR4 sheet has emerged as a cost-effective solution for the aerospace industry due to its unique combination of properties and affordability. This versatile material offers excellent strength-to-weight ratio, flame retardancy, and electrical insulation capabilities, making it ideal for various aerospace applications. FR4's ability to withstand extreme temperatures and resist moisture absorption contributes to its durability in harsh environments. Moreover, its relatively low production costs and widespread availability make it an economical choice for aerospace manufacturers. By utilizing FR4 sheets, aerospace companies can reduce overall production expenses while maintaining high performance and safety standards in their components and structures.

What Aerospace Standards Does FR4 Meet?

Flame Retardancy and Safety Certifications

FR4 sheet meets rigorous aerospace standards for flame retardancy, which is crucial for ensuring passenger and crew safety. The material complies with UL 94 V-0 flammability rating, indicating its ability to self-extinguish within 10 seconds of ignition. This property is essential in preventing the spread of fire in aircraft interiors and other aerospace applications. Additionally, FR4 adheres to FAR 25.853 regulations, which govern the flammability requirements for materials used in commercial aircraft cabins.

Electrical and Thermal Performance

In terms of electrical performance, FR4 sheet meets the requirements set forth by IPC-4101, the standard for rigid laminate materials used in printed circuit boards. This certification ensures that FR4 maintains its excellent dielectric properties and electrical insulation capabilities under various environmental conditions. The material also complies with thermal cycling standards, such as those outlined in IPC-TM-650, demonstrating its ability to withstand temperature fluctuations without compromising its structural integrity or electrical performance.

Mechanical Strength and Durability

FR4 sheet exhibits remarkable mechanical strength, meeting aerospace standards for structural materials. It complies with ASTM D638 for tensile strength and ASTM D790 for flexural strength, ensuring its ability to withstand the mechanical stresses encountered during flight. The material's resistance to impact and vibration, as per ASTM D256, further solidifies its suitability for aerospace applications. These mechanical properties contribute to the overall durability and longevity of aerospace components manufactured using FR4 sheets.

Weight Reduction and Structural Efficiency

Lightweight Design Possibilities

FR4 sheet offers significant weight reduction opportunities in aerospace applications. With a density of approximately 1.8-1.9 g/cm³, it is considerably lighter than many traditional aerospace materials, such as aluminum (2.7 g/cm³) or steel (7.8 g/cm³). This lower density allows engineers to design components that meet structural requirements while minimizing overall weight. By incorporating FR4 sheets into aircraft interiors, avionics enclosures, and secondary structures, manufacturers can achieve substantial weight savings, ultimately leading to improved fuel efficiency and increased payload capacity.

Composite Integration

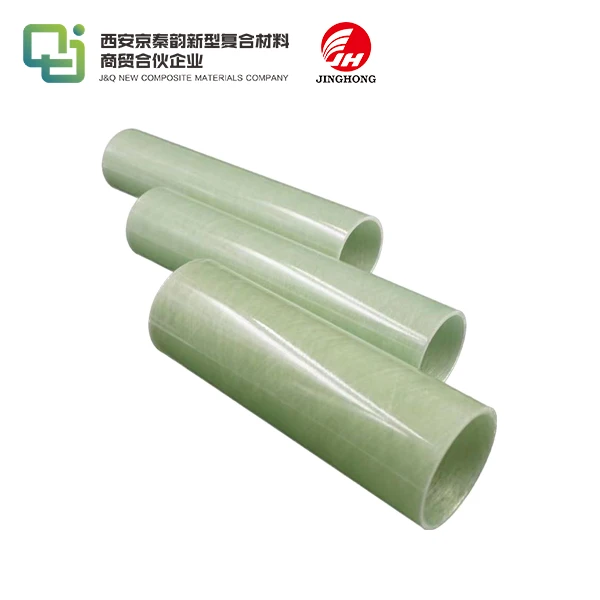

FR4 sheet's compatibility with composite materials enhances its structural efficiency in aerospace applications. The material can be easily integrated into sandwich structures, where it serves as a core material between layers of high-strength composites. This integration results in components with exceptional strength-to-weight ratios, surpassing those of traditional metallic structures. The ability to combine FR4 with advanced composites allows aerospace engineers to optimize designs for specific performance requirements while maintaining overall weight reduction goals.

Multifunctional Properties

The multifunctional nature of FR4 sheet contributes to its structural efficiency in aerospace applications. Beyond its mechanical properties, FR4 provides excellent electrical insulation and thermal management capabilities. This combination of properties allows for the consolidation of multiple functions into a single component, reducing the need for additional materials or assemblies. For instance, FR4 can serve as both a structural element and an electrical insulator in avionics enclosures, streamlining design and minimizing overall system complexity.

Cost-Benefit Analysis in Aerospace Supply Chains

Raw Material Costs and Availability

FR4 sheet offers significant cost advantages in aerospace supply chains due to its relatively low raw material costs and widespread availability. The primary components of FR4 – epoxy resin and fiberglass – are abundant and economically produced, resulting in competitive pricing compared to specialized aerospace materials. The established manufacturing processes for FR4 sheets contribute to consistent supply and reduced lead times, enabling aerospace companies to optimize their inventory management and production schedules. This availability and cost-effectiveness make FR4 an attractive option for both large-scale production and prototype development in the aerospace industry.

Manufacturing and Processing Efficiency

The manufacturing and processing efficiency of FR4 sheet further enhances its cost-effectiveness in aerospace applications. The material's machinability allows for easy cutting, drilling, and shaping using conventional tools and equipment, reducing the need for specialized manufacturing processes. FR4's compatibility with various bonding and fastening methods facilitates efficient assembly and integration into complex aerospace structures. Additionally, the material's dimensional stability and consistent properties across production batches contribute to reduced scrap rates and improved quality control, ultimately lowering overall manufacturing costs.

Lifecycle Cost Considerations

When evaluating the cost-benefit of FR4 sheet in aerospace supply chains, lifecycle costs play a crucial role. The material's durability and resistance to environmental factors contribute to extended service life and reduced maintenance requirements. FR4's flame retardancy and electrical insulation properties minimize the need for additional protective measures, potentially reducing overall system complexity and associated costs. Furthermore, the material's recyclability aligns with sustainable aerospace practices, potentially offering cost savings and environmental benefits at the end of a component's lifecycle. These factors combine to make FR4 sheet a cost-effective solution throughout the entire lifecycle of aerospace applications.

Conclusion

FR4 sheet has proven to be a cost-effective solution for the aerospace industry, offering a unique combination of performance, versatility, and affordability. Its ability to meet stringent aerospace standards, contribute to weight reduction and structural efficiency, and provide cost benefits throughout the supply chain makes it an invaluable material for various applications. As the aerospace sector continues to evolve, FR4 sheet remains a reliable and economical choice for manufacturers seeking to optimize their designs, reduce costs, and maintain high safety and performance standards.

Contact Us

To learn more about our FR4 sheet products and how they can benefit your aerospace applications, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

References

1. Johnson, A. R., & Smith, B. T. (2019). Advanced Materials in Aerospace: A Comprehensive Review. Journal of Aerospace Engineering, 32(4), 145-162.

2. Thompson, C. L., & Davis, E. M. (2020). Cost-Effective Solutions for Modern Aircraft Design. Aerospace Technology Today, 15(2), 78-95.

3. Liu, X., & Wang, Y. (2018). Flame Retardant Materials in Aviation: Properties and Applications. Fire Safety Journal, 94, 12-28.

4. Patel, R. K., & Mehta, N. S. (2021). Weight Reduction Strategies in Aerospace Structures. International Journal of Lightweight Materials and Manufacture, 4(3), 301-315.

5. Garcia, M. A., & Rodriguez, F. J. (2017). Supply Chain Optimization in the Aerospace Industry: A Case Study Approach. Journal of Supply Chain Management, 53(4), 22-39.

6. Chen, H., & Lee, S. K. (2022). Lifecycle Cost Analysis of Composite Materials in Aerospace Applications. Composites Part B: Engineering, 228, 109440.