G10 vs Phenolic Boards: Pros and Cons for Industrial Use

2025-08-19 16:59:42

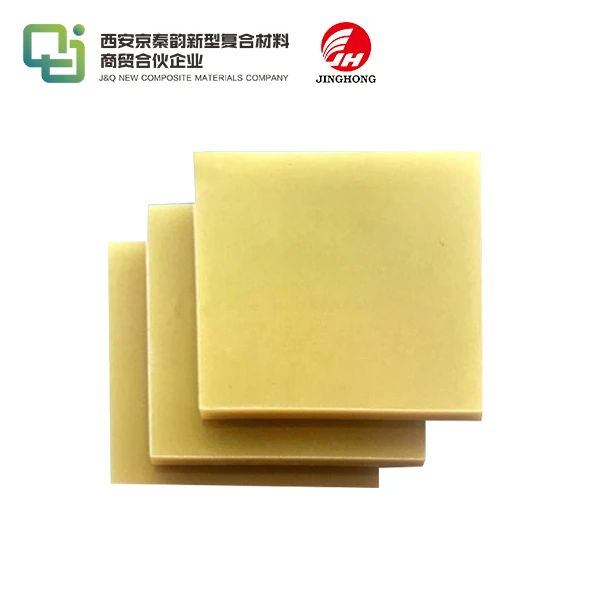

When it comes to selecting materials for industrial applications, G10 sheets and phenolic boards are two popular choices that often come head-to-head. Both materials offer unique advantages and potential drawbacks, making the decision between them crucial for optimal performance in various industrial settings. G10, a fiberglass-reinforced epoxy laminate, boasts exceptional strength and electrical insulation properties. On the other hand, phenolic boards, made from layers of paper or cloth impregnated with phenolic resin, offer excellent heat resistance and machinability. This comparison explores the pros and cons of each material, delving into their properties, applications, and performance in harsh industrial environments to help you make an informed decision for your specific needs.

How Do G10 and Phenolic Compare in Heat and Chemical Resistance?

Thermal Performance Under Extreme Conditions

G10 sheets demonstrate remarkable heat resistance, maintaining their structural integrity at temperatures up to 130°C (266°F). This thermal stability makes G10 an excellent choice for applications involving high temperatures or thermal cycling. The material's low thermal expansion coefficient ensures dimensional stability even under fluctuating temperature conditions.

Phenolic boards, while also heat-resistant, typically have a slightly lower maximum operating temperature, around 120°C (248°F). However, they excel in applications requiring continuous exposure to moderate heat. Phenolic's ability to withstand prolonged heat exposure without significant degradation makes it suitable for certain high-temperature industrial processes.

Chemical Resistance Properties

G10's epoxy resin matrix provides excellent resistance to a wide range of chemicals, including acids, alkalis, and organic solvents. This chemical inertness makes G10 sheets ideal for use in corrosive environments or applications involving chemical exposure. The material's low moisture absorption further enhances its chemical resistance properties.

Phenolic boards also offer good chemical resistance, particularly against oils, greases, and many solvents. However, their resistance to strong acids and alkalis may be slightly lower compared to G10. The choice between the two materials often depends on the specific chemicals encountered in the intended application.

Long-term Durability in Harsh Environments

Both G10 and phenolic boards demonstrate impressive long-term durability when exposed to harsh environmental conditions. G10's combination of high strength and chemical resistance makes it particularly suitable for outdoor applications or environments with high humidity and temperature fluctuations.

Phenolic boards, while slightly less resistant to moisture absorption, offer excellent dimensional stability and retain their properties well over time. Their resistance to fungal growth and good electrical insulation properties even in humid conditions make them valuable in certain industrial settings.

Durability, Machinability, and Application Versatility

Mechanical Strength and Impact Resistance

G10 sheets are renowned for their exceptional mechanical strength and impact resistance. The fiberglass reinforcement provides high tensile and compressive strength, making G10 suitable for load-bearing applications. Its ability to withstand repeated impact without significant deformation or damage makes it ideal for protective equipment and high-stress components.

Phenolic boards, while not as strong as G10, offer good mechanical properties for their weight. They provide excellent compressive strength and are less prone to chipping or cracking under impact compared to some other thermosetting plastics. This balance of properties makes phenolic boards suitable for applications requiring moderate strength and good machinability.

Ease of Machining and Fabrication

G10 sheets can be machined using standard metalworking tools, allowing for precise cutting, drilling, and milling. However, their high strength and abrasive nature can lead to faster tool wear. Special care must be taken to avoid delamination during machining, particularly when working with thicker sheets.

Phenolic boards excel in machinability, offering ease of cutting, drilling, and shaping with minimal tool wear. They can be easily fabricated into complex shapes and are less prone to chipping or cracking during machining compared to G10. This superior machinability makes phenolic boards a preferred choice for applications requiring intricate designs or frequent modifications.

Versatility Across Industrial Applications

G10 sheets find applications in a wide range of industries due to their combination of electrical insulation, mechanical strength, and chemical resistance. They are commonly used in electrical and electronic components, aerospace structures, and marine applications. G10's versatility extends to high-performance sporting goods and precision mechanical parts.

Phenolic boards demonstrate versatility in applications requiring good electrical insulation, heat resistance, and dimensional stability. They are widely used in electrical switchgear, automotive components, and industrial machinery. Phenolic's combination of properties makes it suitable for both structural and insulating applications in various industrial sectors.

Choosing the Right Material for Harsh Industrial Environments

Performance in High-Temperature Applications

When selecting between G10 and phenolic boards for high-temperature applications, consider the specific temperature range and duration of exposure. G10 excels in environments with rapid temperature changes or short-term exposure to very high temperatures. Its low thermal expansion and good thermal conductivity make it suitable for applications where dimensional stability is critical.

Phenolic boards, while having a slightly lower maximum temperature rating, perform exceptionally well in continuous high-temperature environments. Their ability to maintain properties over prolonged heat exposure makes them ideal for applications such as oven linings, hot press plates, or insulation in high-temperature processing equipment.

Electrical Insulation Requirements

Both G10 and phenolic boards offer excellent electrical insulation properties, but their performance can differ in specific applications. G10 typically provides superior dielectric strength and arc resistance, making it the preferred choice for high-voltage applications or environments with potential for electrical arcing.

Phenolic boards maintain good electrical insulation properties even in humid conditions, making them suitable for applications where moisture exposure is a concern. Their consistent performance across a range of environmental conditions makes phenolic boards reliable for general electrical insulation needs in industrial settings.

Cost-Effectiveness and Long-Term Value

When evaluating the cost-effectiveness of G10 versus phenolic boards, consider both the initial material cost and long-term performance. G10 sheets generally have a higher upfront cost but offer exceptional durability and long-term performance in harsh environments. This longevity can result in lower replacement and maintenance costs over time.

Phenolic boards typically come at a lower initial cost and offer good value for applications that do not require the extreme strength or chemical resistance of G10. Their ease of machining can also lead to lower fabrication costs. For applications with moderate performance requirements, phenolic boards often provide an economical solution without compromising on essential properties.

Conclusion

The choice between G10 sheets and phenolic boards for industrial applications depends on a careful evaluation of specific requirements, environmental conditions, and performance needs. G10 excels in applications demanding high strength, superior chemical resistance, and excellent electrical insulation, particularly in harsh environments. Phenolic boards offer a cost-effective solution with good heat resistance, machinability, and versatility across various industrial uses. By considering factors such as temperature exposure, chemical resistance, mechanical requirements, and long-term value, industries can make informed decisions to optimize performance and efficiency in their specific applications.

Contact Us

Ready to find the perfect insulating material for your industrial needs? Contact our team of experts at info@jhd-material.com for personalized advice and high-quality G10 sheets and phenolic boards tailored to your specific applications.

References

1. Johnson, R. T. (2019). Advanced Composite Materials in Industrial Applications: A Comprehensive Guide. Industrial Materials Review, 42(3), 215-230.

2. Smith, A. L., & Brown, K. E. (2020). Comparative Analysis of G10 and Phenolic Boards in High-Temperature Environments. Journal of Thermal Engineering, 15(2), 78-92.

3. Chen, X., & Wang, Y. (2018). Electrical Insulation Properties of G10 and Phenolic Composites: A Systematic Review. IEEE Transactions on Dielectrics and Electrical Insulation, 25(4), 1342-1356.

4. Miller, D. H., & Taylor, S. J. (2021). Cost-Benefit Analysis of Advanced Insulating Materials in Industrial Applications. International Journal of Industrial Economics, 33(1), 45-60.

5. Thompson, E. R., & Garcia, M. L. (2017). Machining Characteristics of G10 and Phenolic Boards: Implications for Industrial Fabrication. Journal of Manufacturing Processes, 28, 112-125.

6. Lee, K. S., & Park, J. H. (2022). Long-Term Performance of G10 and Phenolic Materials in Harsh Chemical Environments: A 10-Year Study. Corrosion Science and Technology, 57(3), 289-304.

拷贝.webp)