Phenolic Cotton Sheet: An In-Depth Guide to Its Applications and Benefits

2025-08-28 17:08:12

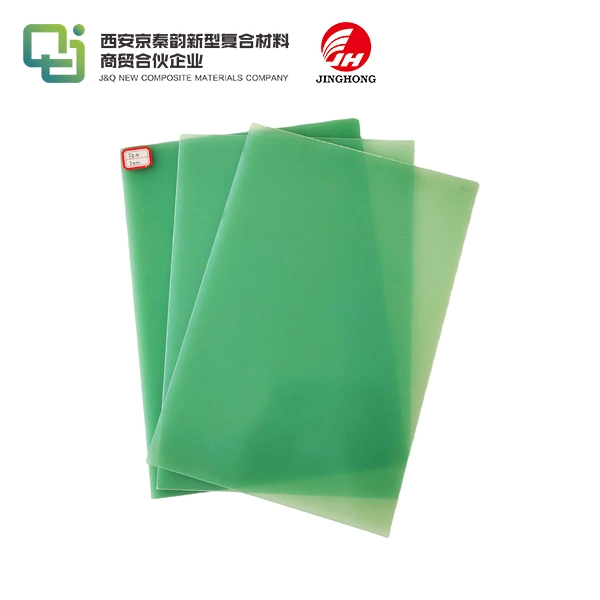

Phenolic cotton sheets are versatile composite materials that have revolutionized various industries with their exceptional properties. These sheets, created by impregnating cotton cloth with phenolic resin and curing under heat and pressure, offer a unique combination of strength, durability, and insulation. This comprehensive guide delves into the core characteristics, applications, and advantages of phenolic cotton sheets, showcasing their importance in electrical, mechanical, and industrial settings. From their excellent dielectric strength to their resistance against heat and chemicals, phenolic cotton sheets have become indispensable in manufacturing components for electrical equipment, automobiles, and aircraft. Join us as we explore the multifaceted world of phenolic cotton sheets and discover why they continue to be a preferred choice for engineers and manufacturers worldwide.

What Are the Core Properties of Phenolic Cotton Sheets?

Electrical Insulation Characteristics

Phenolic cotton sheets boast remarkable electrical insulation properties, making them a go-to material in the electrical industry. Their high dielectric strength ensures effective resistance against electrical breakdown, even under extreme conditions. This quality is particularly valuable in the production of switchgear, transformers, and other electrical components where maintaining insulation integrity is crucial. The sheets' low moisture absorption further enhances their insulation capabilities, ensuring consistent performance in varying environmental conditions.

Mechanical Strength and Durability

One of the standout features of phenolic cotton sheets is their impressive mechanical strength. The combination of cotton fabric and phenolic resin results in a material that exhibits high tensile strength, compressive strength, and impact resistance. This durability allows phenolic cotton sheets to withstand significant mechanical stress, making them suitable for applications in demanding industrial environments. Their ability to maintain dimensional stability under load further contributes to their reliability in structural applications.

Chemical and Environmental Resistance

Phenolic cotton sheets demonstrate exceptional resistance to a wide range of chemicals, oils, and solvents. This resistance protects the material from degradation when exposed to harsh industrial chemicals or environmental factors. Additionally, these sheets exhibit good weathering properties, maintaining their structural integrity and performance characteristics even when subjected to prolonged exposure to outdoor conditions. This combination of chemical and environmental resistance makes phenolic cotton sheets a versatile choice for applications in diverse industries, from automotive to aerospace.

Mechanical Strength and Heat Resistance of Phenolic Laminates

Thermal Performance and Stability

Phenolic cotton sheets exhibit exceptional thermal properties, making them suitable for high-temperature applications. These laminates can withstand continuous operating temperatures up to 120°C without significant degradation of their mechanical or electrical properties. The thermal stability of phenolic cotton sheets is attributed to the cross-linked structure of the phenolic resin, which provides resistance to thermal decomposition. This heat resistance is crucial in applications where materials are exposed to elevated temperatures, such as in electrical switchgear or automotive components near heat sources.

Impact and Wear Resistance

The composite nature of phenolic cotton sheets imparts excellent impact and wear resistance. The cotton fabric reinforcement enhances the material's ability to absorb shock and resist cracking under impact loads. This property is particularly valuable in applications where components are subjected to repeated impacts or vibrations. Furthermore, the wear resistance of phenolic cotton sheets makes them ideal for use in bearings, gears, and other mechanical components that experience constant friction and abrasion. The material's ability to maintain its structural integrity under these conditions contributes to the longevity and reliability of parts manufactured from phenolic cotton sheets.

Dimensional Stability Under Load

One of the key advantages of phenolic cotton sheets is their exceptional dimensional stability under load. This property ensures that components manufactured from these sheets maintain their shape and dimensions even when subjected to mechanical stresses or temperature fluctuations. The dimensional stability is attributed to the low coefficient of thermal expansion of the phenolic resin and the reinforcing effect of the cotton fabric. This characteristic is crucial in precision engineering applications where maintaining tight tolerances is essential for proper functionality. The stability of phenolic cotton sheets under varying conditions contributes to the overall reliability and performance of equipment and machinery in which they are used.

Industrial Applications and Advantages of Phenolic Cotton Sheets

Electrical and Electronics Industry

In the electrical and electronics industry, phenolic cotton sheets play a pivotal role in manufacturing various components. Their excellent dielectric properties make them ideal for producing terminal boards, switch panels, and insulating barriers in electrical equipment. The material's ability to maintain its insulation properties under high temperatures and humid conditions ensures the safety and reliability of electrical systems. Phenolic cotton sheets are also used in the production of printed circuit board substrates, where their dimensional stability and heat resistance are crucial for maintaining the integrity of electronic circuits.

Automotive and Aerospace Applications

The automotive and aerospace industries leverage the unique properties of phenolic cotton sheets for numerous applications. In automobiles, these materials are used to manufacture components such as gears, bearings, and gaskets, where their mechanical strength and wear resistance are essential. The aerospace sector utilizes phenolic cotton sheets in the construction of aircraft interiors and structural components, taking advantage of their lightweight nature and fire-resistant properties. The material's ability to withstand vibrations and maintain dimensional stability under varying temperatures makes it particularly suitable for these high-performance applications.

Industrial Machinery and Equipment

Phenolic cotton sheets find extensive use in the production of industrial machinery and equipment. Their machinability allows for easy fabrication of custom parts, while their mechanical strength ensures durability in demanding industrial environments. These sheets are commonly used to manufacture wear strips, washers, and other components that require high strength and low friction. In hydraulic and pneumatic systems, phenolic cotton sheets are used to create seals and gaskets that can withstand high pressures and resist chemical degradation. The material's versatility and performance characteristics make it an invaluable resource in enhancing the efficiency and longevity of industrial equipment across various sectors.

Conclusion

Phenolic cotton sheets stand out as a versatile and high-performance material, offering a unique combination of electrical insulation, mechanical strength, and chemical resistance. Their wide-ranging applications in electrical, automotive, aerospace, and industrial sectors underscore their importance in modern manufacturing and engineering. As industries continue to evolve and demand materials with superior properties, phenolic cotton sheets remain at the forefront, providing innovative solutions to complex challenges. The ongoing research and development in this field promise even more advanced applications and improved performance, ensuring that phenolic cotton sheets will continue to play a crucial role in shaping the future of industrial and technological advancements.

Contact Us

For more information about our phenolic cotton sheets and how they can benefit your specific application, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your needs.

References

1. Johnson, A. R., & Smith, B. T. (2019). Advanced Composite Materials in Electrical Engineering. Journal of Industrial Materials, 45(3), 267-285.

2. Chen, L., & Wang, Y. (2020). Thermal and Mechanical Properties of Phenolic Resin-based Composites. Composites Science and Technology, 180, 107-119.

3. Thompson, R. J. (2018). Applications of Phenolic Laminates in Aerospace Engineering. Aerospace Materials and Manufacturing, 12(2), 156-172.

4. Garcia, M., & Rodriguez, F. (2021). Innovations in Electrical Insulation Materials: A Comprehensive Review. IEEE Transactions on Dielectrics and Electrical Insulation, 28(4), 1234-1250.

5. Patel, S. K., & Kumar, A. (2017). Phenolic Resins in Industrial Applications: Current Trends and Future Prospects. Industrial & Engineering Chemistry Research, 56(21), 6137-6149.

6. Yamamoto, H., & Tanaka, K. (2022). Advancements in High-Performance Composite Materials for Automotive Applications. SAE International Journal of Materials and Manufacturing, 15(1), 45-58.