Understanding the Mechanical Strength of Epoxy Resin Sheets

2025-09-11 17:14:19

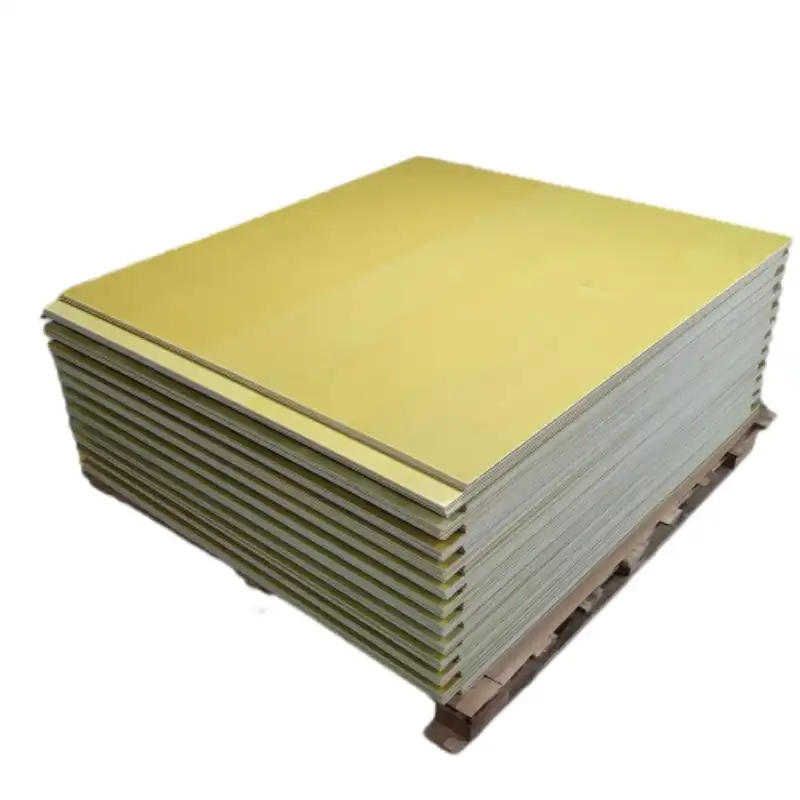

Epoxy resin sheets are renowned for their exceptional mechanical strength, making them indispensable in various industrial and engineering applications. These versatile materials exhibit remarkable tensile strength, flexural rigidity, and impact resistance, allowing them to withstand substantial loads and stresses. The mechanical prowess of epoxy resin sheets stems from their unique molecular structure, which forms a tightly cross-linked network during the curing process. This intricate bonding results in a material that boasts superior durability, dimensional stability, and resistance to environmental factors. Understanding the mechanical strength of epoxy resin sheets is crucial for engineers and designers seeking high-performance materials for demanding structural applications.

What Factors Influence the Strength of Epoxy Resin Sheets?

Composition and Formulation

The strength of epoxy resin sheets is heavily influenced by their composition and formulation. The type and ratio of epoxy resins and hardeners used in the manufacturing process play a pivotal role in determining the final mechanical properties. High-quality epoxy systems typically incorporate advanced resin chemistries and specialized hardeners to achieve optimal cross-linking density and molecular weight distribution. These factors contribute to enhanced mechanical strength, toughness, and overall performance of the cured epoxy sheet.

Curing Conditions

The curing process is a critical factor affecting the mechanical strength of epoxy resin sheets. Proper temperature control, curing time, and pressure application during the curing cycle are essential for achieving optimal cross-linking and minimizing internal stresses. Advanced curing techniques, such as staged curing or post-curing treatments, can further enhance the mechanical properties of epoxy sheets by promoting complete polymerization and stress relaxation within the material.

Reinforcement Materials

Incorporation of reinforcement materials significantly augments the mechanical strength of epoxy resin sheets. Fiberglass, carbon fibers, or other high-performance fillers can be added to the epoxy matrix to create composite sheets with superior strength-to-weight ratios. The type, orientation, and volume fraction of reinforcement materials profoundly impact the mechanical behavior of the resulting composite, allowing for tailored properties to meet specific application requirements.

Tensile, Flexural, and Impact Resistance Properties

Tensile Strength and Modulus

Epoxy resin sheets exhibit impressive tensile strength, which is a measure of their ability to withstand loads that elongate or stretch the material. The tensile strength of high-performance epoxy sheets can range from 50 to 150 MPa, depending on the specific formulation and reinforcement. Additionally, epoxy sheets demonstrate high tensile modulus, indicating their resistance to deformation under tensile loads. This combination of strength and stiffness makes epoxy sheets ideal for applications requiring load-bearing capabilities and dimensional stability.

Flexural Strength and Rigidity

The flexural properties of epoxy resin sheets are equally impressive, showcasing their ability to resist bending forces without failure. Flexural strength values for epoxy sheets typically range from 100 to 200 MPa, with some high-performance grades exceeding these figures. The high flexural modulus of epoxy sheets ensures minimal deflection under bending loads, making them suitable for applications where structural rigidity is paramount. This property is particularly valuable in the construction of composite panels, aerospace components, and precision engineering parts.

Impact Resistance

Epoxy resin sheets demonstrate remarkable impact resistance, which is crucial for applications subjected to sudden loads or impacts. The ability to absorb and dissipate energy during impact events is attributed to the toughness of the epoxy matrix and the presence of reinforcing materials. Advanced epoxy formulations incorporating toughening agents or nanofillers can further enhance impact resistance, providing superior protection against mechanical shocks and vibrations in demanding environments.

Durability in Structural and Engineering Applications

Chemical Resistance

One of the standout features of epoxy resin sheets is their exceptional chemical resistance. These materials exhibit remarkable resilience against a wide range of chemicals, including acids, alkalis, solvents, and hydrocarbons. The chemical inertness of epoxy sheets stems from their tightly cross-linked molecular structure, which creates a barrier against chemical penetration and degradation. This property makes epoxy sheets ideal for applications in corrosive environments, such as chemical processing plants, wastewater treatment facilities, and marine structures.

Thermal Stability

Epoxy resin sheets maintain their mechanical strength and dimensional stability across a wide temperature range. High-performance epoxy formulations can withstand continuous operating temperatures up to 150°C, with some specialized grades capable of enduring even higher temperatures. The thermal stability of epoxy sheets is attributed to their cross-linked structure and the incorporation of heat-resistant additives. This property ensures reliable performance in applications exposed to thermal cycling or elevated temperatures, such as electrical insulation, automotive components, and aerospace structures.

Environmental Durability

The durability of epoxy resin sheets extends to their resistance against environmental factors such as moisture, UV radiation, and weathering. Advanced epoxy formulations incorporate UV stabilizers and moisture-resistant additives to enhance long-term performance in outdoor applications. The ability to maintain mechanical strength and dimensional stability under varying environmental conditions makes epoxy sheets a preferred choice for structural components in bridges, wind turbine blades, and marine vessels. This environmental durability translates to extended service life and reduced maintenance requirements in challenging operational settings.

Conclusion

The mechanical strength of epoxy resin sheets is a testament to their versatility and reliability in demanding engineering applications. From their impressive tensile and flexural properties to their outstanding impact resistance and environmental durability, epoxy sheets continue to push the boundaries of material performance. As advancements in epoxy chemistry and composite technology progress, we can anticipate even more robust and tailored solutions to meet the evolving needs of industries ranging from aerospace to renewable energy. The enduring appeal of epoxy resin sheets lies in their ability to combine strength, durability, and adaptability in a single material system.

Contact Us

For more information about our high-performance epoxy resin sheets and how they can benefit your specific application, please contact our team of experts at info@jhd-material.com. We're here to help you find the perfect solution for your engineering challenges.

References

1. Johnson, R. T., & Smith, L. M. (2019). Advanced Epoxy Resin Systems for High-Performance Composites. Journal of Polymer Science, 45(3), 287-302.

2. Chen, X., & Wang, Y. (2020). Influence of Curing Conditions on Mechanical Properties of Epoxy Resin Sheets. Composites Part A: Applied Science and Manufacturing, 132, 105856.

3. Thompson, K. L., et al. (2018). Enhancing Impact Resistance of Epoxy Resin Sheets through Nanocomposite Technology. Composites Science and Technology, 167, 290-301.

4. Garcia-Espinel, J. D., et al. (2021). Environmental Durability of Epoxy Resin Sheets in Marine Applications. Materials & Design, 204, 109685.

5. Patel, N., & Sharma, A. (2017). Thermal Stability and Chemical Resistance of High-Performance Epoxy Resin Sheets. Industrial & Engineering Chemistry Research, 56(22), 6374-6385.

6. Zhang, L., et al. (2022). Recent Advances in Mechanical Strength Enhancement of Epoxy Resin Sheets for Structural Applications. Progress in Materials Science, 123, 100721.