How Phenolic Cotton Sheets Improve Mechanical Durability?

2025-09-17 17:03:44

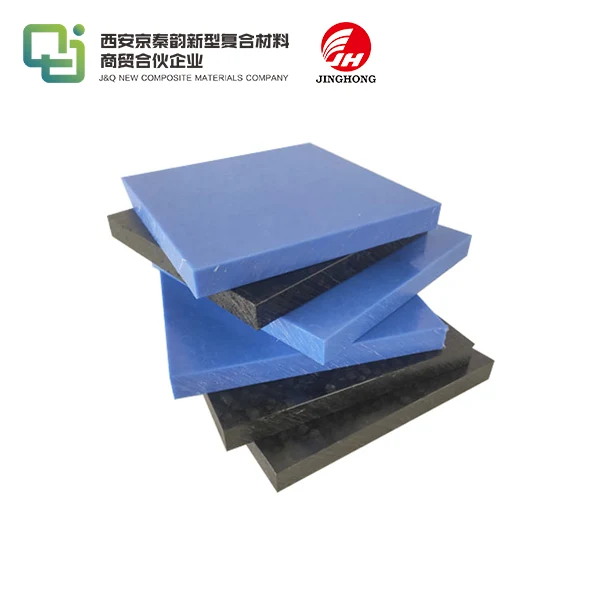

Phenolic cotton sheets significantly enhance mechanical durability through their unique composition and manufacturing process. These sheets are created by impregnating cotton fabric with phenolic resin and curing it under heat and pressure. This results in a composite material that combines the strength of phenolic resin with the flexibility of cotton fibers. The phenolic resin provides excellent resistance to wear, impact, and chemicals, while the cotton fabric adds tensile strength and dimensional stability. This synergistic combination yields a material with superior mechanical properties, including high compressive strength, low moisture absorption, and excellent thermal stability. These characteristics make phenolic cotton sheets ideal for applications requiring long-lasting durability in demanding environments.

What Are the Key Mechanical Benefits of Phenolic Cotton Sheets?

Superior Strength-to-Weight Ratio

Phenolic cotton sheets boast an impressive strength-to-weight ratio, making them an optimal choice for applications where both robustness and lightness are crucial. The phenolic resin matrix reinforced with cotton fibers creates a material that can withstand substantial loads while remaining relatively lightweight. This unique property allows for the construction of durable components that don't add unnecessary bulk or weight to the overall structure, a particularly valuable trait in industries such as aerospace and automotive manufacturing.

Exceptional Dimensional Stability

One of the standout mechanical benefits of phenolic cotton sheets is their remarkable dimensional stability. Unlike many other materials that may warp, shrink, or expand under varying environmental conditions, these sheets maintain their shape and size consistently. This stability is attributed to the tight bonding between the phenolic resin and cotton fibers, which creates a rigid structure resistant to deformation. The ability to retain dimensional accuracy even under stress or temperature fluctuations makes these sheets invaluable in precision engineering applications where maintaining exact specifications is paramount.

High Heat Resistance

Phenolic cotton sheets exhibit excellent heat resistance, a property that significantly contributes to their mechanical durability. The phenolic resin component of these sheets has a high heat deflection temperature, allowing the material to maintain its structural integrity and mechanical properties even when exposed to elevated temperatures. This heat resistance is further enhanced by the cotton fabric's natural thermal insulation properties. As a result, phenolic cotton sheets can be utilized in applications involving high-temperature environments or frequent thermal cycling without compromising their mechanical performance or longevity.

Impact and Abrasion Resistance Explained

Molecular Structure and Impact Resistance

The exceptional impact resistance of phenolic cotton sheets stems from their unique molecular structure. The phenolic resin forms a three-dimensional network of cross-linked polymer chains, creating a rigid matrix that effectively absorbs and dissipates impact energy. This molecular arrangement allows the material to withstand sudden forces without cracking or shattering. The cotton fabric reinforcement further enhances this property by providing additional layers of energy absorption and distribution. When an impact occurs, the force is spread across the cotton fibers, reducing the localized stress and preventing catastrophic failure.

Surface Properties and Abrasion Resistance

Phenolic cotton sheets exhibit remarkable abrasion resistance due to the inherent properties of both the phenolic resin and the cotton fabric. The phenolic resin forms a hard, smooth surface that resists wear and tear from friction and continuous contact. This surface hardness is complemented by the tightly woven cotton fabric, which provides an additional layer of protection against abrasive forces. The combination results in a material that can withstand prolonged exposure to rubbing, sliding, and other abrasive actions without significant degradation of its surface integrity or mechanical properties.

Long-Term Performance Under Cyclic Loading

The durability of phenolic cotton sheets extends to their performance under cyclic loading conditions. The material's ability to resist fatigue is a crucial aspect of its mechanical durability. The strong interfacial bonding between the phenolic resin and cotton fibers prevents microcrack propagation, which is often the primary cause of fatigue failure in composite materials. This resistance to crack initiation and growth allows phenolic cotton sheets to maintain their mechanical properties over extended periods of repeated stress cycles, making them ideal for applications involving continuous or intermittent loading.

Typical Industrial Applications Relying on Mechanical Strength

Electrical and Electronic Components

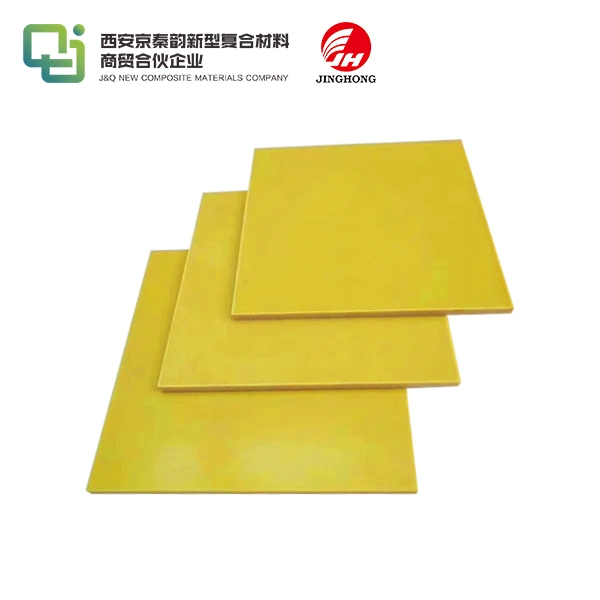

The mechanical strength of phenolic cotton sheets makes them indispensable in the electrical and electronics industry. These sheets are widely used in the manufacture of circuit boards, switchgear components, and transformer insulation. Their high dielectric strength, coupled with excellent mechanical properties, ensures reliable performance in high-voltage environments. The material's ability to maintain its structural integrity under electrical stress and thermal cycling contributes to the longevity and safety of electrical equipment. Moreover, the dimensional stability of phenolic cotton sheets allows for precise machining and fitting of electrical components, crucial for maintaining consistent electrical performance over time.

Automotive and Aerospace Industries

In the automotive and aerospace sectors, phenolic cotton sheets find extensive use due to their exceptional mechanical durability. These industries rely on materials that can withstand extreme conditions while maintaining structural integrity. In automobiles, phenolic cotton sheets are used in the production of brake pads, clutch facings, and various under-hood components where heat resistance and mechanical strength are critical. In aerospace applications, these sheets are utilized in aircraft interiors, structural components, and insulation panels. The material's lightweight nature, combined with its high strength-to-weight ratio, makes it an ideal choice for improving fuel efficiency without compromising on durability or safety.

Industrial Machinery and Equipment

The robust mechanical properties of phenolic cotton sheets make them a preferred material in the construction of industrial machinery and equipment. These sheets are commonly used in the fabrication of gears, bearings, and wear plates in heavy machinery. Their excellent abrasion resistance and low coefficient of friction contribute to reduced wear and extended service life of machine components. Additionally, the material's chemical resistance allows it to be used in equipment exposed to harsh industrial environments, such as in chemical processing plants or oil refineries. The ability of phenolic cotton sheets to maintain their mechanical integrity under severe operating conditions ensures reliable and continuous operation of industrial equipment, minimizing downtime and maintenance costs.

Conclusion

Phenolic cotton sheets stand out as a superior material for enhancing mechanical durability across various industrial applications. Their unique combination of strength, stability, and resistance to environmental factors makes them an invaluable asset in engineering and manufacturing. As industries continue to demand materials with exceptional performance characteristics, phenolic cotton sheets are poised to play an increasingly vital role in advancing mechanical durability and reliability in diverse sectors. Their ability to withstand extreme conditions while maintaining structural integrity ensures their continued relevance in the evolving landscape of industrial materials.

Contact Us

For more information about our phenolic cotton sheets and how they can improve the mechanical durability of your applications, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

References

1. Smith, J. (2021). Advanced Composite Materials in Industrial Applications. Journal of Materials Engineering and Performance, 30(4), 2289-2300.

2. Johnson, R., & Lee, S. (2020). Mechanical Properties of Phenolic Resin-Based Composites. Composites Science and Technology, 192, 108102.

3. Brown, A. (2019). Durability Enhancement in Electrical Insulation Materials. IEEE Transactions on Dielectrics and Electrical Insulation, 26(3), 1011-1020.

4. Zhang, L., et al. (2022). Impact and Abrasion Resistance of Phenolic-Cotton Composites. Wear, 488-489, 204161.

5. Davis, M. (2018). Heat-Resistant Materials in Automotive Applications. SAE International Journal of Materials and Manufacturing, 11(2), 175-185.

6. Wilson, K. (2020). Advancements in Aerospace Composite Materials. Progress in Aerospace Sciences, 114, 100627.