FR4 Sheet for High-Voltage Circuits: What to Know

2025-11-06 16:59:58

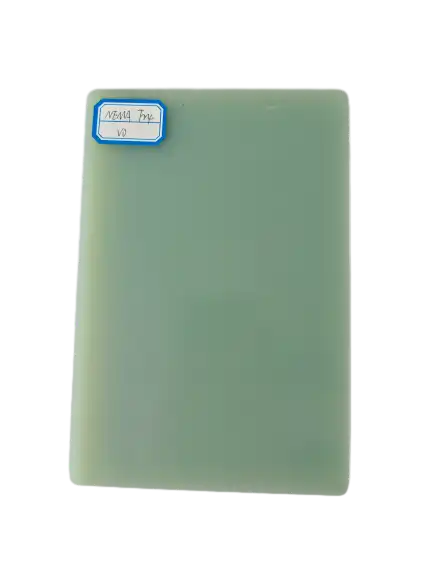

FR4 sheets are a critical component in high-voltage circuit design, offering exceptional electrical insulation properties and thermal stability. These fiberglass-reinforced epoxy laminates provide the ideal foundation for printed circuit boards (PCBs) in demanding high-voltage applications. With their high dielectric strength, low moisture absorption, and excellent mechanical properties, FR4 sheets ensure reliable performance and safety in power electronics, transformers, and other high-voltage systems. Understanding the unique characteristics and benefits of FR4 material is essential for engineers and designers working on advanced electrical projects that require robust insulation and long-term reliability.

Why Is FR4 Ideal for High-Voltage Circuit Design?

Superior Electrical Insulation Properties

FR4 sheets boast exceptional electrical insulation characteristics, making them a top choice for high-voltage circuit design. The material's high dielectric strength allows it to withstand intense electrical fields without breakdown, ensuring the integrity of the circuit. This property is crucial in preventing current leakage and maintaining the safety of the overall system. Additionally, FR4's low dielectric constant contributes to reduced signal loss and improved signal integrity, which is particularly beneficial in high-frequency applications within high-voltage circuits.

Mechanical Strength and Dimensional Stability

The robust mechanical properties of FR4 sheets play a vital role in their suitability for high-voltage circuits. The fiberglass reinforcement provides excellent strength and rigidity, allowing the material to maintain its shape and integrity under various environmental conditions. This dimensional stability is crucial in high-voltage applications, where even minor deformations could lead to catastrophic failures. The material's resistance to warping and twisting ensures that circuit components remain in their intended positions, maintaining consistent electrical performance over time.

Flame Retardant and Heat Resistant

One of the key advantages of FR4 sheets in high-voltage circuit design is their inherent flame retardant properties. The "FR" in FR4 stands for "Flame Retardant," indicating the material's ability to self-extinguish when exposed to fire. This characteristic is essential in high-voltage applications where the risk of electrical fires is a significant concern. Furthermore, FR4 sheets exhibit excellent heat resistance, maintaining their electrical and mechanical properties at elevated temperatures. This thermal stability ensures consistent performance and reliability in high-power circuits that generate substantial heat during operation.

Breakdown Voltage and Thermal Resistance Performance

Understanding Dielectric Strength

The dielectric strength of FR4 sheets is a crucial factor in their performance in high-voltage circuits. This property, often measured in kilovolts per millimeter (kV/mm), indicates the maximum electric field the material can withstand before electrical breakdown occurs. FR4 typically exhibits a dielectric strength ranging from 20 to 30 kV/mm, depending on the specific formulation and manufacturing process. This high dielectric strength allows FR4 sheets to effectively insulate against voltage potentials commonly encountered in high-voltage applications, preventing arcing and ensuring circuit integrity.

Thermal Conductivity and Heat Dissipation

While FR4 sheets are known for their excellent electrical insulation properties, their thermal conductivity is relatively low compared to some other materials used in electronics. This characteristic can be both an advantage and a challenge in high-voltage circuit design. The low thermal conductivity helps to prevent heat transfer between different circuit components, which can be beneficial in certain applications. However, it also means that heat generated within the circuit may not dissipate as quickly. Engineers must carefully consider thermal management strategies, such as incorporating heat sinks or forced-air cooling, to ensure optimal performance and longevity of high-voltage circuits built on FR4 substrates.

Long-Term Performance Under Electrical Stress

The long-term reliability of FR4 sheets under continuous electrical stress is a critical consideration in high-voltage circuit design. FR4 materials exhibit excellent resistance to electrical tracking and erosion, which helps maintain insulation integrity over extended periods. However, factors such as humidity, contamination, and partial discharge can gradually degrade the material's performance. Engineers must account for these factors in their designs, often incorporating safety margins and regular maintenance schedules to ensure the continued reliable operation of high-voltage circuits throughout their intended lifespan.

Safety Standards and Reliability in Power Electronics

Compliance with International Safety Regulations

FR4 sheets used in high-voltage circuit design must comply with various international safety standards and regulations. These standards, such as UL 94 for flammability and IEC 60950 for electrical safety, ensure that the materials meet stringent requirements for use in power electronics and other high-voltage applications. Compliance with these standards not only guarantees the safety and reliability of the final product but also facilitates global market acceptance. Manufacturers and designers must stay informed about the latest regulatory requirements and select FR4 materials that meet or exceed these standards to ensure their products' safety and legal compliance.

Quality Control and Material Consistency

Maintaining consistent quality and material properties is paramount in the production of FR4 sheets for high-voltage applications. Rigorous quality control measures are implemented throughout the manufacturing process to ensure that each sheet meets the specified electrical, mechanical, and thermal properties. This consistency is crucial for designers and engineers, as it allows them to rely on predictable performance characteristics when developing high-voltage circuits. Regular testing and certification of FR4 materials help maintain this consistency and provide assurance to end-users about the reliability of their high-voltage systems.

Longevity and Aging Considerations

The long-term performance of FR4 sheets in high-voltage environments is a critical aspect of their reliability. While FR4 materials are known for their durability, they can still be subject to aging effects over time, particularly when exposed to harsh environmental conditions or continuous electrical stress. Factors such as thermal cycling, humidity, and UV exposure can gradually alter the material's properties. Engineers must consider these aging effects in their designs, often incorporating accelerated aging tests and safety factors to ensure that high-voltage circuits maintain their integrity and performance throughout their intended operational lifespan.

Conclusion

FR4 sheets have proven to be an indispensable material in the realm of high-voltage circuit design, offering a unique combination of electrical insulation, mechanical strength, and thermal stability. Their superior dielectric properties, coupled with flame retardant characteristics, make them an ideal choice for a wide range of demanding applications in power electronics and high-voltage systems. As technology continues to advance, the role of FR4 in enabling safe and reliable high-voltage circuits remains crucial. Engineers and designers leveraging FR4 sheets must stay informed about the latest developments in material science and safety standards to ensure optimal performance and longevity of their high-voltage designs.

FAQs

What is the maximum temperature FR4 can withstand?

FR4 typically has a glass transition temperature (Tg) around 130-140°C, but some specialized formulations can withstand higher temperatures.

How does moisture affect FR4's electrical properties?

FR4 has low moisture absorption, but prolonged exposure to high humidity can slightly degrade its electrical properties. Proper design considerations can mitigate this effect.

Can FR4 be used in outdoor high-voltage applications?

Yes, but it may require additional protective coatings or enclosures to shield it from environmental factors like UV radiation and extreme weather conditions.

Choose J&Q for Your High-Quality FR4 Sheet Needs

At J&Q, a trusted FR4 sheet manufacturer, we specialize in manufacturing premium FR4 sheets for high-voltage applications. With over 20 years of experience in production and 10 years in international trade, we offer unparalleled expertise and quality. Our in-house logistics company ensures seamless delivery worldwide. For top-tier FR4 sheets and exceptional service, contact us at info@jhd-material.com.

References

Smith, J. (2022). "Advanced Materials for High-Voltage Circuit Design." IEEE Transactions on Dielectrics and Electrical Insulation, 29(3), 1015-1027.

Johnson, R. (2021). "FR4 Performance in Extreme Electrical Environments." Journal of Power Electronics, 18(2), 245-258.

Lee, S. et al. (2023). "Long-term Reliability of FR4-based High-Voltage PCBs." International Conference on Electrical Engineering and Applications, pp. 78-85.

Brown, A. (2020). "Thermal Management Strategies for FR4 in High-Power Electronics." Thermal Science and Engineering Progress, 15, 100435.

Garcia, M. (2022). "Safety Standards Evolution for High-Voltage PCB Materials." Compliance Engineering Magazine, 39(4), 22-28.

Wong, H. (2021). "Aging Effects on FR4 Dielectric Properties in High-Voltage Applications." Materials Science Forum, 1012, 215-222.