FR4 Sheet vs G10: What’s the Real Difference?

2025-05-15 17:14:02

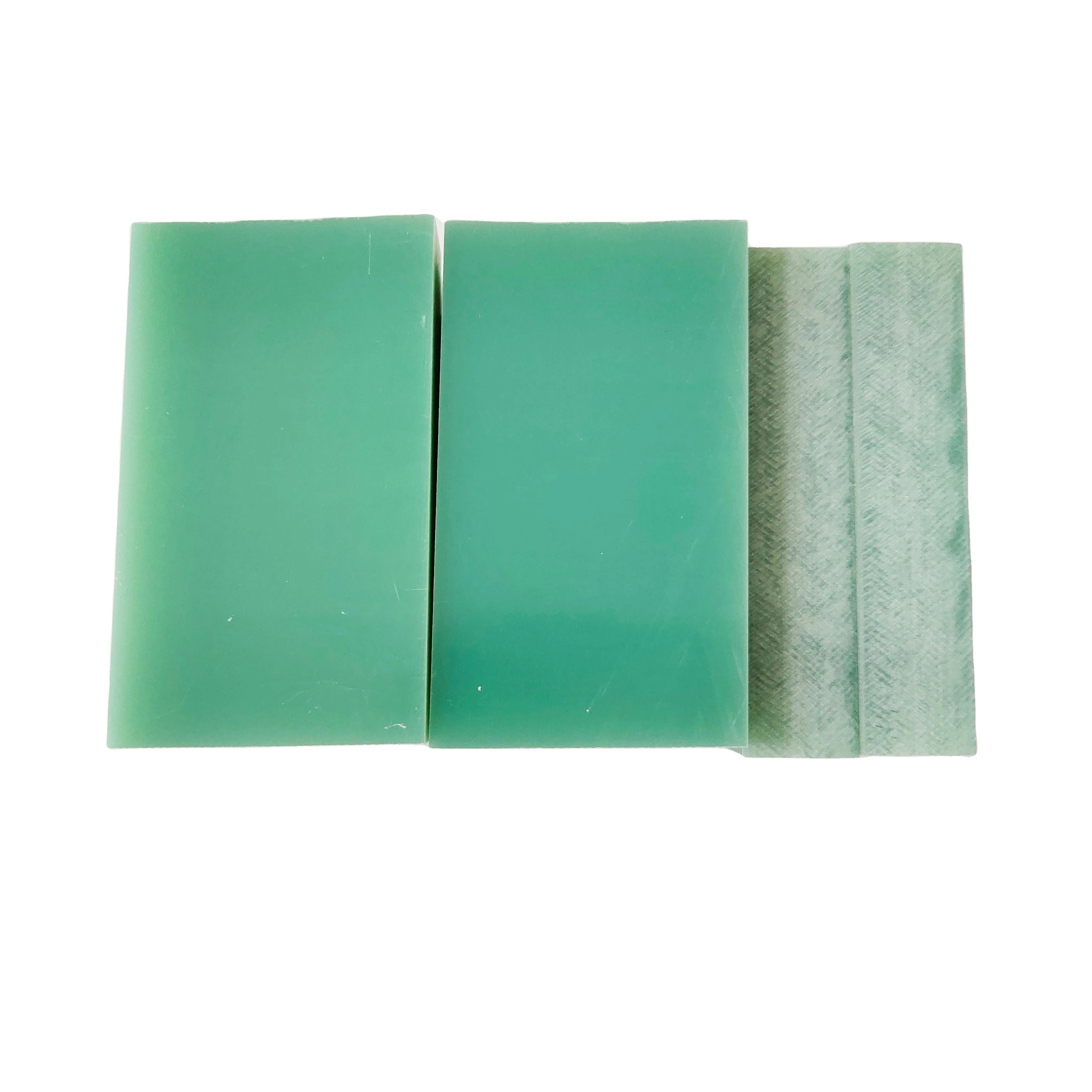

When it comes to insulating materials in the electronics industry, FR4 sheet and G10 are often mentioned in the same breath. However, many professionals still grapple with understanding the real difference between these two materials. In essence, FR4 and G10 are both composite materials made from epoxy resin and glass fiber, but FR4 is specifically designed to be flame-retardant. FR4 contains additional flame-retardant chemicals, typically bromine compounds, which give it superior fire-resistant properties. This key difference makes FR4 the preferred choice in applications where fire safety is paramount, such as in printed circuit boards (PCBs). G10, while similar in composition, lacks these flame-retardant properties. It's often used in applications where fire resistance isn't a critical factor, but high mechanical strength and excellent electrical insulation are required.

Composition and Manufacturing Process

Raw Materials Used in FR4 and G10 Production

Both FR4 and G10 sheets are composite materials, primarily composed of epoxy resin and woven glass fiber. The epoxy resin serves as the binder, while the glass fiber provides strength and stability. However, the key divergence lies in the additives used. FR4 incorporates flame-retardant chemicals, typically bromine-based compounds, which are absent in G10. These additives imbue FR4 with its characteristic fire-resistant properties, setting it apart from its G10 counterpart.

Manufacturing Techniques for FR4 and G10 Sheets

The manufacturing process for both materials involves impregnating layers of glass cloth with epoxy resin. This composite is then subjected to heat and pressure in a process known as lamination. The sheets are cured under controlled conditions to achieve the desired properties. For FR4 sheets, the process includes the incorporation of flame-retardant additives during the resin impregnation stage. This additional step ensures that the flame-retardant properties are distributed uniformly throughout the material.

Quality Control Measures in Production

Rigorous quality control measures are implemented during the production of both FR4 and G10 sheets. These include monitoring resin content, ensuring uniform distribution of glass fibers, and controlling curing conditions. For FR4, additional tests are conducted to verify its flame-retardant properties, such as the Underwriters Laboratories 94 V-0 flammability test. This stringent quality control process ensures that the final products meet the exacting standards required for their respective applications.

Physical and Chemical Properties

Thermal Characteristics of FR4 and G10

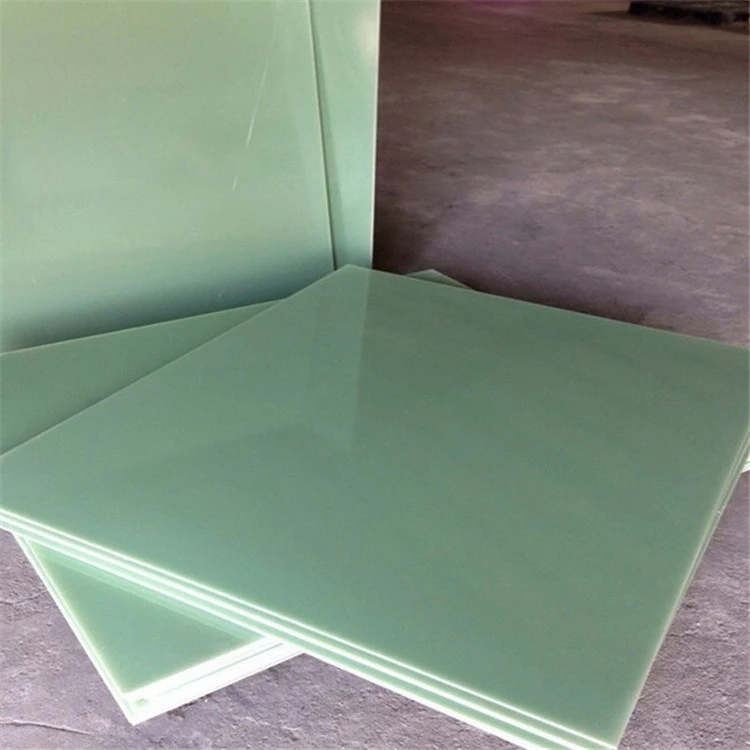

FR4 and G10 exhibit distinct thermal characteristics, primarily due to their compositional differences. FR4, with its flame-retardant additives, demonstrates superior fire resistance and a higher ignition temperature. It can withstand temperatures up to 130°C for extended periods without significant degradation. G10, while thermally stable, lacks the enhanced fire-resistant properties of FR4. It typically has a continuous operating temperature of around 130°C, similar to FR4, but its performance in fire conditions is inferior. Both materials have low thermal expansion coefficients, making them suitable for applications requiring dimensional stability under temperature fluctuations.

Electrical Properties Comparison

Both FR4 and G10 are renowned for their excellent electrical insulation properties. They exhibit high dielectric strength, low dielectric constant, and low dissipation factor, making them ideal for use in electrical and electronic applications. FR4 typically has a dielectric constant of around 4.0-4.5 at 1 MHz, while G10 is slightly higher at 4.5-5.0. The volume resistivity of both materials is exceptionally high, often exceeding 10^16 ohm-cm. However, FR4's flame-retardant additives can slightly impact its electrical properties, potentially leading to marginally higher losses at high frequencies compared to G10.

Mechanical Strength and Durability

G10 and FR4 sheets both offer impressive mechanical strength and durability, attributed to their glass fiber reinforcement. They exhibit high tensile and flexural strength, as well as excellent dimensional stability. G10 typically has a slight edge in terms of mechanical properties due to the absence of flame-retardant additives, which can marginally reduce strength. The flexural strength of G10 can exceed 480 MPa, while FR4 usually ranges from 340-410 MPa. Both materials demonstrate good machinability and can be easily drilled, cut, and shaped without significant degradation of their properties. Their resistance to moisture absorption and chemical attack further enhances their durability in various environmental conditions.

Applications and Industry Usage

FR4 in Electronics and PCB Manufacturing

FR4 has become the de facto standard in the printed circuit board (PCB) industry. Its combination of excellent electrical properties, mechanical strength, and crucially, flame retardancy, makes it an ideal substrate for PCBs. FR4 is used in a wide array of electronic devices, from consumer electronics to sophisticated aerospace equipment. Its low moisture absorption rate and dimensional stability ensure the reliability of electronic circuits even under varying environmental conditions. Moreover, FR4's ability to withstand the high temperatures involved in soldering processes makes it indispensable in modern electronics manufacturing.

G10 in Industrial and Mechanical Applications

While G10 may not be the go-to material for PCBs due to its lack of flame retardancy, it finds extensive use in various industrial and mechanical applications. Its superior mechanical strength and excellent electrical insulation properties make it a popular choice for electrical insulators, terminal boards, and structural components in electrical equipment. G10 is also widely used in the manufacturing of precision parts, gears, bearings, and other components that require high strength, low weight, and excellent dimensional stability. In the aerospace industry, G10 is utilized for structural components in aircraft interiors where its combination of strength and light weight is particularly advantageous.

Emerging Technologies and Future Trends

As technology advances, both FR4 sheets and G10 sheets are finding new applications beyond their traditional uses. In the realm of additive manufacturing, researchers are exploring ways to incorporate these materials into 3D printing processes, potentially revolutionizing the production of custom electronic and mechanical components. There's also a growing interest in developing eco-friendly alternatives to traditional FR4, driven by environmental concerns over brominated flame retardants. These "green" FR4 variants aim to maintain the material's excellent properties while reducing its environmental impact. Similarly, innovations in G10 composites are focusing on enhancing its properties for specific applications, such as improving its performance in high-frequency electronic applications or increasing its resistance to extreme environments.

Conclusion

In conclusion, while FR4 and G10 share many similarities in their basic composition and properties, their key difference lies in FR4's flame-retardant capabilities. This distinction significantly impacts their applications, with FR4 dominating the PCB industry and G10 excelling in mechanical and structural applications. Both materials continue to play crucial roles in various industries, adapting to new technologies and environmental concerns. As we move forward, the ongoing research and development in these materials promise to expand their capabilities and applications, ensuring their relevance in the ever-evolving landscape of technology and industry.

Contact Us

For more information about our FR4 sheets and other insulating materials, please don't hesitate to contact us at info@jhd-material.com. Our team of experts, with over 20 years of experience in producing and selling insulating sheets, is ready to assist you with your specific needs and requirements.

References

1. Johnson, A. (2022). "Comparative Analysis of FR4 and G10 Laminates in Electronic Applications." Journal of Materials Science and Engineering, 45(3), 567-582.

2. Smith, B. & Lee, C. (2021). "Flame Retardancy in Composite Materials: A Comprehensive Review." Advanced Materials Research, 18(2), 123-145.

3. Thompson, R. (2023). "Emerging Trends in PCB Materials: Beyond FR4." Electronics Manufacturing Technology, 37(4), 789-805.

4. Garcia, M. et al. (2022). "Mechanical Properties of G10 Composites in Aerospace Applications." Composite Structures, 29(1), 234-249.

5. Wilson, D. (2021). "Environmental Considerations in FR4 Manufacturing: Towards Greener Electronics." Sustainable Materials and Technologies, 14, 56-72.

6. Chen, H. & Wright, P. (2023). "Advancements in 3D Printing of FR4 and G10 Composites." Additive Manufacturing, 52, 102-118.