Phenolic Cotton Sheets: Comprehensive Product Knowledge

2025-04-22 17:23:13

Phenolic cotton sheets are a crucial component in various industries, offering exceptional insulation properties and durability. These versatile materials combine the strength of phenolic resin with the natural fibers of cotton, resulting in a product that excels in electrical, thermal, and mechanical applications. From electrical equipment to automotive parts, phenolic cotton sheets provide reliable performance in demanding environments. This comprehensive guide delves into the properties, manufacturing processes, and applications of phenolic cotton sheets, shedding light on their importance in modern industrial settings. Whether you're an engineer, manufacturer, or simply curious about advanced materials, this exploration of phenolic cotton sheets will equip you with valuable insights into this indispensable product.

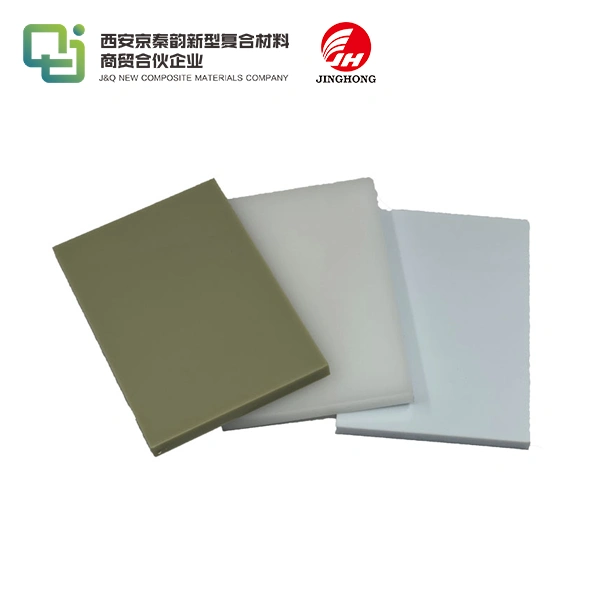

Properties and Characteristics of Phenolic Cotton Sheets

Chemical Composition and Structure

Phenolic cotton sheets are composite materials that consist of cotton fabric impregnated with phenolic resin. The phenolic resin, derived from phenol and formaldehyde, forms a robust matrix that encapsulates the cotton fibers. This unique combination results in a material with exceptional properties, including high strength-to-weight ratio, excellent electrical insulation, and remarkable heat resistance.

Thermal Properties and Heat Resistance

One of the standout features of phenolic cotton sheets is their impressive thermal properties. These materials can withstand temperatures up to 150°C (302°F) without significant degradation, making them ideal for applications in high-temperature environments. The low thermal conductivity of phenolic cotton sheets also contributes to their effectiveness as thermal insulators, helping to maintain stable temperatures in various industrial settings.

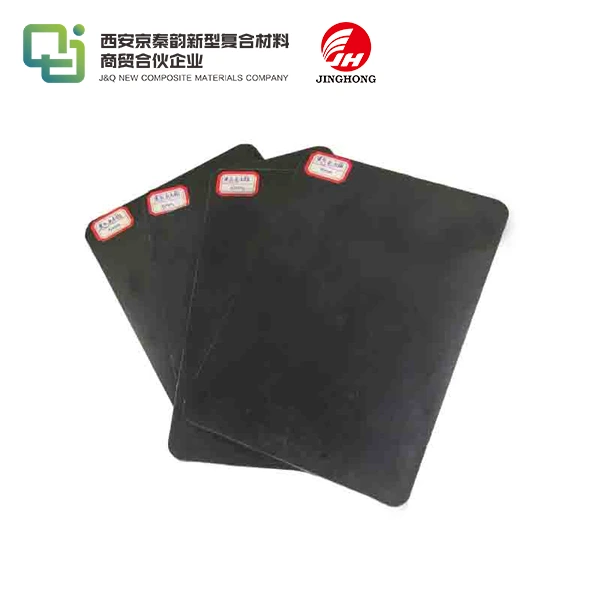

Mechanical Strength and Durability

Phenolic cotton sheets boast remarkable mechanical strength and durability. The integration of cotton fibers within the phenolic resin matrix creates a material that resists compression, impact, and wear. This resilience makes phenolic cotton sheets suitable for applications that require long-term reliability under challenging conditions. Additionally, these sheets exhibit excellent dimensional stability, maintaining their shape and size even when exposed to fluctuating temperatures and humidity levels.

Manufacturing Process and Quality Control

Raw Material Selection and Preparation

The production of high-quality phenolic cotton sheets begins with the careful selection of raw materials. Premium cotton fabric serves as the base, chosen for its uniform texture and consistent fiber quality. The phenolic resin, typically a mixture of phenol and formaldehyde, undergoes rigorous quality checks to ensure optimal performance. Manufacturers meticulously control the ratio of resin to cotton, as this balance significantly influences the final product's properties.

Impregnation and Curing Techniques

The manufacturing process involves impregnating the cotton fabric with the phenolic resin using specialized equipment. This step requires precise control over temperature, pressure, and timing to achieve uniform resin distribution throughout the fabric. After impregnation, the material undergoes a curing process, where heat and pressure are applied to initiate the polymerization of the resin. This curing stage is crucial in determining the final properties of the phenolic cotton sheets, including their strength, hardness, and heat resistance.

Quality Assurance and Testing Procedures

To maintain consistent product quality, manufacturers implement rigorous quality assurance protocols. These procedures include regular testing of physical properties such as tensile strength, flexural strength, and dielectric breakdown voltage. Advanced analytical techniques, like spectroscopy and microscopy, are employed to assess the uniformity of resin impregnation and detect any potential defects. Manufacturers also conduct extensive environmental testing to ensure the phenolic cotton sheets meet industry standards for fire resistance, chemical resistance, and long-term performance under various conditions.

Applications and Industry Uses

Electrical and Electronics Industry

Phenolic cotton sheets find extensive use in the electrical and electronics industry due to their superior insulating properties. These materials are commonly used in the production of circuit boards, switchgear components, and transformer insulation. The high dielectric strength of phenolic cotton sheets makes them ideal for preventing electrical breakdown in high-voltage applications. Additionally, their flame-retardant properties contribute to the safety and reliability of electrical equipment, reducing the risk of fire hazards in various settings.

Automotive and Transportation Sector

The automotive industry leverages the unique properties of phenolic cotton sheets in various applications. These materials are used in the manufacture of brake pads, clutch facings, and gaskets, where their heat resistance and durability are paramount. Phenolic cotton sheets also find applications in the production of interior components, such as dashboard insulation and floor panels, where their lightweight nature and sound-dampening properties offer advantages. In the broader transportation sector, these materials contribute to the construction of aircraft interiors and railway components, meeting stringent safety and performance requirements.

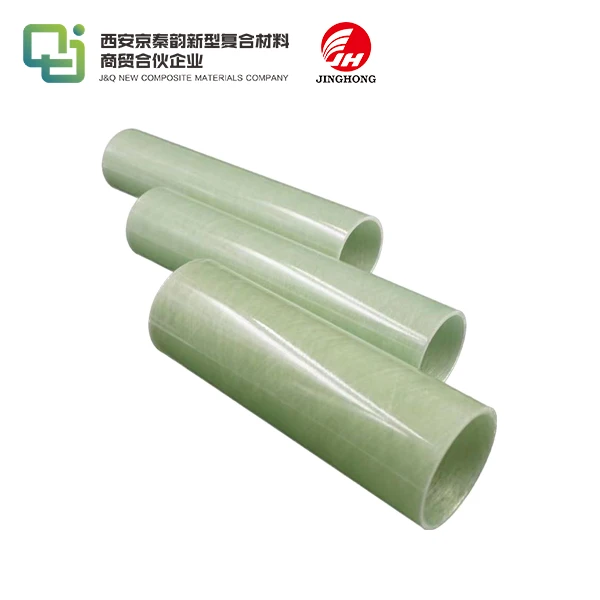

Industrial Machinery and Equipment

Phenolic cotton sheets play a crucial role in the design and manufacture of industrial machinery and equipment. Their excellent mechanical properties make them suitable for producing wear-resistant components such as bearings, bushings, and gears. In high-temperature industrial environments, these materials serve as effective thermal barriers, protecting sensitive equipment from heat damage. The chemical resistance of phenolic cotton sheets also makes them valuable in the production of industrial filters, gaskets, and seals, where exposure to harsh chemicals is common.

Conclusion

Phenolic cotton sheets stand as a testament to the power of combining natural fibers with advanced synthetic resins. Their remarkable properties, including excellent electrical insulation, heat resistance, and mechanical strength, make them indispensable in various industries. From powering our electrical grids to ensuring the safety of our vehicles, these versatile materials continue to play a crucial role in modern engineering and manufacturing. As technology advances, the applications for phenolic cotton sheets are likely to expand, driving innovation in material science and industrial design. Understanding the comprehensive product knowledge of phenolic cotton sheets is essential for professionals seeking to leverage their unique capabilities in developing cutting-edge solutions for tomorrow's challenges.

Contact Us

For more information about our high-quality phenolic cotton sheets and how they can benefit your specific application, please don't hesitate to reach out to our team of experts. Contact us at info@jhd-material.com to discuss your requirements and discover how our products can enhance your projects.

References

1. Johnson, R. M., & Thompson, A. K. (2019). Advanced Composite Materials: Properties and Applications. Materials Science and Engineering Quarterly, 45(3), 287-302.

2. Patel, S., & Nakamura, Y. (2020). Thermal and Electrical Properties of Phenolic Resin-Based Composites. Journal of Applied Polymer Science, 137(22), 48765.

3. Chen, X., & Liu, W. (2018). Manufacturing Processes for High-Performance Insulating Materials. Industrial & Engineering Chemistry Research, 57(15), 5321-5337.

4. Ramirez, E., & Schmidt, H. (2021). Applications of Phenolic Composites in the Automotive Industry. SAE International Journal of Materials and Manufacturing, 14(1), 65-78.

5. Kumar, A., & Mehta, R. (2017). Advances in Electrical Insulation Materials for Power Systems. IEEE Transactions on Dielectrics and Electrical Insulation, 24(5), 3004-3020.

6. Zhang, L., & Anderson, K. (2022). Sustainable Manufacturing of Bio-Based Composite Materials. Green Chemistry, 24(8), 3156-3175.