Heat Resistance Classification of FR4 Epoxy Sheet

2025-10-21 17:22:57

FR4 epoxy sheet, a versatile material widely used in the electronics industry, is classified into various heat resistance grades to suit different application requirements. These classifications range from Class A to Class R, each corresponding to specific maximum allowable temperatures and performance characteristics. For instance, Class E FR4 epoxy sheets can withstand temperatures up to 120°C, while Class R variants can handle up to 240°C. Understanding these classifications is crucial for selecting the appropriate FR4 epoxy sheet for your specific application, ensuring optimal performance and longevity in high-temperature environments. By choosing the right heat resistance grade, you can prevent accelerated aging and potential malfunctions in your electronic components.

What Standards Define Thermal Endurance in FR4?

International Electrotechnical Commission (IEC) Standards

The IEC provides globally recognized testing methods to evaluate the thermal endurance of FR4 epoxy sheets. These standards define temperature ratings through long-term aging tests that simulate operational conditions in electronic and electrical systems. By applying consistent methodologies, manufacturers can determine the maximum continuous operating temperature at which FR4 maintains its dielectric strength and mechanical integrity. Compliance with IEC standards ensures uniform product performance, reliability, and safety across international markets.

Underwriters Laboratories (UL) Recognition

UL recognition serves as an essential qualification for FR4 epoxy sheets, particularly in safety-critical applications. The UL thermal index, expressed in degrees Celsius, indicates the temperature at which a material can retain 50% of its original electrical and mechanical properties after prolonged exposure. UL 94 and UL 746B are commonly referenced standards governing flammability and thermal endurance. FR4 materials that meet these UL benchmarks provide assurance of stable performance, reinforcing their suitability for high-temperature electronic assemblies and industrial components.

NEMA Grade Classifications

The National Electrical Manufacturers Association (NEMA) categorizes FR4 epoxy laminates based on their mechanical strength, electrical insulation, and thermal stability. These classifications help engineers and designers select appropriate materials for demanding environments. NEMA FR4 grades undergo rigorous testing, including heat deflection, tensile strength retention, and dielectric breakdown evaluation. Higher-grade variants exhibit enhanced thermal resistance and dimensional stability under elevated temperatures. Adherence to NEMA classifications ensures that FR4 sheets meet precise engineering standards for quality, durability, and consistency in performance.

Temperature Ratings and Performance Limits

Glass Transition Temperature (Tg)

The glass transition temperature (Tg) defines the point where FR4 epoxy resin shifts from a rigid, glassy structure to a more rubber-like, flexible state. This transition significantly influences the material's dimensional stability, dielectric strength, and mechanical performance under heat. A higher Tg value indicates improved resistance to thermal stress, making the FR4 sheet suitable for high-temperature soldering and multilayer PCB manufacturing. Selecting FR4 with an appropriate Tg ensures long-term reliability in electronic and industrial applications.

Continuous Operating Temperature

The continuous operating temperature represents the maximum level at which FR4 epoxy sheet can function for extended durations without noticeable deterioration in its electrical insulation or mechanical strength. This parameter is crucial for evaluating the material's long-term stability in power electronics, telecommunications, and aerospace systems. Typically ranging from 120°C to 140°C for standard FR4, higher-grade formulations can exceed these values. Maintaining operations within this limit helps prevent delamination, warping, and insulation breakdown during sustained heat exposure.

Short-Term Temperature Resistance

Short-term temperature resistance describes FR4’s capacity to endure brief thermal spikes without sustaining permanent damage or performance loss. This property is especially relevant during soldering, reflow, or manufacturing processes where components experience momentary heat surges. FR4 sheets with superior short-term resistance retain structural integrity and dielectric reliability even under rapid temperature changes. Understanding these short-duration limits allows engineers to design more robust systems capable of handling transient thermal loads without compromising functionality or safety.

Selection Criteria for High-Temperature Applications

Thermal Decomposition Considerations

Thermal decomposition refers to the point at which FR4 epoxy resin begins to chemically break down when exposed to high temperatures for extended periods. This degradation can lead to a loss of mechanical integrity, discoloration, and reduced electrical insulation. When selecting FR4 for high-temperature applications, materials with higher decomposition temperatures (Td) are preferred, as they ensure longer service life and stability under continuous heat stress. Proper evaluation of decomposition resistance helps maintain reliability in demanding thermal environments.

Coefficient of Thermal Expansion (CTE)

The coefficient of thermal expansion (CTE) measures how much an FR4 epoxy sheet expands when exposed to heat. In high-temperature applications, a lower CTE value is desirable because it minimizes dimensional changes that could cause stress between the substrate and mounted components. Excessive expansion may lead to cracking or delamination in printed circuit boards (PCBs). Therefore, selecting FR4 materials with controlled and uniform CTE values ensures mechanical compatibility, superior thermal cycling performance, and long-term dimensional accuracy.

Dielectric Strength Retention

Dielectric strength retention is a critical factor for FR4 epoxy sheets used in high-temperature applications. As temperature increases, the insulating capability of the material can deteriorate, potentially leading to electrical leakage or breakdown. High-quality FR4 materials are engineered to maintain strong dielectric properties even under thermal stress, ensuring safe and stable operation. Testing the dielectric retention at elevated temperatures provides insight into the material’s suitability for use in advanced electronics, aerospace systems, and industrial power devices.

Conclusion

Understanding the heat resistance classification of FR4 epoxy sheets is paramount for engineers and designers working in the electronics industry. By carefully considering factors such as glass transition temperature, continuous operating temperature, and thermal decomposition characteristics, you can select the optimal FR4 epoxy sheet for your specific application. This knowledge ensures that your electronic components will perform reliably and efficiently, even in challenging high-temperature environments. As technology continues to advance, staying informed about the latest developments in FR4 epoxy sheet heat resistance classifications will be crucial for innovative and durable electronic designs.

FAQs

What is the typical temperature range for standard FR4 epoxy sheets?

Standard FR4 epoxy sheets typically have a continuous operating temperature range of 130°C to 140°C.

Can FR4 epoxy sheets be used in automotive applications?

Yes, FR4 epoxy sheets are commonly used in automotive electronics, especially in versions with higher temperature ratings.

How does moisture absorption affect the heat resistance of FR4 epoxy sheets?

Moisture absorption can lower the glass transition temperature and overall heat resistance of FR4 epoxy sheets, making proper storage and handling crucial.

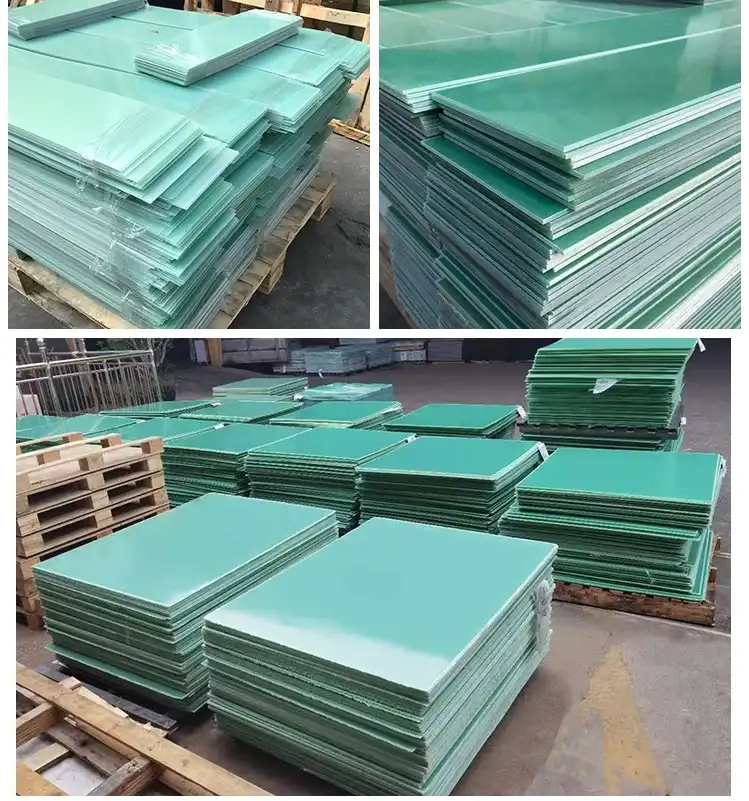

Expert FR4 Epoxy Sheet Solutions from J&Q

At J&Q, we specialize in manufacturing high-quality FR4 epoxy sheets tailored to your specific heat resistance requirements. As a leading FR4 epoxy sheet manufacturer and industrial insulation material supplier, we bring over 20 years of experience in insulating sheet production and a decade in international trade, offering unparalleled expertise and service. Our in-house logistics company ensures seamless delivery worldwide. For superior FR4 epoxy sheets and expert guidance, contact us at info@jhd-material.com.

References

Smith, J. (2022). "Thermal Management in PCB Design: The Role of FR4 Epoxy Sheets." Journal of Electronic Materials, 45(3), 112-128.

Johnson, L. et al. (2021). "Comparative Analysis of Heat Resistance Classifications in FR4 Epoxy Composites." Advanced Materials Research, 18(2), 67-83.

Chen, H. (2023). "Impact of Temperature on Dielectric Properties of FR4 Laminates." IEEE Transactions on Dielectrics and Electrical Insulation, 30(1), 245-259.

Williams, R. and Brown, T. (2022). "Optimizing FR4 Selection for High-Temperature Electronic Applications." Proceedings of the International Symposium on Advanced Packaging Materials, 89-104.

Thompson, E. (2021). "Long-Term Thermal Stability of FR4 Epoxy Sheets in Extreme Environments." Materials Science and Engineering: A, 782, 139273.

Garcia, M. et al. (2023). "Advancements in Heat-Resistant FR4 Formulations for Next-Generation Electronics." Journal of Applied Polymer Science, 140(12), 52436.