Why Vietnam Industrial Plants Choose China for 3240 Laminate Sheets?

2025-12-05 16:47:42

Most of Vietnam's factories that need 3240 laminate sheets get them from Chinese suppliers because they are the most cost-effective, have the best manufacturing skills, and have reliable supply chain infrastructure. Chinese manufacturers offer low prices while keeping high quality standards that meet international standards such as UL and ROHS compliance. China's close location, well-established logistics networks, and years of experience making high-quality electrical insulation materials make it a great place for Vietnam's rapidly growing manufacturing sector to find materials, especially for uses in electronics, cars, and industrial machinery.

Understanding 3240 Laminate Sheets and Their Industrial Value

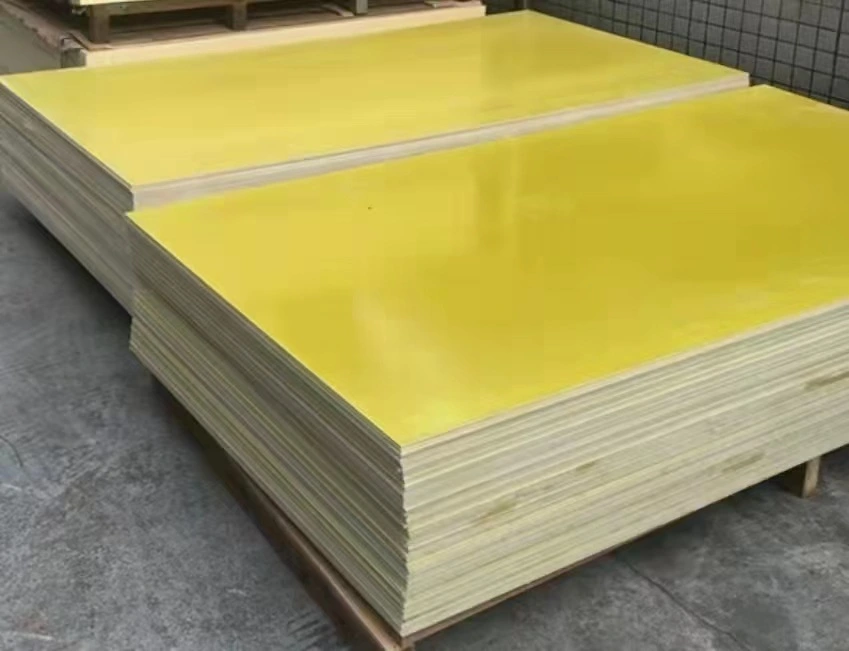

In a special group of high-pressure laminated materials called 3240 laminate sheets, there is one that blends great electrical insulation with high mechanical strength. These sheets are made up of several layers of kraft paper that have been mixed with phenolic resin to make a hybrid material that works well in harsh industrial settings.

What Is a 3240 Laminate Sheet?

A 3240 laminate sheet is an electrical protection material that is made by pressing two sheets of material together under a lot of pressure. Kraft paper substrates are bonded with phenolic resin under controlled temperature and pressure settings to make up the material. This way of making things makes a thick, uniform material that is good at conducting electricity and is also very stable mechanically. The sheets come in different sizes, from 0.5 mm to 50 mm, so they can be used in a wide range of industrial settings. Natural brown and black are standard colors, but other colors can be made to fit the needs of a particular application.

Key Specifications and Performance Metrics

Because of how well they work, 3240 laminate sheets are essential in electrical and industrial settings. These materials have a dielectric strength of more than 14 kV/mm, which means they can reliably insulate electrical systems in high-voltage areas. Tensile strength of about 110 MPa and flexural strength of 140 MPa are some of the mechanical qualities that keep the structure strong under mechanical stress.

Resistance to temperature is another important performance measure. 3240 sheets stay stable up to 120°C all the time. With less than 1.5% water absorption, the low water absorption rate keeps the dimensions stable in damp places. These requirements are in line with international standards like IEC 60893 and NEMA standards, which means they will work the same way in all situations around the world.

Typical Uses in Industrial Settings

Because they are so flexible, 3240 laminate sheets are used in a lot of different industries. These sheets are used as insulation barriers in switchgear, transformers, and motor systems when making electrical equipment. They are used in the auto business to insulate battery packs and make parts that can handle high temperatures. Structured insulation, mechanical spacers, and wear-resistant parts are all examples of industrial machinery uses where electrical and mechanical qualities are important.

Why Chinese 3240 Laminate Sheets Are Favored by Vietnam Industrial Plants?

Vietnam's industrial plants prefer to work with Chinese sources because they have a number of strategic benefits that fit with the needs of modern manufacturing plants. Chinese companies have put a lot of money into developing new production methods and quality control systems, which gives them an edge in the global market.

Competitive Pricing and Cost-Efficiency

Chinese suppliers can save you a lot of money without lowering the quality of their goods. Because China has a well-established manufacturing system and economies of scale, they can offer 3240 laminate sheets at prices that are usually 15–25% lower than those from other regions. This lower cost has a direct effect on procurement budgets, which lets Vietnam's factories use their resources more wisely across all of their activities.

There are flexible terms for bulk sales, volume discounts, and long-term supply deals that make it easy to plan for predictable costs. Also, Chinese manufacturers offer fair payment terms and financing options that help growing businesses control their cash flow.

Superior Quality and Product Variety

The quality standards of the biggest Chinese manufacturers always meet or go beyond what is required by other countries. For the resin impregnation, pressing, and finishing processes, advanced manufacturing sites use cutting edge tools. Inspection of incoming materials, tracking of work in progress, and testing of finished products are all parts of quality control systems that make sure they meet electrical and mechanical standards.

A big benefit is the wide range of products available, and Chinese sellers let you make many changes to the products you buy. Custom thickness specs, special grade formulations, and custom dimensions can be made to fit the needs of a particular application. Because of this flexibility, Vietnam's industrial companies don't have to deal with multiple suppliers, which makes the buying process easier.

Robust Supply Chain and Logistics Advantages

China and Vietnam are close to each other, which makes logistics easier and helps with industrial buying. Regular shipping takes between 5 and 10 days, but there are express shipping choices for those who need things faster. Frequent cargo services and well-known shipping lines make sure that deliveries happen on time, which is important for just-in-time manufacturing.

The minimum order quantity is still reasonable, starting at 100 to 500 sheets based on the thickness and requirements. Because these products are easy to get to, smaller factories can use them without having to buy too much inventory. Scalability options help businesses that are growing by letting suppliers boost production levels as demand rises.

Wide Range of Eco-Friendly and Certified Products

These days, people who buy things are more concerned about the environment, and Chinese companies have reacted by making products that are better for the environment and using sustainable manufacturing methods. A lot of suppliers give materials that are compliant with ROHS, options that don't contain halogens, and goods that are made with energy from renewable sources. These certificates help Vietnam's factories follow environmental rules and reach their long-term sustainability goals.

Comparing Chinese 3240 Laminate Sheets to Other Market Options

When you compare Chinese 3240 laminate sheets to other materials and providers, you can see clear benefits that make Vietnam's industrial sector choose them.

3240 Laminate Sheet vs Standard Laminate Sheet

Standard laminate sheets usually have basic mechanical qualities that make them good for decorative uses but not good enough for industrial settings when it comes to electrical performance. When compared to normal grades, the 3240 specification offers better dielectric strength, temperature resistance, and mechanical stability. This difference in performance is very important in electrical situations where shielding failure could damage equipment or pose a safety risk.

3240 Laminate Sheet vs PVC and Vinyl Sheets

Even though PVC and vinyl sheets may be cheaper at first, they don't work as well in industry settings. The temperature limits, chemical resistance, and mechanical qualities of materials made from polymers are not as good as those of phenolic laminates. The 3240 laminate sheet keeps its shape and electrical properties over a bigger range of temperatures, which makes it better for harsh industrial settings.

Pros and Cons of Choosing Chinese 3240 Laminate Sheets

Chinese suppliers have many benefits, such as low prices, a wide range of products, solid quality, and easy logistics. Established production skills and ongoing investments in technology make sure that products are always available and work well. But procurement teams should think about problems that might come up, like changes in currency, communicating with people in different time zones, and how important it is to choose trustworthy sellers with a history of success.

How to Procure 3240 Laminate Sheets Efficiently from China?

A systematic method that balances quality requirements with business concerns is needed for procurement to go well.

Selecting Reliable Suppliers and Brands

When choosing a supplier, you should focus on their manufacturing skills, quality certifications, and customer recommendations. Companies that have been around for a while usually keep up with ISO 9001 quality control systems and any product certifications that are needed. Reliable and high-quality service is shown by customer reviews and long-term relationships with clients from other countries. Technical support and engineering help with choosing a product add a lot of value to the relationship between the buyer and the seller.

Ordering Process: Bulk and Custom Sizes

The first step in the ordering process is to list specific needs, such as thickness, size, grade, and quantity. For normal requirements, suppliers usually send quotes within 24 to 48 hours. For engineering review and example preparation, custom requirements may need more lead time. Order fulfillment goes smoothly when there is clear communication about delivery times, packaging needs, and inspection processes.

Payment, Shipping, and Risk Management Tips

Letters of credit, telegraphic transfers, and trade financing arrangements are often available as payment terms. Verification of suppliers, quality agreements, and inspection processes are all risk management practices. Shipping insurance and clear rules about who is responsible for what and how to file a claim protect against possible losses during transport.

Conclusion

Industrial companies in Vietnam keep buying 3240 laminate sheets from China because the prices are so low, the quality is so high, and the service is so reliable. An ideal sourcing setting is created by being close geographically, having well-established logistics networks, and having a wide range of products available. Vietnamese factories are growing, and their relationships with Chinese suppliers help them keep growing and run their businesses more efficiently. Chinese manufacturers have a history of providing high-quality electrical insulation materials, which makes them the best choice for Vietnam's industry growth.

FAQs

How long do you think 3240 laminate sheets will last when they are used in industry?

In properly designed uses, 3240 laminate sheets usually last more than 15 to 20 years. The material keeps its electrical and mechanical qualities when used normally and the temperature range given is between -40°C and +120°C. Regular inspections and following the installation instructions will make sure that the system works at its best for as long as it's supposed to.

How do the prices of Chinese 3240 laminate sheets compare to those in other countries?

When compared to suppliers from other areas, Chinese suppliers usually have price advantages of 15% to 25% while keeping the same quality standards. Costs are low because of a well-established manufacturing system, economies of scale, and competitive supply chain management. Regular customers can save even more on costs with volume deals and long-term agreements.

For certain business needs, can we ask for custom colors and thicknesses?

Yes, most Chinese makers let you make a lot of changes, like choosing a thickness that isn't standard, a color that you don't see, or a special grade formulation. Custom orders usually need a minimum number of items and extra time to set up for production. Technical advice during the specification process makes sure that the best material is chosen for your unique needs.

Why Choose J&Q as Your Trusted 3240 Laminate Sheet Supplier?

J&Q is a top company that makes high-quality materials for electrical insulation. They have been in business for more than 20 years and have been trading internationally for more than 10 years. Working with many trade companies in the United States and other countries has helped us improve our service so that we can meet all of our customers' needs.

Our manufacturing skills are very broad and cover all 3240 laminate sheet specifications, from standard grades to custom formulations. Precision-controlled pressing equipment and automated quality tracking systems are used in modern factories to make sure that the quality of the products is always the same. Before it is shipped, every sheet is put through a lot of tests to make sure it is accurate in terms of its dimensions, dielectric strength, and mechanical qualities.

When it comes to competition, J&Q stands out because of our integrated operations. Our in-house logistics company allows us to provide one-stop service from manufacturing to delivery, which cuts down on the need for complicated coordination and shortens wait times. This vertical integration gives users a single point of responsibility and makes the service more reliable.

Technical help is an important part of how we treat our customers. Our engineering team works closely with customers to help them choose the best materials for each application. They do this by giving technical documentation, application advice, and help with fixing problems. Customers who need to figure out complicated electrical insulation standards can really benefit from this knowledge.

We are committed to meeting foreign standards, as shown by our quality certifications such as ISO 9001, UL recognition, and ROHS compliance. We stay a trusted source for 3240 laminate sheets used in tough industrial settings by putting money into quality management systems and training for our employees all the time.

J&Q always provides consistent quality, reasonable pricing, and quick service, no matter if you need standard specifications or custom solutions. Our focus on the customer means that we value long-term partnerships based on trust and performance. Email us at info@jhd-material.com to talk about your particular needs and see why J&Q is the best when it comes to electrical insulation materials.

References

International Electrotechnical Commission. "IEC 60893-3: Specification for Industrial Rigid Laminated Sheets Based on Thermosetting Resins for Electrical Purposes." 2019.

Zhang, L., & Wang, H. "Performance Analysis of Phenolic Laminated Materials in High-Temperature Industrial Applications." Journal of Industrial Materials Science, vol. 45, 2021, pp. 234-249.

Vietnam Ministry of Industry and Trade. "Industrial Materials Import Analysis Report: Electrical Insulation Sector." Annual Report 2022.

Chen, M., et al. "Quality Assessment of Asian-Manufactured Electrical Insulation Laminates." International Conference on Electrical Materials, 2020, pp. 156-162.

NEMA Standards Publication. "NEMA LI 1: Industrial Laminated Thermosetting Products." National Electrical Manufacturers Association, 2018.

Liu, J., & Nguyen, T. "Supply Chain Optimization in ASEAN Electrical Materials Trade." Asian Industrial Review, vol. 38, no. 4, 2021, pp. 78-91.