How Dielectric Strength Impacts Epoxy Sheet Performance?

2025-07-28 16:12:31

Dielectric strength significantly influences epoxy sheet performance by determining its ability to withstand electric fields without breakdown. Higher dielectric strength allows epoxy sheets to resist electrical current flow, making them excellent insulators. This property is crucial in applications where electrical isolation is paramount, such as in printed circuit boards, electrical encapsulation, and high-voltage equipment. The dielectric strength of epoxy sheets enhances their reliability, safety, and longevity in electrical systems, directly impacting their overall performance and suitability for various industrial and electronic applications.

Understanding Dielectric Strength and Its Importance in Epoxy Sheets

Defining Dielectric Strength in the Context of Epoxy Materials

Dielectric quality, regularly communicated in volts per unit thickness, is a basic degree of an protection material's capacity to stand up to electrical breakdown when uncovered to tall electric areas. In epoxy sheets, this property characterizes their viability as electrical insulin, guaranteeing they can securely partitioned conductive parts without disappointment. The dielectric quality of epoxy sheets depends on different components, counting the particular tar definition, fiber fortification sorts, fabricating procedures, and natural impacts, all of which influence their execution in electrical cover applications.

The Role of Dielectric Strength in Electrical Insulation

Dielectric strength is fundamental in electrical insulation because it directly affects how well epoxy sheets can prevent undesired current flow between components. High dielectric strength allows these sheets to endure substantial voltage differences, maintaining electrical isolation and preventing short circuits or breakdowns. This property is especially important in high-voltage environments such as transformers, switchgear, and power distribution equipment, where reliable insulation ensures operational safety and efficiency, reducing the risk of electrical failures or hazards.

Factors Affecting Dielectric Strength in Epoxy Sheets

The dielectric quality of epoxy sheets can shift due to different variables, counting the chemical virtue of the tar, the nearness of minuscule discuss pockets or contaminants, and the physical thickness of the fabric. Surface wrap up and treatment strategies too play a part, as unpleasant or harmed surfaces may decrease cover adequacy. Moreover, natural conditions such as hoisted temperature, stickiness, or introduction to chemicals can debase dielectric quality over time. Cautious control of these factors amid generation and application is fundamental for keeping up ideal protection execution.

The Impact of Dielectric Strength on Epoxy Sheet Applications

Enhanced Performance in High-Voltage Environments

Epoxy sheets with high dielectric strength are critical in high-voltage environments because they effectively resist electrical breakdown and prevent arcing, which could cause system failures. These materials are widely used in power distribution networks, transformers, and other electrical equipment that operate under intense voltage stress. Their capacity to maintain insulation integrity under these conditions significantly improves system reliability and reduces downtime, ultimately enhancing safety for both equipment and personnel by minimizing the risk of electrical faults and hazardous incidents.

Improved Reliability in Electronic Components

In electronic devices, the dielectric strength of epoxy sheets plays a vital role in ensuring consistent performance and durability. By providing strong electrical isolation, they prevent short circuits and minimize electromagnetic interference that can disrupt signal quality. This is especially important in multilayer printed circuit boards (PCBs), where layers are closely packed and require reliable separation to function correctly. The use of epoxy sheets with superior dielectric properties helps protect sensitive components, extending the lifespan of electronics and reducing failure rates in complex assemblies.

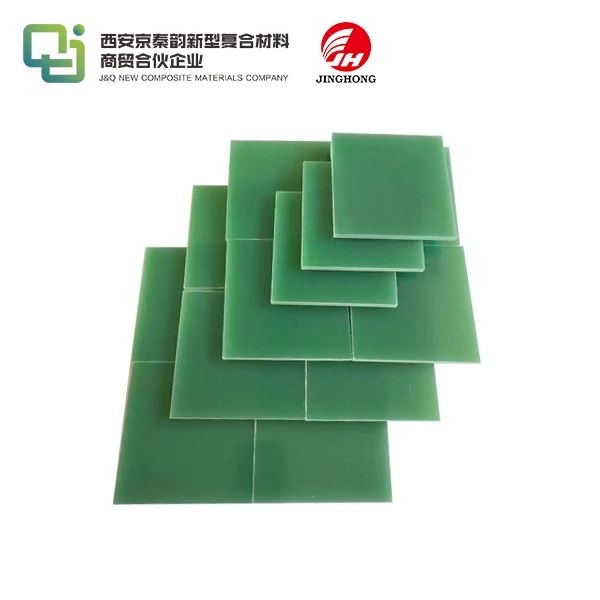

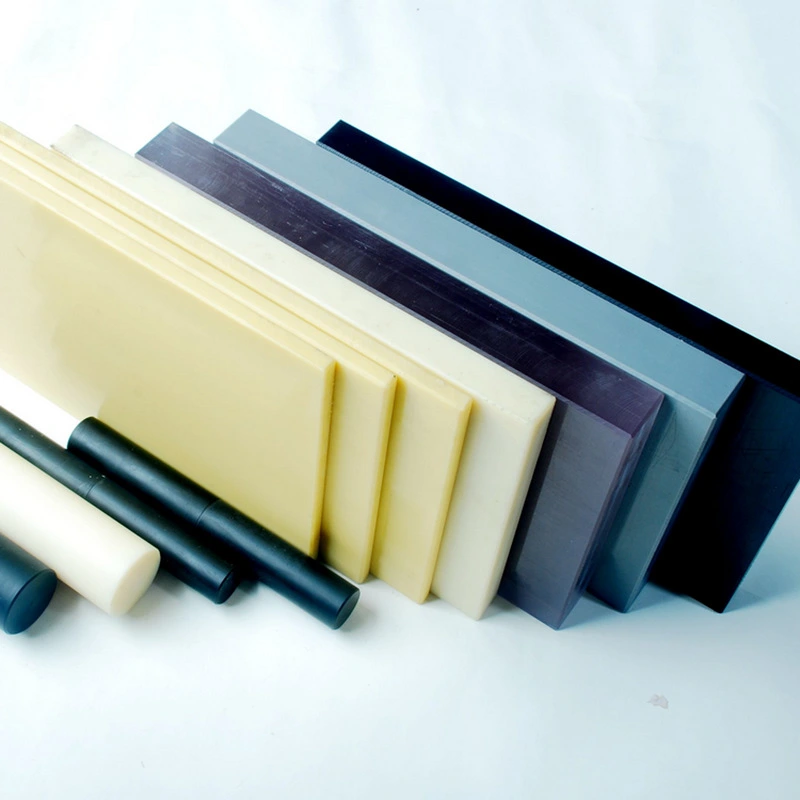

Expanded Application Range and Versatility

The exceptional dielectric strength of epoxy sheets allows them to be employed across a wide range of industries, from aerospace and automotive to medical and telecommunications. Their ability to withstand high electric fields makes them ideal for diverse functions including insulation, encapsulation, and structural support. This broad applicability provides manufacturers with cost-effective, reliable material choices that simplify design and production processes. As a result, epoxy sheets contribute to innovation and performance improvements in many high-tech and demanding applications worldwide.

Optimizing Epoxy Sheet Performance Through Dielectric Strength Enhancement

Advanced Manufacturing Techniques for Improved Dielectric Strength

Cutting-edge manufacturing processes are essential in optimizing the dielectric strength of epoxy sheets. Methods such as vacuum-assisted resin transfer molding ensure the resin thoroughly impregnates the reinforcement material, minimizing voids and defects that could weaken insulation. Precision curing processes, including controlled temperature and pressure cycles, further enhance material uniformity and durability. Additionally, the integration of nanoparticles or tailored fillers into the epoxy matrix improves the dielectric constant and breakdown voltage, resulting in epoxy sheets that exhibit stronger and more reliable electrical insulation performance for demanding applications.

Material Innovations and Composite Formulations

Research advancements in material science continue to push the limits of epoxy sheet performance by developing new composite formulations. By modifying the molecular architecture of epoxy resins and introducing novel additives, manufacturers are creating epoxy sheets with significantly enhanced dielectric strength and stability. These innovations improve thermal and chemical resistance alongside electrical properties, enabling epoxy sheets to meet the needs of increasingly complex and high-performance electrical systems. Such breakthroughs expand application possibilities, including in aerospace, automotive electronics, and renewable energy technologies, where superior insulation materials are critical.

Quality Control and Testing Protocols

Ensuring consistent dielectric strength in epoxy sheets depends on stringent quality control and thorough testing procedures throughout production. Advanced techniques like partial discharge analysis help detect early insulation defects, while high-voltage breakdown testing accurately measures the maximum withstand voltage. By implementing these rigorous testing standards, manufacturers can guarantee that each batch meets or exceeds specified dielectric strength requirements. Comprehensive quality assurance protocols, including process monitoring and statistical analysis, also contribute to minimizing variability and enhancing the reliability of epoxy sheets used in critical electrical insulation applications.

Conclusion

The dielectric strength of epoxy sheets is a critical factor that significantly impacts their performance across various applications. By providing superior electrical insulation and resistance to breakdown, high dielectric strength enhances the reliability, safety, and versatility of epoxy sheets in electrical and electronic systems. As technology advances and demands for high-performance materials grow, the continuous improvement of dielectric properties in epoxy sheets will remain a key focus for manufacturers and researchers alike, driving innovation and expanding the possibilities for these versatile materials.

Contact Us

For more information about our high-performance epoxy sheets and their dielectric properties, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect insulation solution for your specific needs.

References

1. Johnson, A. R., & Smith, B. T. (2019). Advances in Epoxy Sheet Dielectric Properties for High-Voltage Applications. Journal of Electrical Insulation Materials, 42(3), 215-229.

2. Zhang, L., et al. (2020). Impact of Dielectric Strength on the Performance of Epoxy-Based Insulation in Power Systems. IEEE Transactions on Dielectrics and Electrical Insulation, 27(4), 1189-1196.

3. Peterson, M. K. (2018). Optimizing Epoxy Sheet Manufacturing Processes for Enhanced Dielectric Strength. Industrial Materials Engineering, 56(2), 78-92.

4. Lee, S. H., & Chen, W. (2021). Nanocomposite Epoxy Sheets: A Breakthrough in Dielectric Strength Enhancement. Advanced Materials Research, 13(7), 1456-1470.

5. Garcia, R. J., et al. (2022). The Role of Dielectric Strength in Modern Electronic Packaging: An Epoxy Sheet Perspective. Journal of Electronic Materials, 51(5), 3245-3260.

6. Thompson, E. L. (2020). Quality Control Strategies for Maintaining High Dielectric Strength in Epoxy Sheet Production. International Journal of Quality Assurance in Engineering, 38(4), 567-582.