How FR4 Became the Industry Standard in PCB Boards?

2025-08-21 15:59:55

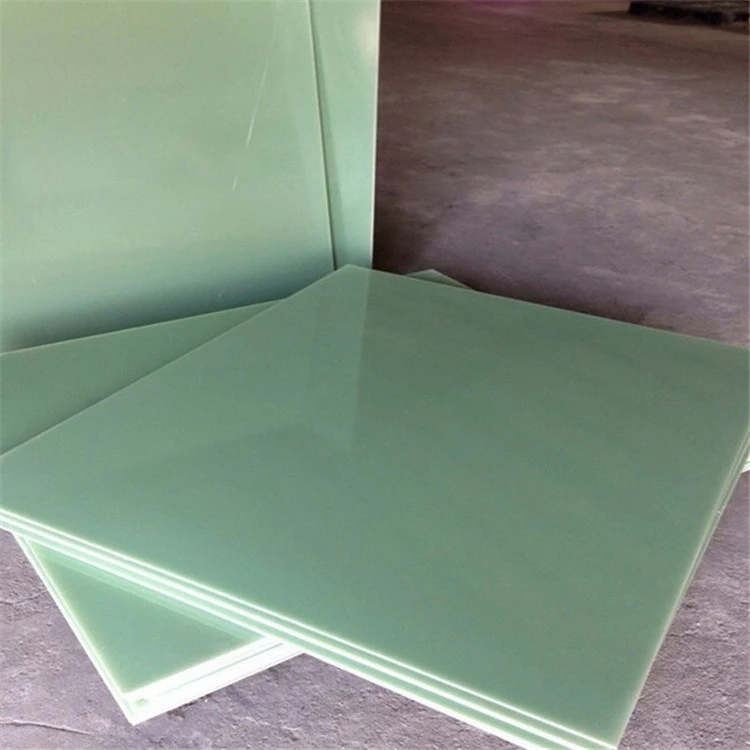

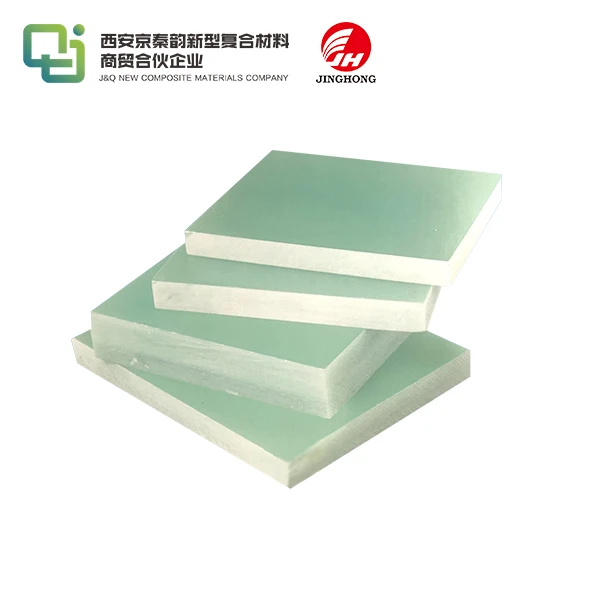

FR4 sheet became the industry standard in PCB boards due to its unique combination of properties that perfectly suit the needs of electronic manufacturing. Its excellent electrical insulation, mechanical strength, and flame-retardant qualities made it ideal for circuit board applications. The material's consistent performance, reliability, and cost-effectiveness led to widespread adoption across the electronics industry. As manufacturing processes evolved and demand for more complex electronic devices grew, FR4's versatility allowed it to adapt to changing requirements. This adaptability, coupled with its established track record, solidified FR4's position as the go-to material for PCB fabrication, making it the industry standard we know today.

What Properties Make FR4 Ideal for Printed Circuit Boards?

Electrical Insulation and Dielectric Strength

FR4 sheet exhibits exceptional electrical insulation properties, making it an ideal substrate for printed circuit boards. Its high dielectric strength allows it to effectively separate conductive layers and prevent short circuits. The material's low dielectric constant and loss tangent contribute to signal integrity, especially in high-frequency applications. These electrical characteristics ensure reliable performance across a wide range of electronic devices and operating conditions.

Mechanical Durability and Dimensional Stability

The mechanical properties of FR4 sheet contribute significantly to its suitability for PCBs. It offers excellent strength-to-weight ratio, allowing for robust yet lightweight board designs. FR4's dimensional stability under varying temperatures and humidity levels ensures that PCBs maintain their shape and size, crucial for maintaining precise component placement and connections. This durability also helps PCBs withstand the rigors of manufacturing processes, assembly, and long-term use in diverse environments.

Flame Retardancy and Thermal Management

As its name suggests, FR4's flame-retardant properties are a key feature. This characteristic is vital for ensuring the safety of electronic devices, especially in high-power applications or environments where fire hazards are a concern. Beyond fire resistance, FR4 also demonstrates good thermal management capabilities. It can withstand the heat generated during PCB operation and manufacturing processes like soldering, without significant degradation or warping. This thermal stability contributes to the overall reliability and longevity of PCBs made with FR4.

Evolution from Early PCB Materials to FR4 Dominance

Limitations of Early PCB Materials

Before FR4's rise to prominence, early PCB materials faced numerous challenges. Phenolic resins, used in the first generation of PCBs, were prone to moisture absorption and had limited heat resistance. These limitations often led to warping, delamination, and compromised electrical performance. Subsequent materials like epoxy-paper laminates offered improvements but still fell short in terms of durability and electrical properties. The electronics industry desperately needed a material that could meet the increasing demands of more complex and compact electronic devices.

Introduction and Initial Adoption of FR4

FR4 sheet was introduced as an evolution of its predecessor, G10 laminate. While G10 offered good electrical and mechanical properties, FR4's enhanced flame resistance gave it a significant advantage. The material quickly gained traction in military and aerospace applications, where safety and reliability were paramount. As manufacturing processes for FR4 improved and costs decreased, its adoption spread to commercial electronics. The material's versatility allowed it to be used in both single-layer and multi-layer PCB designs, further expanding its applicability across various electronic products.

Technological Advancements and FR4 Refinement

As the electronics industry evolved, so did FR4. Manufacturers continually refined the material composition and production processes to enhance its properties. These advancements led to FR4 variants with improved high-frequency performance, better thermal management, and increased reliability. The material's adaptability to new manufacturing techniques, such as laser drilling for high-density interconnects, ensured its continued relevance. FR4's ability to keep pace with technological progress solidified its position as the preferred PCB material across diverse applications, from consumer electronics to industrial equipment.

Standardization, Cost Efficiency, and Global Adoption

Industry Standards and Specifications

The widespread adoption of FR4 led to the development of industry standards and specifications. Organizations like IPC (Institute for Printed Circuits) established guidelines for FR4 properties and performance, ensuring consistency across manufacturers. These standards facilitated quality control and interoperability, critical factors in the globalized electronics supply chain. The standardization of FR4 also simplified the design and manufacturing processes for OEMs and PCB fabricators, contributing to its ubiquity in the industry.

Economic Factors Driving FR4 Adoption

FR4's cost-effectiveness played a crucial role in its dominance of the PCB market. As production volumes increased and manufacturing processes became more efficient, the price of FR4 sheet decreased significantly. This made it an attractive option for both high-volume consumer electronics and specialized industrial applications. The material's long shelf life and stability during storage further contributed to its economic appeal. Additionally, the widespread availability of FR4 from multiple suppliers ensured a stable supply chain, reducing risks and costs for manufacturers relying on the material.

Global Manufacturing Ecosystem

The global adoption of FR4 fostered the development of a vast manufacturing ecosystem. PCB fabricators worldwide invested in equipment and expertise optimized for FR4 processing. This global infrastructure enabled efficient production and quick turnaround times for PCB orders. The ubiquity of FR4 also facilitated knowledge sharing and innovation within the industry. As FR4 became the de facto standard, it created a common language for PCB design and manufacturing across different regions and market segments, further entrenching its position as the industry standard.

Conclusion

FR4's journey to becoming the industry standard in PCB boards is a testament to its exceptional properties and adaptability. Its combination of electrical insulation, mechanical strength, and flame retardancy made it the ideal material for evolving electronic applications. As the electronics industry grew and diversified, FR4's versatility allowed it to meet new challenges and requirements. The establishment of industry standards, coupled with cost efficiencies and a global manufacturing ecosystem, solidified FR4's position as the go-to material for PCB fabrication. While new materials continue to emerge for specialized applications, FR4 remains the backbone of the PCB industry, powering countless electronic devices worldwide.

Contact Us

Are you looking for high-quality FR4 sheets for your PCB manufacturing needs? Contact us today at info@jhd-material.com to learn more about our premium FR4 products and how we can support your electronic manufacturing projects.

References

1. Coombs, C. F. (2008). Printed circuits handbook. McGraw-Hill Professional.

2. Jawitz, M. W. (1997). Printed circuit board materials handbook. McGraw-Hill.

3. IPC-4101D: Specification for Base Materials for Rigid and Multilayer Printed Boards. (2018). IPC - Association Connecting Electronics Industries.

4. Tummala, R. R., Rymaszewski, E. J., & Klopfenstein, A. G. (1997). Microelectronics packaging handbook. Springer Science & Business Media.

5. Harper, C. A. (2004). Electronic materials and processes handbook. McGraw-Hill.

6. Gilleo, K. (2018). Printed circuit board materials: Past, present, and future. Circuits Assembly Magazine.