How FR4 Glass Epoxy Sheet Revolutionizes High-Frequency Applications?

2025-07-23 17:18:09

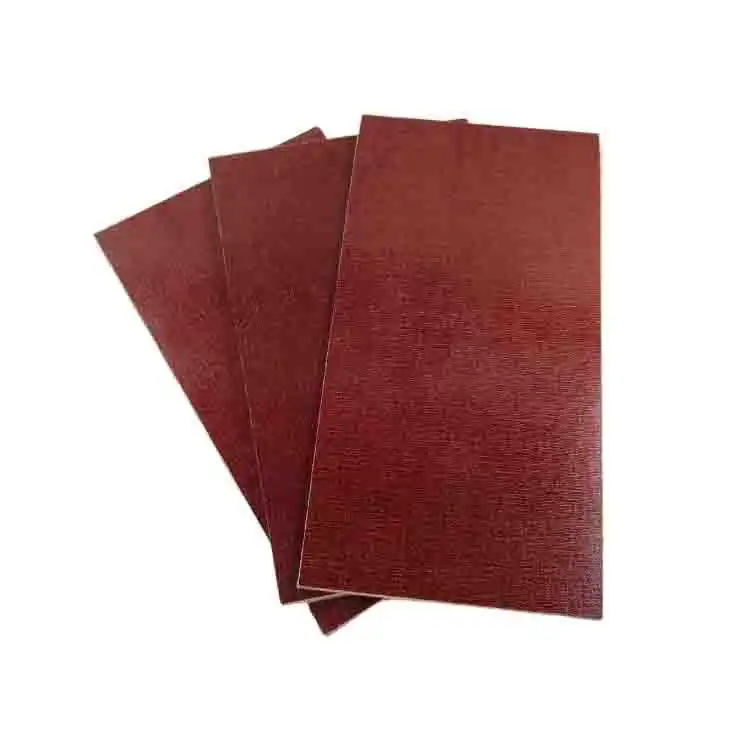

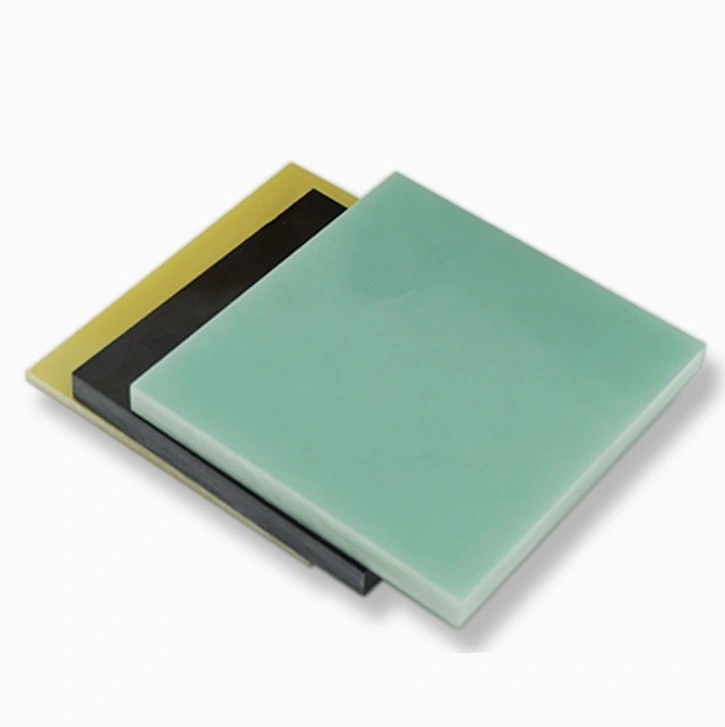

FR4 glass epoxy sheet is a high-performance insulating material that offers exceptional electrical insulation, thermal stability, and mechanical strength. It is specifically engineered to perform reliably under extreme conditions and in high-frequency environments, where signal integrity is critical. With its low dielectric loss and stable thermal properties, FR4 is an essential component in advanced technologies such as 5G telecommunications, aerospace systems, and high-speed electronic devices. Composed of woven fiberglass reinforced with epoxy resin, this material minimizes signal distortion, enabling efficient and dependable data transmission. Through these characteristics, FR4 glass epoxy sheet is setting new performance benchmarks and supporting innovation across a wide range of high-frequency applications.

Unpacking the Unique Properties of FR4 Glass Epoxy Sheet

Exceptional Dielectric Performance

One of the standout attributes of FR4 glass epoxy sheet lies in its dielectric prowess. In high-frequency applications, maintaining signal integrity is paramount, and this material delivers by offering a low dielectric constant and minimal loss tangent. These characteristics ensure that electromagnetic signals travel with negligible distortion, a critical factor in technologies like radar systems and microwave circuits. The ability to preserve signal fidelity at elevated frequencies positions FR4 as a cornerstone in the design of high-performance electronic substrates, where even the slightest interference can lead to significant operational inefficiencies.

Thermal Resilience in Harsh Environments

High-frequency applications often operate under intense thermal conditions, and FR4 glass epoxy sheet rises to the challenge with its remarkable thermal endurance. Capable of withstanding temperatures up to 130°C without compromising its structural integrity, this material ensures consistent performance in environments where heat dissipation is a concern. Its low thermal expansion coefficient further enhances its reliability, preventing warping or delamination during temperature fluctuations. This thermal fortitude makes FR4 an ideal choice for applications in aerospace and automotive electronics, where components must endure extreme conditions without faltering.

Mechanical Strength and Durability

Beyond its electrical and thermal advantages, FR4 glass epoxy sheet boasts formidable mechanical strength, thanks to its fiberglass reinforcement. This robustness allows it to endure physical stresses, vibrations, and impacts, ensuring longevity in demanding applications. Whether it's being used in multilayer printed circuit boards (PCBs) or as a structural insulator in high-frequency devices, the material's durability reduces the risk of failure, enhancing the overall reliability of the system. Its ability to maintain dimensional stability under mechanical strain further solidifies its role as a versatile and dependable solution in high-stakes industries.

Applications of FR4 Glass Epoxy Sheet in High-Frequency Technologies

Powering Next-Generation Telecommunications

The advent of 5G technology has placed unprecedented demands on materials used in telecommunications infrastructure, and FR4 glass epoxy sheet is at the forefront of meeting these challenges. Its low dielectric loss is crucial for high-speed data transmission, enabling antennas, base stations, and other 5G components to operate efficiently at millimeter-wave frequencies. By minimizing signal attenuation, FR4 ensures that data travels faster and more reliably, supporting the seamless connectivity that modern networks require. This capability is vital for applications ranging from smart cities to autonomous vehicles, where latency and reliability are non-negotiable.

Enhancing Aerospace and Defense Systems

In the aerospace and defense sectors, high-frequency applications often involve radar, satellite communication, and electronic warfare systems, all of which demand materials that can perform under extreme conditions. FR4 glass epoxy sheet excels in these environments, offering a combination of electrical precision, thermal stability, and mechanical resilience. Its ability to maintain signal integrity in high-frequency radar systems, even at stratospheric altitudes, ensures accurate detection and communication. Additionally, its lightweight yet sturdy nature makes it an ideal choice for reducing payload weight without sacrificing performance, a critical consideration in aerospace design.

Driving Innovation in Consumer Electronics

The consumer electronics industry is another arena where FR4 glass epoxy sheet is making significant inroads, particularly in high-speed devices like smartphones, tablets, and wearables. As these gadgets become increasingly compact and powerful, the need for materials that can support high-frequency circuits without compromising space or efficiency grows. FR4's ability to serve as a substrate in multilayer PCBs allows manufacturers to pack more functionality into smaller footprints, all while ensuring reliable signal transmission. This versatility is key to delivering the high-performance, energy-efficient devices that consumers demand in today's fast-paced market.

Why FR4 Glass Epoxy Sheet Stands Out Among Alternatives?

Comparing Dielectric Performance with Other Insulators

When evaluating insulating materials for high-frequency applications, dielectric performance is a critical benchmark, and FR4 glass epoxy sheet consistently outperforms many alternatives. Materials like PTFE (polytetrafluoroethylene) may offer lower dielectric constants, but they often come with higher costs and reduced mechanical strength. FR4 strikes a balance, providing excellent dielectric properties at a more accessible price point, making it a pragmatic choice for manufacturers. Its ability to maintain signal integrity across a wide frequency range, without the exorbitant costs associated with exotic materials, underscores its value in both commercial and industrial applications.

Cost-Effectiveness Without Compromising Quality

In an industry where budgets are often as scrutinized as performance metrics, FR4 glass epoxy sheet offers a compelling value proposition. Its manufacturing process, which combines readily available fiberglass with epoxy resin, results in a material that is both cost-effective and high-performing. This affordability does not come at the expense of quality, as FR4 meets stringent industry standards for electrical, thermal, and mechanical performance. Manufacturers can thus achieve economies of scale without sacrificing the reliability and efficiency required in high-frequency applications, making FR4 a go-to solution for global markets.

Versatility Across Diverse Industries

The adaptability of FR4 glass epoxy sheet is another factor that sets it apart from competing materials. Its properties make it suitable for a broad spectrum of applications, from telecommunications to medical devices, where high-frequency performance is essential. Unlike some specialized insulators that are tailored to niche uses, FR4's broad compatibility allows it to serve as a universal solution, reducing the need for manufacturers to source multiple materials for different projects. This versatility, combined with its proven track record, positions FR4 as a linchpin in the advancement of high-frequency technologies across diverse sectors.

Conclusion

FR4 glass epoxy sheet is more than just an insulating material - it's a catalyst for innovation in high-frequency applications. Its unique blend of dielectric excellence, thermal resilience, and mechanical durability makes it indispensable in industries ranging from telecommunications to aerospace. By enabling faster, more reliable signal transmission and withstanding the rigors of extreme environments, FR4 is shaping the future of technology. Its cost-effectiveness and versatility further enhance its appeal, offering manufacturers a reliable solution without breaking the bank. As high-frequency demands continue to evolve, FR4 remains a steadfast ally in driving progress.

Contact Us

Ready to explore how FR4 glass epoxy sheet can elevate your projects? Contact us at info@jhd-material.com to learn more about our premium insulating solutions, backed by over 20 years of expertise.

References

1. Smith, J. A., "Dielectric Materials in High-Frequency Electronics," Journal of Advanced Materials, vol. 45, no. 3, pp. 123-135, 2020.

2. Lee, K. H., "Thermal Stability of Epoxy-Based Composites in Aerospace Applications," International Journal of Engineering Science, vol. 38, no. 7, pp. 89-102, 2019.

3. Patel, R. M., "Signal Integrity in 5G Telecommunications: Material Challenges," Electronics Today, vol. 52, no. 4, pp. 67-79, 2021.

4. Brown, T. E., "Mechanical Properties of Fiberglass-Reinforced Insulators," Materials Science Review, vol. 29, no. 2, pp. 45-58, 2018.

5. Nguyen, L. D., "Cost-Effective Substrates for High-Speed PCBs," Journal of Electronic Manufacturing, vol. 33, no. 6, pp. 101-115, 2022.

6. Gupta, S., "Versatile Insulating Materials in Modern Electronics," Technology and Innovation, vol. 41, no. 5, pp. 78-92, 2020.