How FR4 Handles Thermal Expansion in PCB Designs?

2025-08-19 16:59:43

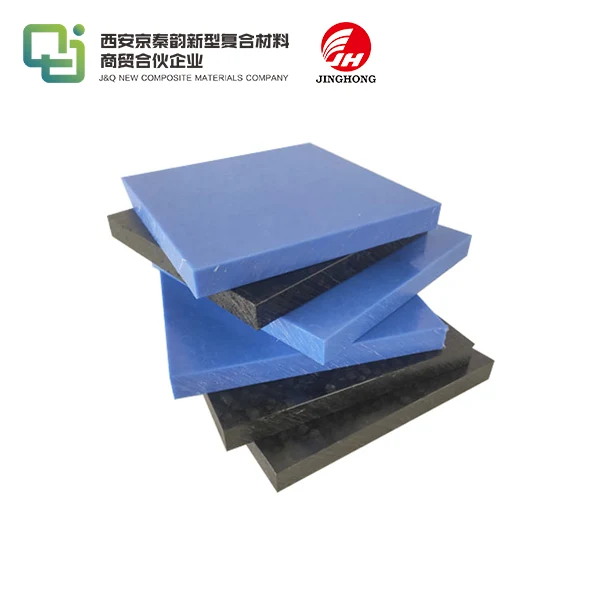

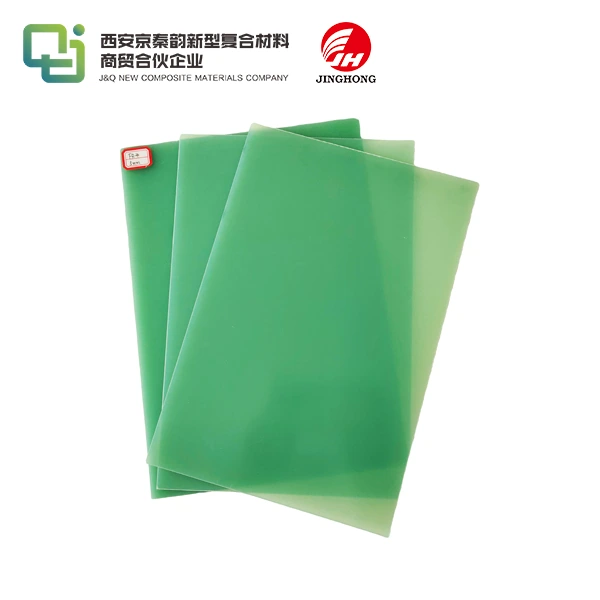

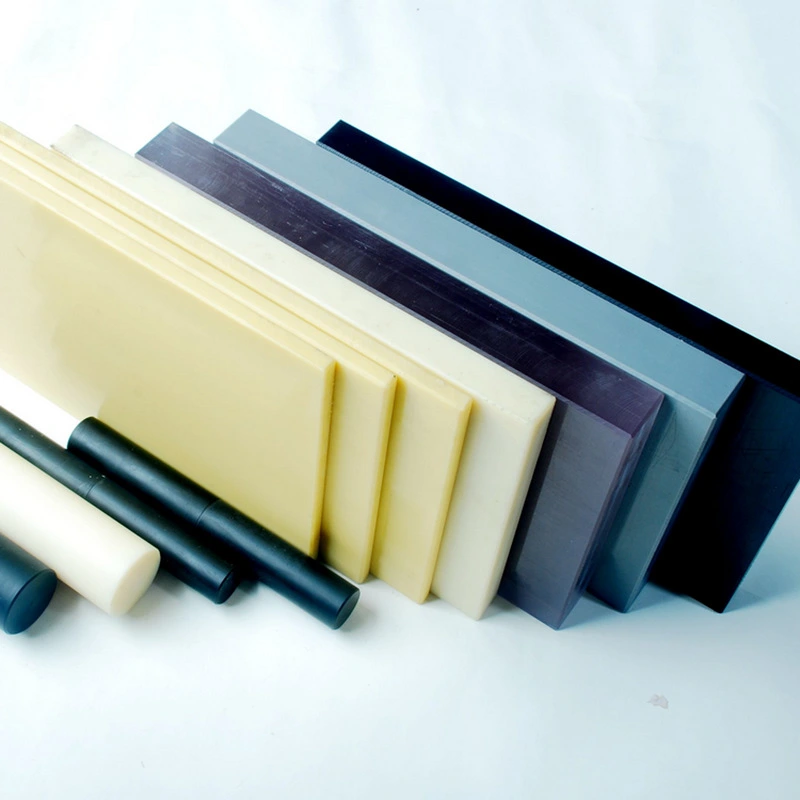

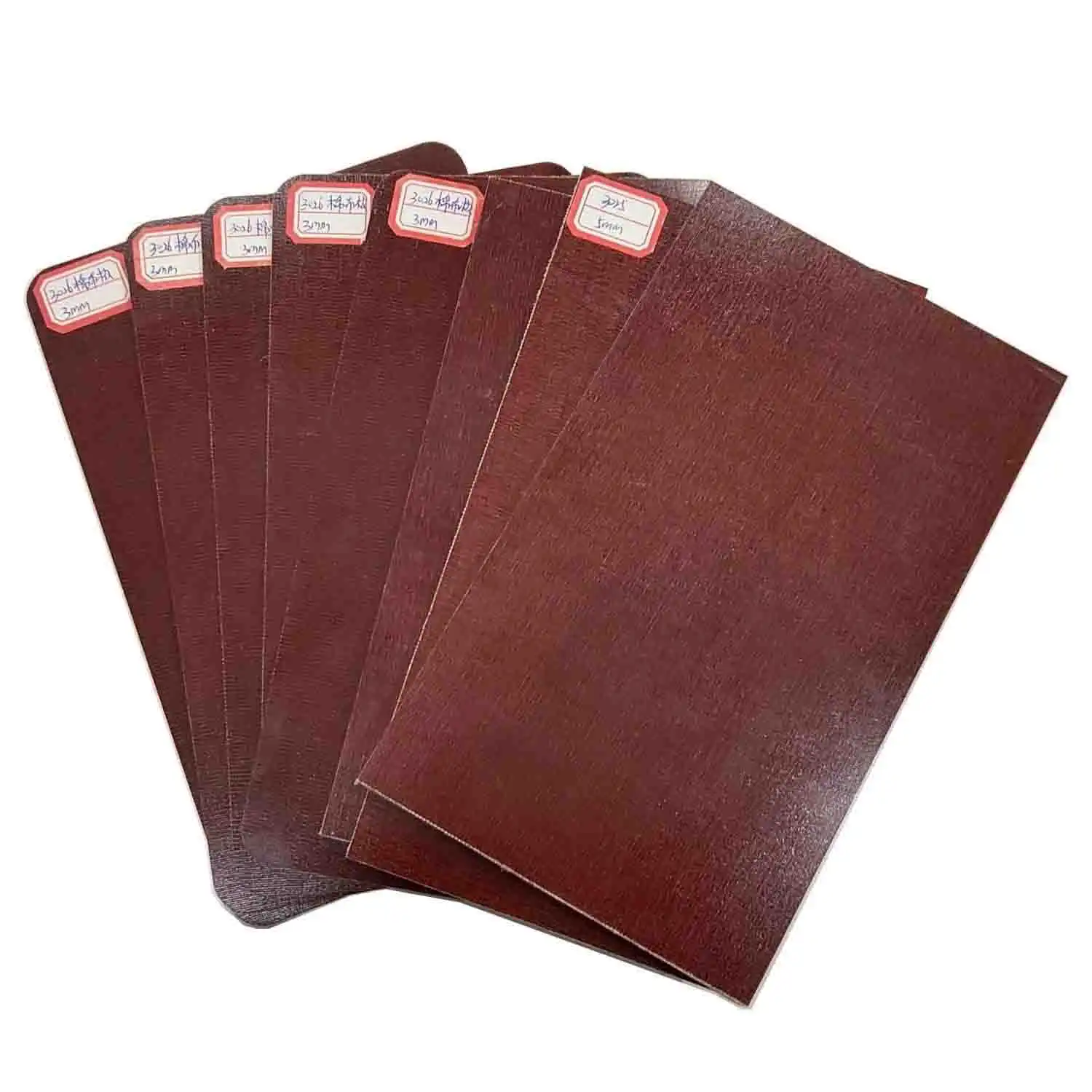

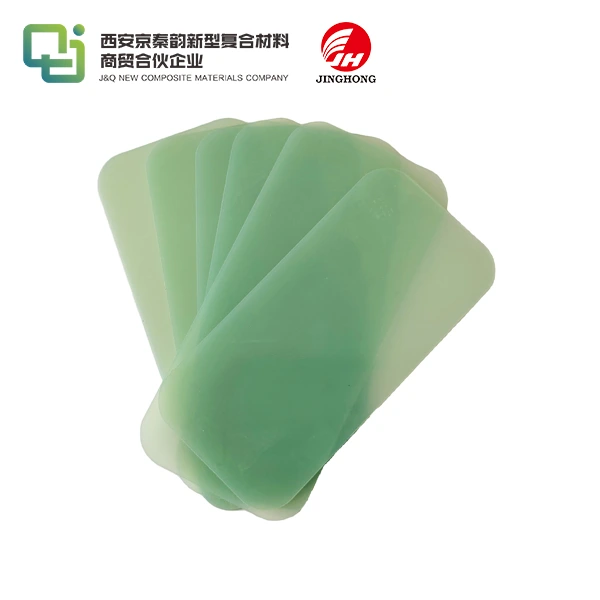

FR4 sheet, a widely used material in printed circuit board (PCB) manufacturing, exhibits remarkable properties in managing thermal expansion. This glass-reinforced epoxy laminate material effectively handles temperature fluctuations by maintaining dimensional stability. FR4's unique composition, combining woven fiberglass cloth with epoxy resin, allows it to resist warping and delamination under thermal stress. Its low coefficient of thermal expansion (CTE) minimizes the risk of solder joint failure and component detachment. By distributing heat evenly across the board, FR4 helps prevent localized hot spots that could compromise circuit integrity. This inherent ability to handle thermal expansion makes FR4 an ideal choice for PCB designs across various applications, from consumer electronics to industrial equipment.

What Is the Coefficient of Thermal Expansion (CTE) of FR4?

Understanding the Coefficient of Thermal Expansion (CTE) of FR4 is crucial for PCB designers aiming to create reliable and long-lasting electronic products. The CTE represents the rate at which a material expands or contracts with temperature changes. For FR4, this value plays a significant role in determining how well the material can withstand thermal stress without compromising the integrity of the PCB.

Numerical Values and Significance

FR4 sheet typically exhibits a CTE ranging from 50 to 70 ppm/°C in the x and y directions (in-plane), and approximately 200 to 250 ppm/°C in the z-direction (out-of-plane). These values indicate that FR4 expands more in the thickness direction than laterally when subjected to temperature changes. This anisotropic behavior is due to the layered structure of FR4, where glass fibers provide reinforcement in the x and y directions.

Comparison with Other Materials

When compared to other PCB materials, FR4's CTE values are relatively low. For instance, polyimide, another common PCB material, has a CTE of about 20 ppm/°C, while PTFE-based materials can have CTEs as high as 280 ppm/°C. The moderate CTE of FR4 makes it compatible with a wide range of components and suitable for various applications, striking a balance between thermal stability and cost-effectiveness.

Impact on PCB Design

The CTE of FR4 directly influences PCB design considerations. Designers must account for potential expansion and contraction when placing components, especially in applications involving extreme temperature fluctuations. Understanding FR4's CTE helps in predicting potential stress points and implementing design strategies to mitigate thermal-related issues, ensuring the longevity and reliability of the final product.

Managing Layer Delamination and Warping in Multilayer Boards

Multilayer PCBs, while offering increased functionality and component density, face unique challenges related to thermal expansion. Layer delamination and board warping are two primary concerns that PCB designers must address when working with FR4 sheet in multilayer configurations. Effective management of these issues is essential for producing reliable and long-lasting electronic devices.

Strategies to Prevent Delamination

Delamination occurs when the layers of a multilayer PCB separate due to thermal stress. To prevent this, designers employ several strategies:

- Balanced Layer Stack-up: Distributing copper layers evenly throughout the board helps equalize stress.

- Proper Prepreg Selection: Choosing prepreg materials with compatible CTEs reduces internal stress.

- Controlled Drilling Processes: Implementing precise drilling techniques minimizes damage to inner layers.

- Enhanced Adhesion: Utilizing specialized bonding materials improves layer-to-layer adhesion strength.

Techniques for Minimizing Warping

Board warping can lead to assembly difficulties and potential component failure. Designers combat warping through:

- Symmetrical Design: Creating a symmetrical layer stack-up balances internal stresses.

- Copper Distribution: Evenly distributing copper across layers and using copper thieving techniques.

- Thermal Management: Implementing proper thermal management strategies to distribute heat evenly.

- Material Selection: Choosing FR4 variants with lower CTEs for applications prone to warping.

Post-Processing Considerations

After fabrication, certain post-processing steps can further mitigate delamination and warping risks:

- Controlled Cooling: Gradually cooling boards after high-temperature processes reduces internal stress.

- Moisture Management: Proper storage and handling prevent moisture absorption that can lead to delamination.

- Stress Relief: Implementing stress relief patterns in copper planes can reduce overall board stress.

- Quality Inspection: Rigorous quality control measures help identify potential issues before assembly.

FR4 Compatibility with High-Density and High-Temp Assemblies

As electronic devices become more compact and powerful, the demand for high-density and high-temperature PCB assemblies increases. FR4's compatibility with these advanced designs is a critical factor in its continued popularity. Understanding how FR4 sheet performs under these conditions is essential for designers pushing the boundaries of PCB technology.

Performance in High-Density Applications

FR4's suitability for high-density designs stems from its excellent electrical and mechanical properties:

- Fine-Pitch Compatibility: FR4 supports fine-pitch component placement and routing.

- Layer Count Flexibility: It allows for high layer counts, enabling complex multilayer designs.

- Signal Integrity: FR4's stable dielectric properties maintain signal integrity in dense layouts.

- Thermal Management: Its thermal conductivity helps dissipate heat in tightly packed designs.

Adaptation to High-Temperature Environments

While standard FR4 has limitations in extreme temperature applications, modified versions can handle higher temperatures:

- High-Tg FR4: Variants with higher glass transition temperatures (Tg) offer improved thermal stability.

- Polyimide Blends: FR4-polyimide hybrids provide enhanced temperature resistance.

- Ceramic-Filled FR4: These materials offer improved thermal conductivity for better heat dissipation.

- Surface Treatments: Specialized coatings can enhance FR4's resistance to high-temperature environments.

Design Considerations for Extreme Conditions

When using FR4 in high-density or high-temperature applications, designers must consider:

- Thermal Expansion Management: Implementing design strategies to mitigate CTE mismatches.

- Component Selection: Choosing components compatible with FR4's thermal properties.

- Thermal Simulation: Utilizing thermal modeling to predict and address potential hot spots.

- Material Grade Selection: Selecting the appropriate FR4 grade based on specific application requirements.

Conclusion

FR4's ability to handle thermal expansion in PCB designs showcases its versatility and reliability in the electronics industry. Its moderate CTE, combined with strategies for managing layer delamination and warping, makes it suitable for a wide range of applications, including high-density and high-temperature assemblies. As PCB technology continues to advance, FR4 remains a cornerstone material, adaptable to evolving design challenges. By understanding and leveraging FR4's thermal properties, designers can create robust, long-lasting PCBs that meet the demands of modern electronic devices.

Contact Us

For more information about our FR4 sheets and how they can benefit your PCB designs, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in choosing the right FR4 solution for your specific needs.

References

1. Coombs, C. F. (2008). Printed Circuits Handbook. McGraw-Hill Education.

2. Jawitz, M. W., & Jawitz, M. J. (2007). Materials for Rigid and Flexible Printed Wiring Boards. CRC Press.

3. Mannan, S. H., & Clode, M. P. (2004). Predicting Solder Joint Reliability in Electronic Packaging. Journal of Electronic Materials, 33(11), 1323-1330.

4. Tummala, R. R. (2001). Fundamentals of Microsystems Packaging. McGraw-Hill Education.

5. Ghosh, A., & Mal, A. K. (2018). Thermal Expansion Behavior of FR4 Laminates in Electronic Packaging. Journal of Electronic Packaging, 140(2), 021001.

6. Minges, M. L. (1989). Electronic Materials Handbook: Packaging. ASM International.