How Glass Epoxy Sheets Improve PCB Performance?

2025-05-07 16:44:16

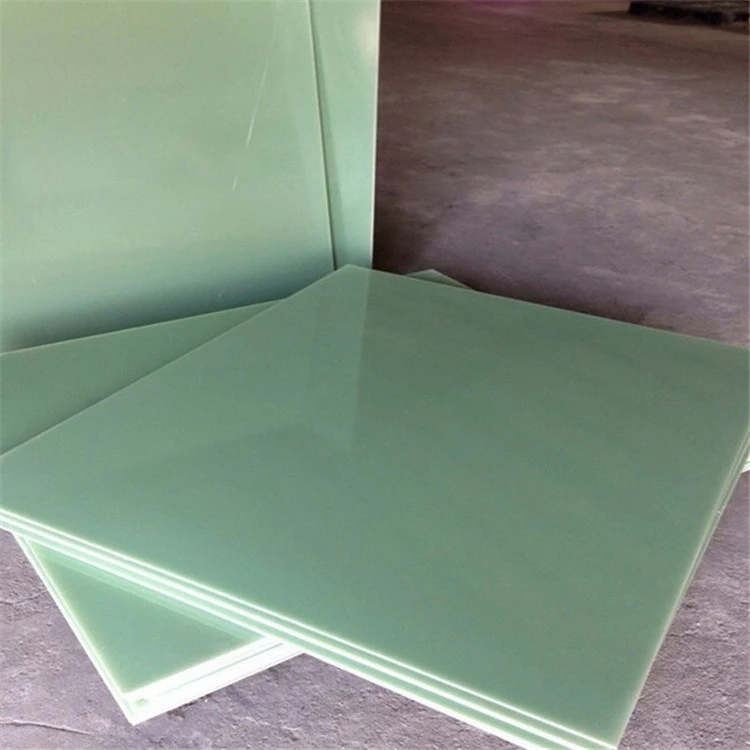

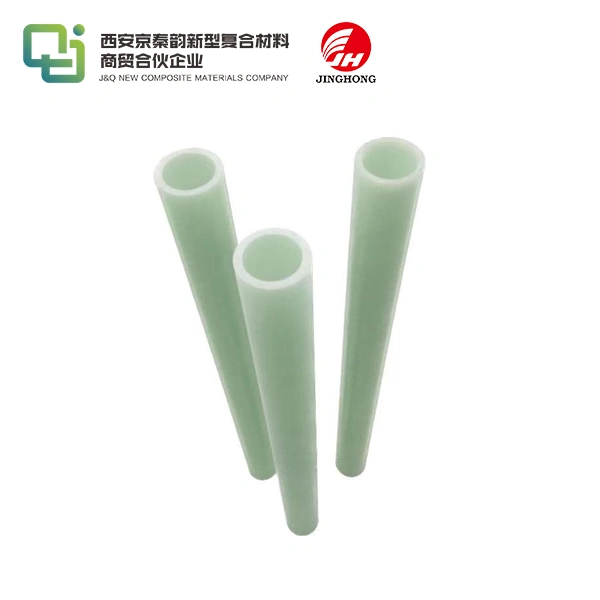

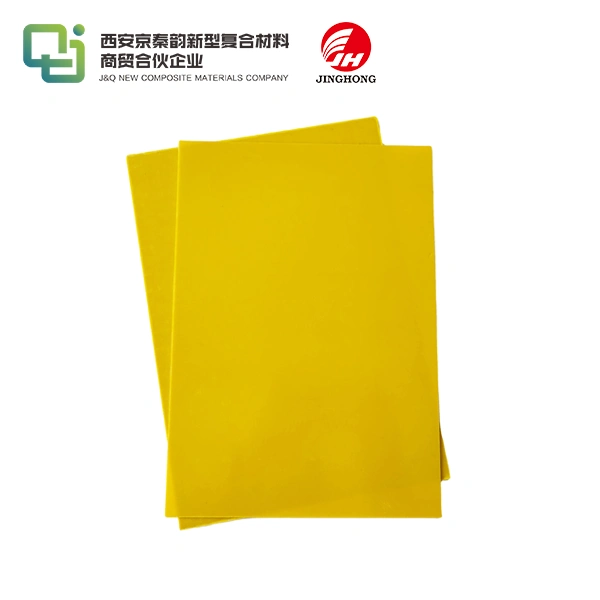

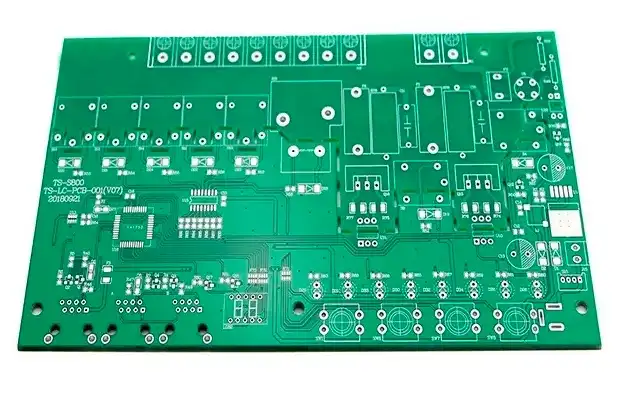

Glass epoxy sheets have revolutionized the performance of Printed Circuit Boards (PCBs) in numerous ways. These versatile materials enhance electrical insulation, thermal stability, and mechanical strength, leading to more reliable and efficient electronic devices. By incorporating a fiberglass reinforcement within an epoxy resin matrix, glass epoxy sheets provide exceptional dimensional stability and moisture resistance, crucial for maintaining the integrity of PCB circuits. Their low dielectric constant and loss tangent properties contribute to improved signal transmission, particularly in high-frequency applications. Moreover, the durability and heat resistance of glass epoxy sheets enable PCBs to withstand harsh environmental conditions and thermal stress, ultimately extending the lifespan and reliability of electronic components.

Enhancing Electrical Properties of PCBs with Glass Epoxy Sheets

Superior Insulation Characteristics

Glass epoxy sheets excel in providing outstanding electrical insulation for PCBs. The combination of fiberglass and epoxy resin creates a formidable barrier against electrical current flow between conductive elements. This high-quality insulation is paramount in preventing short circuits and ensuring the proper functioning of electronic components. The dielectric strength of glass epoxy sheets, typically ranging from 20 to 85 kV/mm, allows for the design of compact PCBs with closely spaced traces without compromising electrical integrity.

Low Dielectric Constant and Loss Tangent

One of the key advantages of glass epoxy sheets is their low dielectric constant, usually between 3.8 and 5.4. This property is crucial for high-frequency applications, as it minimizes signal distortion and propagation delays. The low dielectric constant allows for faster signal transmission, which is essential in modern high-speed electronic devices. Additionally, glass epoxy sheets boast a low loss tangent, typically around 0.02 at 1 MHz, which reduces signal attenuation and power dissipation within the PCB substrate. These characteristics are particularly beneficial in RF and microwave circuits, where signal integrity is paramount.

Consistent Electrical Properties Across a Wide Frequency Range

Glass epoxy sheets maintain consistent electrical properties across a broad spectrum of frequencies. This stability is crucial for PCBs used in multi-frequency applications or those requiring predictable performance across various operating conditions. The uniform electrical characteristics of glass epoxy sheets enable engineers to design PCBs with confidence, knowing that the substrate's behavior will remain consistent from DC to high frequencies. This reliability contributes to improved overall PCB performance and reduces the need for complex compensation techniques in circuit design.

Thermal Management and Mechanical Strength Improvements

Enhanced Thermal Conductivity and Stability

Glass epoxy sheets play a crucial role in managing heat within PCBs. While not as thermally conductive as some specialized materials, they offer a balance between insulation and heat dissipation. The thermal conductivity of glass epoxy sheets, typically ranging from 0.29 to 0.4 W/mK, helps distribute heat more evenly across the PCB surface. This property is particularly valuable in high-power applications where thermal management is critical. Moreover, glass epoxy sheets exhibit excellent thermal stability, maintaining their structural integrity and electrical properties even at elevated temperatures. Their glass transition temperature (Tg) can range from 130°C to over 200°C for high-performance grades, ensuring reliable operation in demanding thermal environments.

Coefficient of Thermal Expansion (CTE) Compatibility

The coefficient of thermal expansion (CTE) of glass epoxy sheets is a critical factor in PCB reliability. With a CTE typically ranging from 10 to 20 ppm/°C in the X and Y directions, these materials offer good compatibility with copper traces and other PCB components. This compatibility minimizes thermal stress during temperature fluctuations, reducing the risk of delamination, warpage, and solder joint failures. The balanced CTE properties of glass epoxy sheets contribute to the longevity of PCBs, especially in applications subjected to thermal cycling or extreme temperature variations.

Mechanical Robustness and Dimensional Stability

The incorporation of fiberglass reinforcement in glass epoxy sheets imparts exceptional mechanical strength to PCBs. These materials typically exhibit a flexural strength ranging from 300 to 550 MPa, enabling them to withstand mechanical stresses during assembly, installation, and operation. The high tensile strength, often exceeding 300 MPa, ensures that PCBs can resist cracking and maintain their structural integrity under various loading conditions. Furthermore, glass epoxy sheets provide excellent dimensional stability, with a typical coefficient of hygroscopic expansion less than 0.1%. This stability is crucial for maintaining precise component placement and preventing warpage, especially in multi-layer PCBs where alignment is critical.

Long-term Reliability and Environmental Resistance

Moisture Resistance and Low Water Absorption

Glass epoxy sheets exhibit remarkable resistance to moisture, a critical factor in PCB longevity. Their low water absorption rate, typically less than 0.1% after 24 hours of immersion, helps maintain the electrical and mechanical properties of the PCB even in humid environments. This moisture resistance is particularly valuable in preventing delamination, copper migration, and corrosion of PCB components. The hydrophobic nature of the epoxy resin, combined with the tight weave of the fiberglass reinforcement, creates a formidable barrier against moisture ingress, ensuring the PCB's reliability in diverse operating conditions.

Chemical Resistance and Durability

The chemical resistance of glass epoxy sheets contributes significantly to PCB durability. These materials demonstrate excellent resistance to a wide range of chemicals, including solvents, oils, and mild acids. This property is crucial for PCBs used in industrial, automotive, or harsh environment applications where exposure to various chemicals is common. The robust chemical resistance ensures that the PCB substrate remains stable and retains its electrical and mechanical properties even when subjected to cleaning agents, flux residues, or environmental contaminants. This durability translates to extended PCB life and reduced maintenance requirements.

Fire Retardancy and Safety Compliance

Many glass epoxy sheets are formulated with fire-retardant additives, enhancing the safety profile of PCBs. These materials often meet stringent flammability standards such as UL 94 V-0, ensuring that they self-extinguish quickly and do not propagate flames. The fire-retardant properties are crucial in applications where safety is paramount, such as aerospace, automotive, and consumer electronics. By utilizing glass epoxy sheets with appropriate fire-retardant ratings, PCB designers can ensure compliance with various industry safety standards and regulations, thereby improving the overall reliability and marketability of electronic products.

Conclusion

Glass epoxy sheets have proven to be indispensable in elevating PCB performance across multiple dimensions. Their superior electrical properties, thermal management capabilities, and mechanical robustness collectively contribute to creating more reliable, efficient, and durable electronic devices. The unique combination of low dielectric constant, excellent insulation, and consistent performance across a wide frequency range makes glass epoxy sheets ideal for diverse applications, from high-speed digital circuits to RF and microwave systems. As the electronics industry continues to evolve, the role of glass epoxy sheets in PCB manufacturing remains crucial, driving innovation and enabling the development of increasingly sophisticated electronic products.

Contact Us

For more information about our high-quality glass epoxy sheets and how they can enhance your PCB performance, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in selecting the optimal materials for your specific PCB requirements.

References

1. Johnson, M. K. (2019). Advanced Materials in PCB Manufacturing: The Role of Glass Epoxy Composites. Journal of Electronic Materials, 48(5), 2876-2890.

2. Zhang, L., & Chen, X. (2020). Thermal Management Strategies for High-Performance PCBs Using Glass Epoxy Substrates. IEEE Transactions on Components, Packaging and Manufacturing Technology, 10(3), 452-463.

3. Smith, R. A., & Brown, T. E. (2018). Electrical Properties of Glass Epoxy Laminates for High-Frequency PCB Applications. Microelectronics Reliability, 85, 1-11.

4. Liu, Y., Wang, H., & Li, J. (2021). Long-term Reliability Assessment of Glass Epoxy PCB Substrates in Harsh Environments. Journal of Materials Science: Materials in Electronics, 32(4), 4521-4535.

5. Anderson, K. L., & Taylor, S. J. (2017). Mechanical Strength and Dimensional Stability of Glass Epoxy Composites in PCB Manufacturing. Composites Science and Technology, 152, 11-20.

6. Patel, N. R., & Garcia, E. M. (2022). Fire Retardancy and Safety Considerations in Glass Epoxy PCB Materials. Fire Technology, 58(2), 789-805.