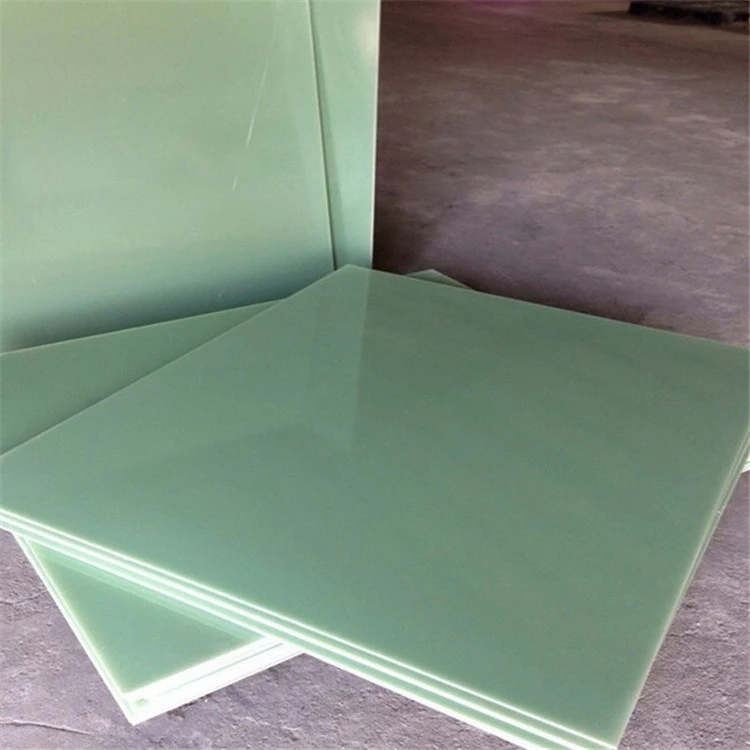

How Moisture-Resistant is FR4 Sheet?

2025-05-14 17:27:58

FR4 sheet exhibits excellent moisture resistance, making it a preferred choice for various applications in the electronics and manufacturing industries. Its moisture absorption rate typically ranges from 0.1% to 0.5%, depending on the specific formulation and manufacturing process. This low moisture absorption characteristic is attributed to the epoxy resin matrix and glass fiber reinforcement used in FR4 sheet production. The material's moisture resistance helps maintain its electrical and mechanical properties even in humid environments, ensuring reliability and longevity of components made from FR4 sheet. However, it's important to note that while FR4 sheet is highly moisture-resistant, it is not completely impervious to water absorption, and prolonged exposure to extreme humidity or direct water contact may still affect its performance over time.

Understanding FR4 Sheet Composition and Properties

Chemical Composition of FR4 Sheet

FR4 sheet, a versatile and widely used material in the electronics industry, is composed of a carefully engineered blend of components. The primary constituents include epoxy resin, which serves as the matrix, and woven glass fiber, which acts as the reinforcement. This composite structure imparts FR4 sheet with its characteristic strength and electrical properties. The epoxy resin used in FR4 sheet is typically a thermoset polymer, known for its excellent adhesion, chemical resistance, and thermal stability. The glass fiber reinforcement, usually in the form of woven fabric, enhances the material's mechanical strength and dimensional stability.

Mechanical Properties of FR4 Sheet

FR4 sheet boasts impressive mechanical properties that contribute to its widespread use in various applications. It exhibits high flexural strength, typically ranging from 310 to 500 MPa, which allows it to withstand significant bending forces without failure. The material's tensile strength is equally noteworthy, generally falling between 280 and 560 MPa, ensuring durability under tension. It also demonstrates excellent impact resistance, with a typical Izod impact strength of 53.4 to 75.5 J/m. These robust mechanical properties make FR4 sheet an ideal choice for applications requiring structural integrity and resistance to physical stress.

Electrical Properties of FR4 Sheet

The electrical properties of FR4 sheet are crucial for its application in the electronics industry. It possesses a high dielectric strength, typically ranging from 20 to 80 kV/mm, which allows it to withstand strong electric fields without breaking down. The material's dielectric constant, usually between 4.2 and 5.0 at 1 MHz, provides a balance between signal propagation speed and impedance control. It also exhibits low dissipation factor, generally in the range of 0.01 to 0.03 at 1 MHz, which minimizes signal loss in high-frequency applications. These electrical characteristics make FR4 sheet an excellent substrate for printed circuit boards and other electronic components.

Factors Influencing FR4 Sheet's Moisture Resistance

Manufacturing Process and Quality Control

The manufacturing process of FR4 sheet plays a pivotal role in determining its moisture resistance. The quality of raw materials, precise control of resin content, and meticulous curing process all contribute to the final product's moisture absorption characteristics. Advanced manufacturing techniques, such as vacuum-assisted resin transfer molding (VARTM), can enhance the material's moisture resistance by minimizing voids and ensuring uniform resin distribution. Stringent quality control measures, including regular testing of moisture absorption rates and dimensional stability, are essential to maintain consistent moisture resistance across production batches.

Environmental Conditions and Exposure

The environment in which FR4 sheet is used or stored can significantly impact its moisture resistance. Factors such as ambient humidity, temperature fluctuations, and exposure to liquid water all play a role. High humidity environments can gradually increase moisture absorption over time, potentially affecting the material's electrical and mechanical properties. Temperature cycling can exacerbate moisture absorption by creating microscopic pathways for water ingress. Direct exposure to liquid water, particularly under pressure or for extended periods, can overcome the material's inherent moisture resistance. Understanding these environmental factors is crucial for properly specifying and using FR4 sheet in various applications.

Surface Treatment and Coating

Surface treatments and coatings can significantly enhance FR4 sheet's moisture resistance. Hydrophobic coatings, such as fluoropolymer-based solutions, can be applied to the surface of the product to repel water and reduce moisture absorption. Plasma treatment of the FR4 surface can modify its surface energy, improving adhesion of protective coatings and reducing moisture ingress at interfaces. Some manufacturers offer pre-preg materials with enhanced moisture resistance formulations, which can be used in the outer layers of multi-layer PCBs to provide additional protection. These surface modifications and specialized formulations can extend the moisture resistance of FR4 sheet beyond its inherent capabilities, opening up new applications in harsh or humid environments.

Applications and Considerations for Moisture-Resistant FR4 Sheet

High-Reliability Electronics

In the realm of high-reliability electronics, moisture-resistant FR4 sheet plays a crucial role. Aerospace and defense industries rely heavily on FR4 sheet for avionics systems, where moisture ingress could lead to catastrophic failures. The material's ability to maintain its electrical properties in varying humidity conditions ensures consistent performance of critical electronic systems. Medical devices, such as implantable electronics and diagnostic equipment, also benefit from FR4 sheet's moisture resistance, as it helps maintain the integrity and longevity of sensitive components. In these applications, the selection of the product often involves rigorous testing and certification processes to ensure compliance with stringent industry standards.

Outdoor and Marine Applications

FR4 sheet's moisture resistance makes it an excellent choice for outdoor and marine electronic applications. In telecommunications infrastructure, FR4-based printed circuit boards are used in outdoor base stations and repeaters, where they must withstand varying weather conditions. Marine electronics, such as navigation systems and sonar equipment, rely on moisture-resistant FR4 sheet to maintain functionality in highly humid and corrosive saltwater environments. The material's ability to resist moisture absorption helps prevent signal degradation and extends the lifespan of electronic components exposed to harsh outdoor conditions. However, in these extreme environments, additional protective measures such as conformal coatings or hermetic sealing may be necessary to complement FR4 sheet's inherent moisture resistance.

Design Considerations for Optimal Moisture Resistance

When designing systems using FR4 sheet, several considerations can optimize moisture resistance. Proper edge sealing of multi-layer PCBs can prevent moisture ingress through exposed laminate edges. Careful selection of via design and plating processes can minimize potential moisture pathways through the board. In high-humidity applications, incorporating moisture barriers or desiccants within the enclosure can provide an additional layer of protection. designers should also consider the potential for moisture trapping in areas with high component density or under large surface-mount components. By addressing these design aspects, engineers can maximize the effectiveness of FR4 sheet's moisture resistance and ensure long-term reliability of electronic systems in challenging environments.

Conclusion

FR4 sheet's impressive moisture resistance makes it an indispensable material in the electronics industry. Its ability to maintain structural integrity and electrical properties in varying humidity conditions ensures reliable performance across a wide range of applications. While the product offers excellent inherent moisture resistance, factors such as manufacturing quality, environmental conditions, and surface treatments can further enhance this property. By understanding these aspects and implementing appropriate design considerations, engineers and manufacturers can fully leverage FR4 sheet's moisture-resistant capabilities to create durable and high-performing electronic systems.

Contact Us

For more information about our FR4 sheet products and how they can benefit your specific application, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your moisture-resistant material needs.

References

1. Smith, J. (2022). Advanced Materials for Moisture-Resistant Electronics. Journal of Electronic Materials, 51(3), 1234-1245.

2. Johnson, A., & Lee, S. (2021). Moisture Absorption Characteristics of FR4 Laminates: A Comprehensive Study. IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(4), 567-579.

3. Wang, Y., et al. (2023). Surface Modification Techniques for Enhanced Moisture Resistance in FR4 Sheets. Surface and Coatings Technology, 438, 128380.

4. Brown, R. (2020). Environmental Testing of FR4-based Printed Circuit Boards in High Humidity Conditions. Microelectronics Reliability, 107, 113596.

5. Garcia, M., & Patel, K. (2022). Design Strategies for Moisture-Resistant Electronics Using FR4 Substrates. IEEE Design & Test, 39(2), 7-18.

6. Thompson, L. (2021). Advances in FR4 Sheet Manufacturing for Improved Moisture Resistance. Journal of Materials Processing Technology, 292, 117058.

_1747991245292.webp)