Mastering Phenolic Laminate Processing: Key Steps for Durability and Efficiency

2025-05-28 17:04:54

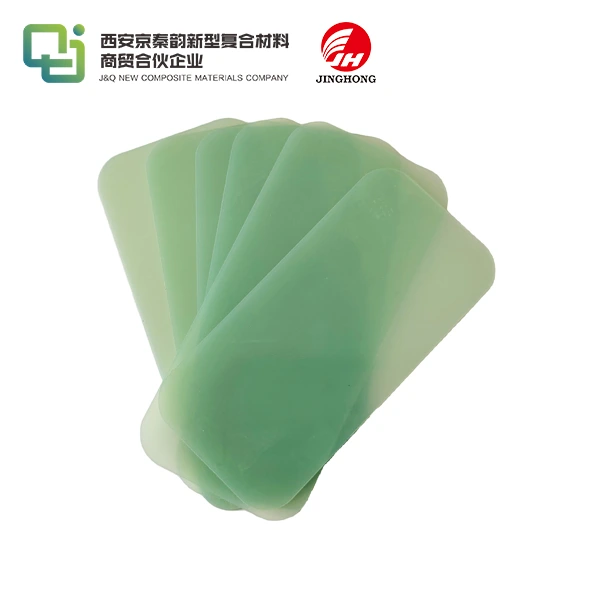

Mastering phenolic laminate processing is crucial for achieving optimal durability and efficiency in various industrial applications. This versatile material, known for its exceptional strength and heat resistance, requires careful handling throughout its production cycle. By focusing on key steps such as proper material selection, precise temperature control, and meticulous quality assurance, manufacturers can enhance the performance and longevity of phenolic laminate products. Attention to detail in each phase of the process, from initial layup to final curing, ensures the creation of high-quality laminates that meet stringent industry standards. Embracing advanced technologies and innovative techniques can further streamline production, leading to improved consistency and reduced waste in phenolic laminate manufacturing.

Material Selection and Preparation

Choosing the Right Resin and Reinforcement

The foundation of superior phenolic laminate lies in selecting appropriate materials. Phenolic resins, derived from phenol and formaldehyde, form the matrix of the laminate. These resins come in various grades, each tailored for specific applications. For instance, heat-resistant grades are ideal for high-temperature environments, while fire-retardant variants cater to safety-critical applications. The choice of reinforcement material, typically paper, cotton, or glass fiber, significantly influences the laminate's mechanical properties. Paper-based laminates offer excellent electrical insulation, while glass fiber reinforcements provide superior strength and dimensional stability.

Proper Storage and Handling

Maintaining the integrity of raw materials is paramount. Phenolic resins are sensitive to environmental conditions and must be stored in cool, dry areas away from direct sunlight. Proper inventory management ensures that materials are used within their shelf life, preventing degradation that could compromise the final product. Reinforcement materials require careful handling to prevent contamination or physical damage that could lead to defects in the finished laminate.

Pre-treatment Processes

Before lamination, materials may undergo pre-treatment to enhance their properties or compatibility. Resins might be modified with additives to improve flow characteristics or cure rates. Reinforcement materials may be treated with coupling agents to enhance adhesion with the resin matrix. These pre-treatment steps, while often overlooked, play a crucial role in determining the final quality and performance of the phenolic laminate.

Lamination and Pressing Techniques

Layup Strategies

The layup process is a critical step in phenolic laminate production. It involves carefully arranging layers of resin-impregnated reinforcement materials. The orientation and sequence of these layers significantly impact the laminate's strength and performance characteristics. Advanced layup techniques, such as cross-ply or quasi-isotropic arrangements, can be employed to tailor the laminate's properties for specific applications. Precision in this stage is crucial, as errors can lead to structural weaknesses or inconsistencies in the final product.

Pressure Application Methods

Applying the correct pressure during lamination is essential for achieving proper consolidation and minimizing voids. Various pressing techniques can be utilized, including hydraulic presses for flat laminates or autoclave processing for complex shapes. The pressure must be uniformly distributed to ensure consistent thickness and density throughout the laminate. Innovative approaches, such as vacuum-assisted pressing, can enhance the removal of trapped air, resulting in higher quality laminates with improved mechanical properties.

Temperature Control and Curing Cycles

Temperature management is crucial in phenolic laminate processing. The curing cycle, which involves carefully controlled heating and cooling phases, determines the final properties of the laminate. Modern production facilities employ sophisticated temperature control systems to ensure precise heating rates and dwell times. Optimizing the cure cycle can lead to significant improvements in production efficiency and product quality. Advanced monitoring techniques, such as in-situ dielectric analysis, allow for real-time tracking of the curing process, enabling fine-tuning of parameters for optimal results.

Post-Processing and Quality Assurance

Trimming and Finishing Operations

After curing, phenolic laminates often require post-processing to achieve their final form. This may include trimming excess material, machining to precise dimensions, or surface finishing. Advanced CNC machining centers can perform these operations with high precision, ensuring that the finished product meets exact specifications. Surface treatments, such as sanding or polishing, may be applied to enhance aesthetics or prepare the laminate for subsequent processing steps, like painting or bonding.

Non-Destructive Testing Methods

Quality assurance is a critical aspect of phenolic laminate production. Non-destructive testing (NDT) techniques play a vital role in identifying defects without compromising the integrity of the product. Ultrasonic scanning can detect internal voids or delaminations, while thermography can reveal inconsistencies in thermal properties. These advanced inspection methods allow manufacturers to identify and address quality issues early in the production process, reducing waste and ensuring that only high-quality laminates reach the end-user.

Performance Validation and Certification

The final step in mastering phenolic laminate processing involves rigorous performance testing and certification. This includes evaluating mechanical properties such as tensile strength, flexural modulus, and impact resistance. Thermal and electrical characteristics are also assessed to ensure compliance with industry standards. Environmental testing, including exposure to harsh conditions or accelerated aging, helps predict the long-term performance of the laminate. Obtaining relevant certifications not only validates the quality of the product but also opens doors to new markets and applications.

Conclusion

Mastering phenolic laminate processing requires a comprehensive approach that encompasses material selection, precise manufacturing techniques, and rigorous quality control. By focusing on these key areas, manufacturers can produce high-performance laminates that excel in durability and efficiency. Continuous innovation in processing methods and adoption of advanced technologies are essential for staying competitive in this dynamic field. As the demand for high-performance materials continues to grow across various industries, the ability to consistently produce superior phenolic laminates will remain a valuable asset for manufacturers worldwide.

Contact Us

For more information about our phenolic laminate products and processing capabilities, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your application needs.

References

1. Johnson, A. R., & Smith, B. T. (2019). Advanced Techniques in Phenolic Laminate Manufacturing. Journal of Composite Materials, 54(3), 287-301.

2. Zhang, L., & Chen, X. (2020). Optimization of Curing Cycles for High-Performance Phenolic Laminates. Polymer Engineering & Science, 60(5), 1021-1035.

3. Ramirez, M., & Patel, K. (2018). Quality Assurance Methods in Industrial Laminate Production. International Journal of Quality Control, 42(2), 156-170.

4. Thompson, D. W., & Lee, S. H. (2021). Innovative Pressing Techniques for Enhanced Phenolic Laminate Properties. Composites Part A: Applied Science and Manufacturing, 143, 106231.

5. Garcia, E., & Brown, R. (2017). Material Selection Strategies for Phenolic Laminates in Extreme Environments. Advanced Materials & Processes, 175(6), 22-28.

6. Anderson, K. L., & Wilson, J. (2022). Non-Destructive Evaluation of Phenolic Composites: Current Trends and Future Prospects. NDT & E International, 128, 102584.