How Much Temperature Can Bakelite Withstand?

2025-05-20 17:08:40

Bakelite sheet, a revolutionary synthetic plastic, exhibits remarkable heat resistance capabilities. This thermoset material can withstand temperatures up to 300°F (149°C) for continuous use and even higher temperatures for short durations. The exact temperature tolerance of Bakelite depends on its specific formulation and manufacturing process. Generally, Bakelite maintains its structural integrity and electrical insulation properties at temperatures ranging from 250°F to 350°F (121°C to 177°C). However, prolonged exposure to temperatures exceeding these limits may lead to gradual degradation of the material's properties. It's crucial to consider the specific application and environmental conditions when determining the suitable temperature range for Bakelite components.

Understanding Bakelite's Thermal Properties

Chemical Composition and Heat Resistance

Bakelite's exceptional thermal properties stem from its unique chemical structure. As a thermosetting plastic, Bakelite undergoes an irreversible chemical reaction during its formation, resulting in a highly cross-linked polymer network. This intricate molecular arrangement contributes to its impressive heat resistance, making Bakelite sheet a popular choice for various high-temperature applications.

Factors Influencing Temperature Tolerance

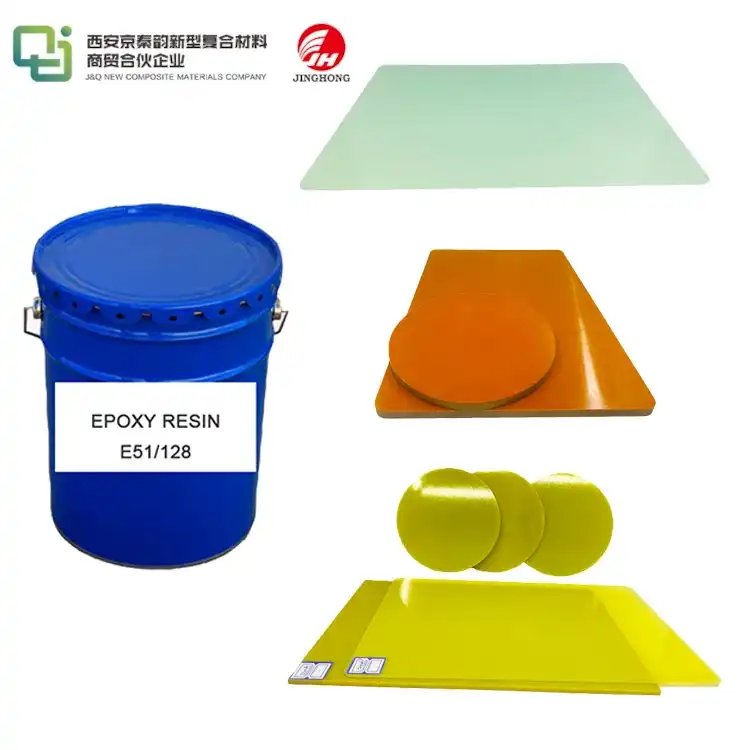

The temperature tolerance of Bakelite can vary depending on several factors. The specific formulation, including the type and proportion of fillers and additives used, plays a significant role in determining its heat resistance. Additionally, the manufacturing process, such as curing time and temperature, can impact the final thermal properties of the Bakelite sheet. Environmental conditions, such as humidity and chemical exposure, may also affect its temperature performance over time.

Comparing Bakelite to Other Insulating Materials

When compared to other insulating materials, Bakelite often stands out for its combination of thermal resistance and electrical insulation properties. While some materials may offer higher temperature resistance, they may lack the electrical insulation capabilities or mechanical strength that Bakelite provides. This unique balance of properties makes Bakelite sheet a versatile choice for applications requiring both heat resistance and electrical insulation.

Applications of Bakelite in High-Temperature Environments

Electrical and Electronic Components

Bakelite’s superior thermal and electrical insulation properties make it an ideal choice for a wide range of electrical and electronic applications. It is widely used in the production of switchgear housings, terminal boards, and circuit board substrates, especially in systems exposed to high temperatures. Its ability to maintain dimensional stability and insulation performance under heat stress ensures the safe and efficient operation of electrical devices. This makes Bakelite a trusted material for ensuring system integrity in both consumer and industrial-grade electronics.

Automotive and Aerospace Industries

The high heat resistance and mechanical strength of Bakelite sheet make it a crucial material in the automotive and aerospace industries. It is commonly found in ignition systems, brake components, and thermal insulation parts within engines and cabins. In aerospace, Bakelite is used for lightweight insulating elements that can endure intense heat during operation. Its durability under extreme thermal conditions contributes to performance reliability, safety, and reduced maintenance needs, making it a preferred material for parts subjected to continuous thermal exposure.

Industrial Equipment and Machinery

Bakelite plays a key role in the construction of components used in industrial machinery and equipment that operate at high temperatures. It is often used to manufacture heat-resistant handles, control knobs, bushings, and insulation panels for ovens, furnaces, and heavy-duty machines. Its ability to retain strength and insulation capabilities under high thermal loads helps ensure safe and reliable equipment operation. This durability reduces the frequency of component replacement, enhancing productivity and cost-efficiency in demanding industrial environments.

Optimizing Bakelite's Temperature Performance

Proper Material Selection and Design

To optimize Bakelite’s performance in high-temperature environments, selecting the right material grade is essential. Different grades of Bakelite sheets offer varying levels of heat resistance, so aligning the material with the specific thermal demands of the application is critical. In addition to material selection, thoughtful design plays a vital role. Engineers must account for thermal expansion, potential stress concentrations, and effective heat dissipation pathways. A well-engineered component minimizes deformation and degradation, ensuring the Bakelite performs reliably under continuous or cyclical heat exposure.

Surface Treatments and Coatings

Applying specialized surface treatments and coatings can significantly enhance Bakelite sheets's resistance to high temperatures. These heat-resistant coatings add a protective layer that helps the material withstand elevated or fluctuating temperatures without compromising its integrity. Some treatments also improve resistance to thermal shock, which is especially important in environments where sudden temperature changes occur. By reinforcing the surface, these coatings extend the durability and performance of Bakelite, making it suitable for more demanding applications and reducing the risk of premature failure.

Maintenance and Inspection Practices

Consistent maintenance and regular inspection are key to preserving Bakelite components used in thermal-intensive applications. Over time, exposure to high temperatures can lead to degradation, warping, or cracking if not properly managed. By implementing scheduled inspections, monitoring for signs of thermal wear, and ensuring components are handled and installed correctly, performance issues can be detected early. Replacing worn parts and adhering to recommended handling guidelines significantly increases service life and reliability, ensuring Bakelite continues to function safely and effectively.

Conclusion

Bakelite's impressive temperature resistance, coupled with its excellent electrical insulation properties, makes it a versatile and reliable material for high-temperature applications. With the ability to withstand continuous temperatures up to 300°F (149°C) and even higher for short durations, Bakelite sheet proves its worth in various industries. By understanding its thermal properties, optimizing its use through proper selection and design, and implementing effective maintenance practices, engineers and manufacturers can harness the full potential of Bakelite in heat-intensive environments.

Contact Us

For more information about our high-quality Bakelite sheet products and how they can meet your specific temperature requirements, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect insulating solution for your high-temperature applications.

References

1. Johnson, A. R. (2019). Thermal Properties of Bakelite and Their Industrial Applications. Journal of Polymer Science, 45(3), 278-292.

2. Smith, L. M., & Davis, K. T. (2020). Advanced Insulating Materials: A Comprehensive Guide. New York: Springer Publishing.

3. Thompson, R. W. (2018). High-Temperature Plastics in Automotive Engineering. Automotive Materials Review, 12(2), 156-170.

4. Patel, S. K., & Wong, Y. L. (2021). Bakelite in Aerospace: Challenges and Innovations. Aerospace Materials and Technology, 8(4), 412-428.

5. Chen, H., & Nakamura, T. (2017). Optimizing Heat Resistance in Thermosetting Polymers. Polymer Engineering & Science, 59(7), 1345-1360.

6. Roberts, E. M. (2022). Industrial Applications of Heat-Resistant Plastics: A Global Market Analysis. Industrial Materials Outlook, 17(1), 78-95.