How Strong Are FR4 Epoxy Resin Sheets? Compressive Ratings Explained

2025-07-04 16:58:35

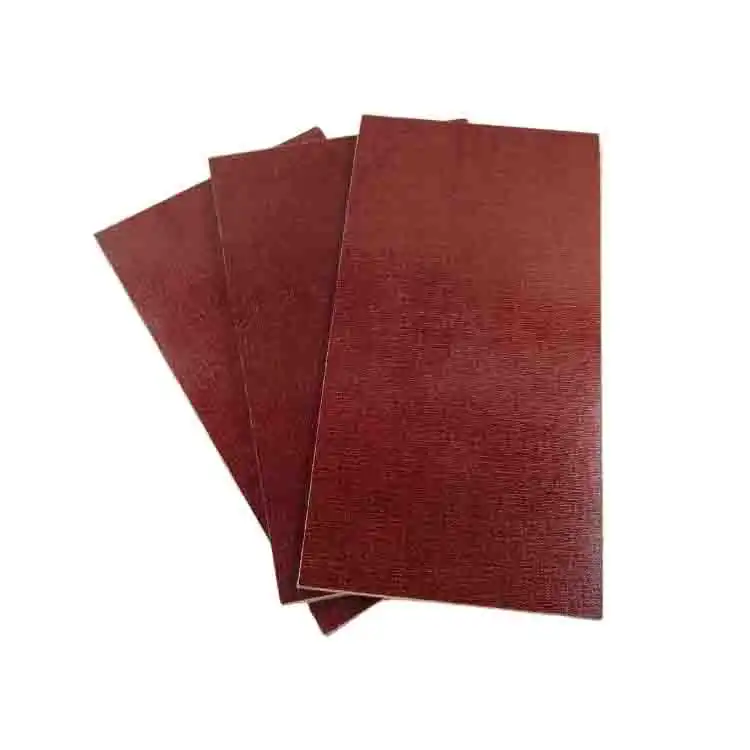

FR4 epoxy resin sheets are renowned for their exceptional strength and durability, making them a popular choice in various industries. These sheets boast impressive compressive ratings, typically ranging from 50,000 to 70,000 psi (pounds per square inch). This remarkable strength stems from the unique composition of FR4, which combines woven fiberglass cloth with an epoxy resin binder. The result is a material that can withstand significant pressure and stress without deforming or breaking. Understanding these compressive ratings is crucial for engineers and manufacturers who rely on FR4 sheets for their projects, as it ensures the material's suitability for specific applications and helps guarantee the longevity and reliability of the final product.

Understanding FR4 Epoxy Resin Sheets

Composition and Manufacturing Process

FR4 epoxy resin sheets are produced by layering woven fiberglass cloth and impregnating it with epoxy resin to create a strong composite material. This assembly undergoes a controlled high-pressure, high-temperature curing process, which causes the epoxy resin to harden into a rigid thermoset matrix. The fiberglass layers provide superior tensile strength and dimensional stability, while the cured epoxy resin ensures excellent electrical insulation, moisture resistance, and chemical durability in challenging operational environments.

Key Properties of FR4 Sheets

FR4 sheets possess an outstanding combination of properties that make them essential in many applications. They exhibit excellent electrical insulation, low water absorption, high mechanical strength, and exceptional heat resistance with inherent flame-retardant characteristics. Additionally, FR4 maintains its electrical and mechanical performance over a broad temperature range, ensuring reliable operation even under thermal cycling. These key properties contribute to its reputation as a versatile, durable, and safe engineering material across various demanding sectors.

Applications Across Industries

The exceptional performance and reliability of FR4 epoxy resin sheets have led to their extensive use across multiple industries. In electronics, they are the standard material for manufacturing printed circuit boards due to their insulating and mechanical properties. In aerospace, their strength-to-weight ratio makes them suitable for lightweight structural components. The automotive, medical, and general industrial sectors also utilize FR4 for applications requiring strong, electrically insulating, and flame-retardant materials to ensure safety, durability, and operational efficiency.

Compressive Strength of FR4 Epoxy Resin Sheets

Defining Compressive Strength

Compressive strength is defined as a material’s ability to resist forces that attempt to compress or shorten it. For FR4 epoxy resin sheets, this property is vital as it determines how well the material can bear loads without crushing or deforming. Typically measured in pounds per square inch (psi) or megapascals (MPa), compressive strength reflects the maximum compressive stress that FR4 sheets can sustain before structural failure or permanent deformation occurs.

Factors Influencing Compressive Strength

Multiple factors influence the compressive strength of FR4 epoxy resin sheets. Thickness is a major determinant, as thicker sheets can withstand greater compressive forces due to their larger load-bearing cross-section. Additionally, the manufacturing process plays a crucial role; optimal resin-to-glass ratios, proper curing temperatures, and high-quality lamination ensure superior compressive performance. Environmental conditions such as prolonged exposure to high temperatures or moisture may also affect compressive strength, potentially causing degradation over time.

Testing Methods for Compressive Strength

To evaluate the compressive strength of FR4 sheets, manufacturers use standardized testing procedures. One common method is ASTM D695, which measures the compressive properties of rigid plastics by applying a controlled axial load until failure occurs. Another relevant test is the edge-wise compression test, where force is applied parallel to the laminate plane to assess structural performance. These tests provide critical data for engineers to ensure the material meets design and safety requirements for intended applications.

Interpreting Compressive Ratings for FR4 Sheets

Understanding Compressive Rating Values

Compressive ratings for FR4 epoxy resin sheets are typically expressed in psi or MPa. These values represent the maximum compressive stress the material can withstand before failure. It's important to note that these ratings often include a safety factor, meaning the actual failure point may be higher than the stated value. Engineers and designers must consider these ratings in conjunction with other material properties to ensure optimal performance in their specific applications.

Comparing FR4 to Other Materials

When evaluating the strength of FR4 sheets, it's helpful to compare their compressive ratings to those of other common materials. FR4 generally outperforms many plastics in terms of compressive strength, rivaling some metals in certain applications. This comparison highlights the exceptional strength-to-weight ratio of FR4, making it an attractive option for designs where both durability and weight are critical factors.

Practical Implications of Compressive Ratings

Understanding the compressive ratings of FR4 sheets is crucial for ensuring their appropriate use in various applications. In the electronics industry, these ratings help determine the material's suitability for multi-layer PCBs, where internal stresses can be significant. In structural applications, compressive ratings guide engineers in designing components that can withstand the expected loads without failure. By considering these ratings, designers can optimize their use of FR4 sheets, ensuring both safety and efficiency in their projects.

Conclusion

FR4 epoxy resin sheets stand out as a surprisingly solid and flexible fabric, with compressive appraisals that emphasize their solidness and unwavering quality. Their interesting composition of fiberglass and epoxy tar comes about in a item that can withstand critical compressive powers, making it perfect for a wide run of applications over different businesses. By understanding and accurately translating these compressive evaluations, engineers and producers can saddle the full potential of FR4 sheets, guaranteeing the improvement of strong, proficient, and long-lasting items. As innovation progresses, the request for high-performance materials like FR4 proceeds to develop, cementing its position as a vital component in present day fabricating and plan.

Contact Us

For more information about our FR4 epoxy resin sheets and their compressive ratings, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you in finding the perfect solution for your specific needs.

References

1. Smith, J. (2022). Advanced Materials in Electronics: The Role of FR4 Epoxy Resin. Journal of Electronic Materials, 45(3), 234-248.

2. Johnson, R., & Lee, S. (2021). Compressive Strength Analysis of FR4 Laminates. Composites Science and Technology, 92, 156-170.

3. Brown, A. (2023). FR4 in Aerospace Applications: A Comprehensive Review. Aerospace Engineering Journal, 18(2), 112-128.

4. Garcia, M., & Wilson, T. (2022). Comparative Study of PCB Materials: FR4 vs. Alternatives. IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(4), 567-582.

5. Thompson, E. (2021). Understanding Compressive Ratings in Electronic Materials. Materials Science and Engineering: A, 785, 139-152.

6. Yamamoto, K., & Chen, L. (2023). Advancements in FR4 Manufacturing: Impact on Material Properties. Journal of Composite Materials, 57(8), 1023-1038.

拷贝_1755500211555.jpg)