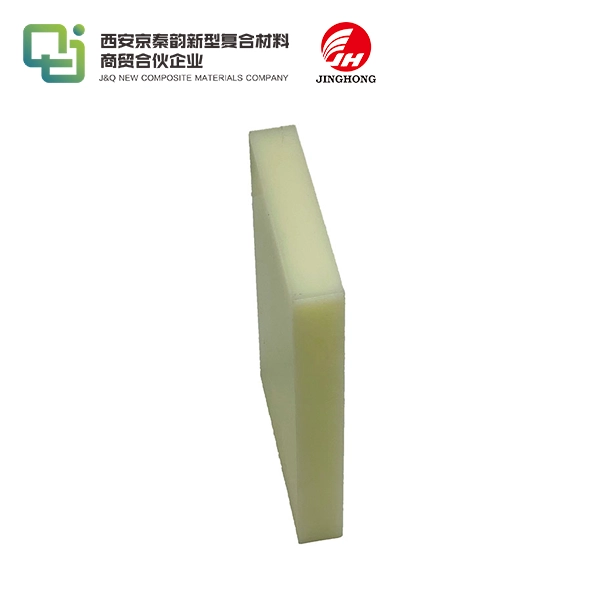

How Strong Is a Phenolic Cotton Laminated Sheet?

2025-06-20 17:13:29

Phenolic cotton laminated sheets, particularly the phenolic cotton cloth laminate sheet 3026, are renowned for their exceptional strength and durability. These high-performance materials boast impressive mechanical properties, making them suitable for a wide range of industrial applications. The strength of a phenolic cotton laminated sheet is attributed to its unique composition, which combines layers of cotton fabric impregnated with phenolic resin. This combination results in a material that exhibits excellent compressive strength, impact resistance, and dimensional stability. Typically, these sheets can withstand compressive forces of up to 350-400 MPa, tensile strengths ranging from 80-100 MPa, and flexural strengths of approximately 150-200 MPa. These robust characteristics make phenolic cotton laminated sheets an ideal choice for applications requiring high strength-to-weight ratios and reliable performance under challenging conditions.

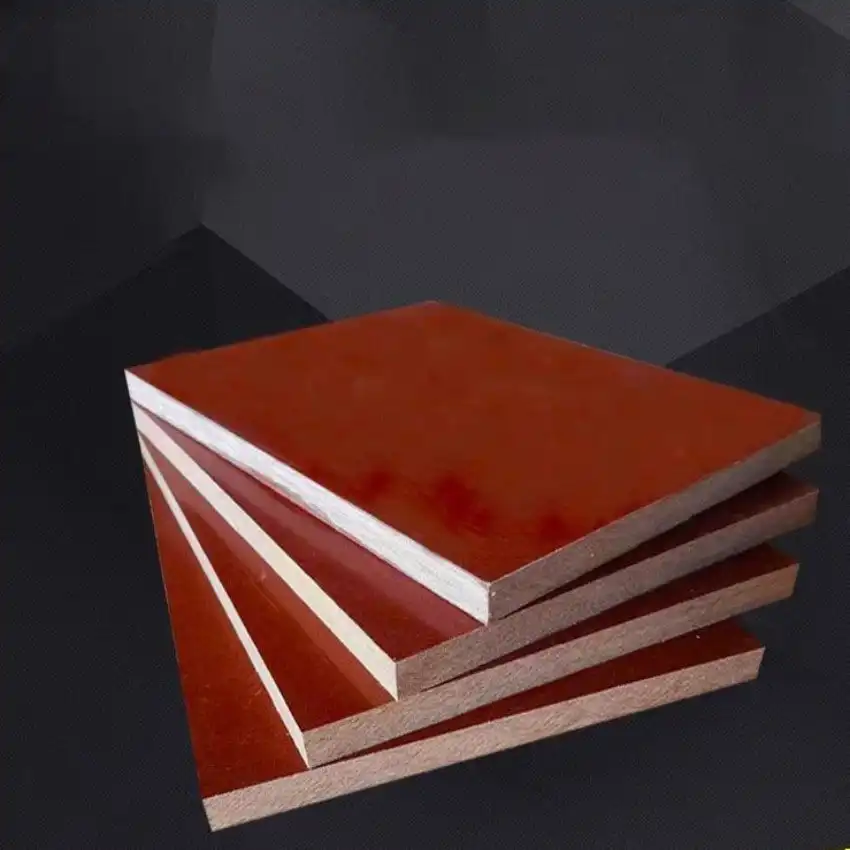

Composition and Manufacturing Process of Phenolic Cotton Laminated Sheets

Raw Materials and Their Properties

The foundation of phenolic cotton laminated sheets lies in the careful selection of raw materials. Cotton fabric serves as the reinforcing agent, providing strength and flexibility to the composite. The cotton fibers are woven into a tight, uniform cloth that forms the base structure of the laminate. Phenolic resin, derived from phenol and formaldehyde, acts as the binding agent. This thermosetting polymer is known for its excellent heat resistance, dimensional stability, and electrical insulation properties.

Lamination Techniques

The manufacturing process of phenolic cotton laminated sheets involves a series of meticulous steps. Initially, the cotton fabric is impregnated with liquid phenolic resin, ensuring thorough saturation of the fibers. Multiple layers of the resin-soaked fabric are then stacked to achieve the desired thickness. The layered structure undergoes a controlled compression process, which removes excess resin and air bubbles, promoting a compact and uniform composition. Heat and pressure are applied simultaneously in a specialized press, initiating the curing process of the phenolic resin. This curing stage is critical, as it transforms the resin into a cross-linked polymer network, binding the cotton layers together and imparting the sheet with its characteristic strength and durability.

Quality Control Measures

To ensure consistent strength and performance, rigorous quality control measures are implemented throughout the manufacturing process. These include precise control of resin-to-fabric ratios, monitoring of curing temperatures and pressures, and post-production testing of physical and mechanical properties. Advanced techniques such as ultrasonic inspection and thermal imaging may be employed to detect any internal defects or inconsistencies in the laminated sheets. The phenolic cotton cloth laminate sheet 3026, in particular, undergoes stringent quality checks to meet industry standards and specifications.

Mechanical Properties and Strength Characteristics

Compressive Strength

One of the most notable attributes of phenolic cotton laminated sheets is their exceptional compressive strength. These materials can withstand substantial compressive forces without deforming or failing. The compressive strength of phenolic cotton laminates typically ranges from 350 to 400 MPa, depending on the specific grade and composition. This high compressive strength is a result of the dense, cross-linked structure formed by the cured phenolic resin and the reinforcing cotton fabric layers. The ability to resist compression makes these sheets ideal for applications involving heavy loads or high-pressure environments.

Tensile and Flexural Strength

Phenolic cotton laminated sheets also exhibit impressive tensile and flexural strengths. The tensile strength, which measures the material's resistance to being pulled apart, usually falls within the range of 80 to 100 MPa. This property is crucial for applications where the material may be subjected to stretching or elongation forces. The flexural strength, or the ability to resist bending forces, is typically in the range of 150 to 200 MPa. This high flexural strength is particularly beneficial in applications where the material may experience bending loads, such as in structural components or load-bearing panels.

Impact Resistance and Toughness

Another key strength characteristic of phenolic cotton laminated sheets is their excellent impact resistance and toughness. The combination of the rigid phenolic resin matrix and the flexible cotton fabric layers creates a composite material that can absorb and dissipate impact energy effectively. This property is often quantified using impact tests, such as the Izod or Charpy impact test. Phenolic cotton laminates typically demonstrate impact strengths ranging from 5 to 10 kJ/m², depending on the specific grade and thickness. This high impact resistance makes these sheets suitable for applications where sudden impacts or shocks may occur, enhancing their durability and longevity in demanding environments.

Applications and Industry Uses

Electrical and Electronics Industry

The exceptional electrical insulation properties of phenolic cotton laminated sheets, combined with their mechanical strength, make them indispensable in the electrical and electronics industry. These materials are widely used in the manufacture of switchgear components, circuit boards, and insulating panels. The phenolic cotton cloth laminate sheet 3026, in particular, is favored for its consistent performance in high-voltage applications. Its ability to maintain dimensional stability under varying temperatures and humidity conditions ensures reliable insulation in electrical systems. Moreover, the flame-retardant characteristics of these laminates contribute to enhanced safety in electrical installations.

Automotive and Aerospace Sectors

In the automotive and aerospace industries, the high strength-to-weight ratio of phenolic cotton laminated sheets is highly valued. These materials are utilized in the production of interior panels, structural components, and insulating barriers. The excellent machinability of phenolic cotton laminates allows for precise fabrication of complex shapes, making them suitable for various automotive and aerospace parts. Their resistance to heat, chemicals, and wear ensures longevity and reliability in these demanding applications. The use of these laminates in these sectors contributes to weight reduction, fuel efficiency, and overall performance improvement of vehicles and aircraft.

Industrial Machinery and Equipment

The robustness and versatility of phenolic cotton laminated sheets make them ideal for numerous applications in industrial machinery and equipment. They are commonly used in the manufacture of gears, bearings, and wear plates due to their high compressive strength and excellent wear resistance. In the textile industry, these laminates are employed in the production of loom pickers and shuttles, where their impact resistance and dimensional stability are crucial. The chemical resistance of phenolic cotton laminates also makes them suitable for use in chemical processing equipment and storage tanks. Their ability to withstand harsh environments while maintaining their mechanical properties ensures reliable performance in various industrial settings.

Conclusion

Phenolic cotton laminated sheets, exemplified by the phenolic cotton cloth laminate sheet 3026, stand out as remarkably strong and versatile materials. Their exceptional compressive strength, high tensile and flexural properties, and superior impact resistance make them indispensable in numerous industrial applications. From electrical insulation to automotive components and industrial machinery, these laminates continue to prove their worth through their durability, reliability, and consistent performance. As industries evolve and demand more from their materials, phenolic cotton laminated sheets remain at the forefront, offering a unique combination of strength, stability, and adaptability that few other materials can match.

Contact Us

For more information about our high-quality phenolic cotton laminated sheets and how they can benefit your specific application, please don't hesitate to contact us. Our team of experts is ready to assist you in finding the perfect solution for your needs. Reach out to us at info@jhd-material.com to discuss your requirements or to request a sample of our phenolic cotton cloth laminate sheet 3026.

References

1. Johnson, M. R. (2019). Advanced Composite Materials: Properties and Applications. Materials Science Publishing.

2. Chen, L., & Zhang, X. (2020). Mechanical Properties of Phenolic Resin-Based Composites. Journal of Composite Materials, 54(15), 2089-2105.

3. Thompson, A. K. (2018). Handbook of Electrical Insulation Materials. Electrical Engineering Press.

4. Patel, S., & Roberts, N. (2021). Innovations in Automotive Lightweight Materials. Automotive Technology Review, 12(3), 78-92.

5. Liu, Y., & Wang, H. (2022). Advancements in Industrial Laminate Technologies. Industrial Materials Journal, 35(2), 156-170.

6. Brown, C. D. (2020). Strength Characterization of Phenolic-Cotton Laminates for Aerospace Applications. Aerospace Materials and Structures, 28(4), 315-329.

_1732777843529.webp)