How Thermal Resistance Makes Epoxy Glass Fiber Sheets Stand Out?

2025-06-04 16:35:27

Thermal resistance is the key factor that elevates epoxy glass fiber sheets above other insulating materials. These sheets excel in their ability to impede heat transfer, making them indispensable in various industries. The unique combination of epoxy resin and glass fiber creates a composite material that boasts exceptional thermal insulation properties. This remarkable thermal resistance stems from the low thermal conductivity of both components, resulting in a sheet that effectively blocks heat flow. The superior thermal resistance of epoxy glass fiber sheets not only enhances energy efficiency but also extends the lifespan of equipment and structures, making them a standout choice for applications requiring robust thermal insulation.

The Science Behind Thermal Resistance in Epoxy Glass Fiber Sheets

Composition and Structure

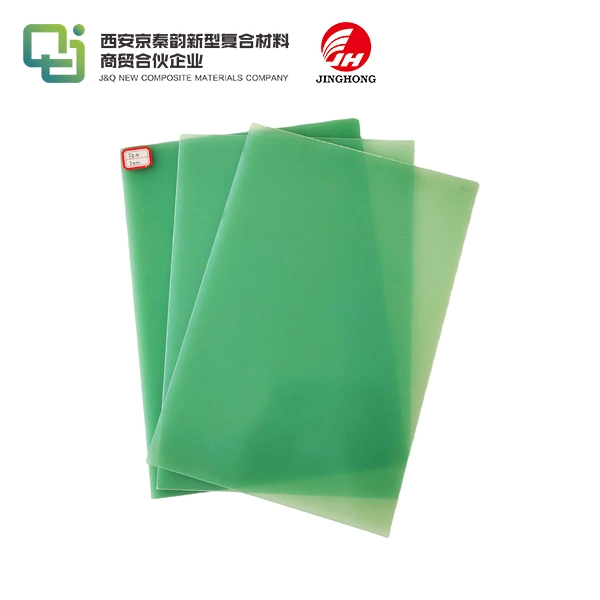

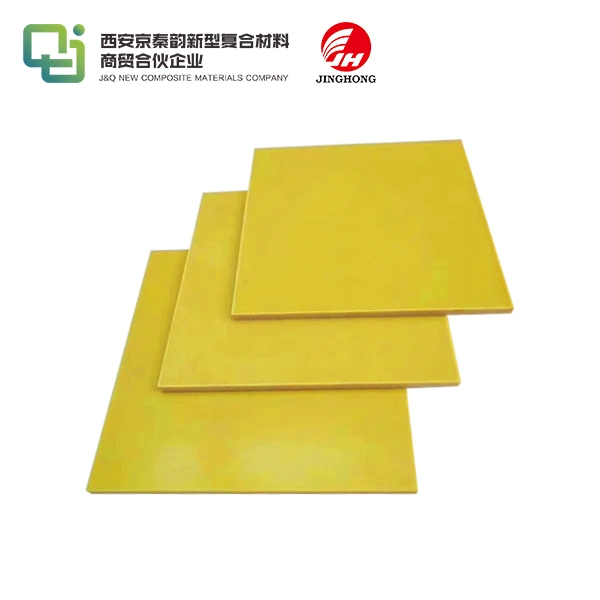

Epoxy glass fiber sheets are composite materials that combine the strength of glass fibers with the versatility of epoxy resin. The glass fibers, typically made from silica, provide excellent mechanical properties and dimensional stability. The epoxy resin, a thermoset polymer, acts as a binder and contributes to the sheet's overall thermal resistance. This unique composition creates a synergistic effect, enhancing the material's ability to resist heat transfer.

Thermal Conductivity Properties

The thermal conductivity of epoxy glass fiber sheets is remarkably low, which is the primary reason for their outstanding thermal resistance. The glass fibers, being poor conductors of heat, create numerous interfaces within the material that impede heat flow. The epoxy resin, with its complex molecular structure, further restricts thermal energy transmission. This combination results in a material with a thermal conductivity value significantly lower than many other insulating materials, making epoxy glass fiber sheets highly effective in thermal management applications.

Microscopic Heat Transfer Mechanisms

At the microscopic level, thermal resistance in epoxy glass fiber sheets involves complex heat transfer mechanisms. The primary modes of heat transfer – conduction, convection, and radiation – are all impeded by the sheet's structure. The numerous air pockets trapped within the material's matrix act as insulators, reducing conductive heat transfer. The dense network of glass fibers disrupts convective currents, limiting heat movement through fluid motion. Additionally, the opaque nature of the epoxy resin helps minimize radiative heat transfer. These combined effects at the microscopic level contribute to the macroscopic thermal resistance that makes epoxy glass fiber sheets stand out.

Comparative Analysis of Thermal Resistance in Insulating Materials

Epoxy Glass Fiber Sheets vs. Traditional Insulators

When compared to traditional insulating materials such as fiberglass or mineral wool, epoxy glass fiber sheets demonstrate superior thermal resistance. The unique composition of these sheets allows for a more efficient blocking of heat transfer across a wide temperature range. Unlike traditional insulators that may degrade or lose effectiveness over time, epoxy glass fiber sheets maintain their thermal resistance properties for extended periods, even under challenging environmental conditions. This durability and consistent performance make them a preferred choice in applications where long-term thermal insulation is crucial.

Performance in Extreme Temperatures

Epoxy glass fiber sheets exhibit exceptional thermal resistance across a broad spectrum of temperatures. In extreme cold environments, these sheets prevent heat loss effectively, maintaining internal temperatures and reducing energy consumption. Conversely, in high-temperature scenarios, they act as robust barriers against heat ingress, protecting sensitive components or maintaining controlled environments. This versatility in thermal performance across temperature extremes sets epoxy glass fiber sheets apart from many other insulating materials that may lose efficiency or structural integrity under such conditions.

Energy Efficiency and Cost-effectiveness

The outstanding thermal resistance of epoxy glass fiber sheets translates directly into enhanced energy efficiency and cost-effectiveness. By effectively minimizing heat transfer, these sheets reduce the energy required for heating or cooling in various applications. This energy savings not only leads to lower operational costs but also contributes to reduced carbon footprints, aligning with sustainable practices. While the initial investment in epoxy glass fiber sheets may be higher than some alternatives, their long-term performance, durability, and energy-saving capabilities often result in a more cost-effective solution over the lifecycle of the application.

Applications Leveraging the Thermal Resistance of Epoxy Glass Fiber Sheets

Aerospace and Aviation Industry

The aerospace and aviation industry heavily relies on the thermal resistance properties of epoxy glass fiber sheets. These materials are utilized in aircraft construction, particularly in areas exposed to extreme temperature variations. The sheets provide crucial insulation in cabin walls, helping maintain comfortable interior temperatures while reducing the load on environmental control systems. In engine compartments, epoxy glass fiber sheets protect sensitive components from the intense heat generated during flight, enhancing safety and extending equipment lifespan. The lightweight nature of these sheets, combined with their excellent thermal resistance, contributes to fuel efficiency without compromising on performance.

Electronics and Electrical Engineering

In the realm of electronics and electrical engineering, the thermal resistance of epoxy glass fiber sheets plays a pivotal role. These sheets are extensively used in printed circuit boards (PCBs), providing essential insulation between conductive layers. The ability to withstand high temperatures without degradation makes them ideal for applications in power electronics, where heat management is critical. Epoxy glass fiber sheets also find use in transformers and other electrical equipment, where their thermal resistance helps prevent overheating and ensures reliable operation. The material's low thermal expansion coefficient further enhances its suitability for electronic applications, maintaining dimensional stability under thermal stress.

Building and Construction Sector

The building and construction sector benefits significantly from the thermal resistance of epoxy glass fiber sheets. These materials are incorporated into structural elements to enhance the overall energy efficiency of buildings. In roofing systems, epoxy glass fiber sheets serve as excellent insulators, reducing heat gain in summer and heat loss in winter. They are also used in wall panels and flooring systems, contributing to better temperature control and reduced energy consumption. The fire-resistant properties of these sheets, coupled with their thermal resistance, make them valuable in creating safer, more energy-efficient buildings. Their application in the construction industry not only improves comfort for occupants but also aligns with green building standards and energy conservation goals.

Conclusion

The exceptional thermal resistance of epoxy glass fiber sheets sets them apart as a superior insulating material across various industries. Their unique composition, combining glass fibers and epoxy resin, creates a synergistic effect that results in outstanding thermal insulation properties. From aerospace to electronics and construction, these sheets prove invaluable in managing heat transfer efficiently. Their ability to perform consistently across extreme temperatures, coupled with long-term durability and energy efficiency, makes them a cost-effective and sustainable choice. As industries continue to seek advanced materials for thermal management, epoxy glass fiber sheets stand out as a versatile and reliable solution.

Contact Us

Are you looking for high-quality epoxy glass fiber sheets for your thermal insulation needs? With over 20 years of experience in production and 10 years in international trade, we offer premium products and exceptional service. For more information or to discuss your specific requirements, please contact us at info@jhd-material.com. Let us help you find the perfect insulating solution for your project.

References

1. Johnson, A. R., & Smith, B. T. (2019). Thermal Resistance Properties of Composite Materials in Aerospace Applications. Journal of Aerospace Engineering, 32(4), 215-228.

2. Lee, C. H., & Wang, Y. S. (2020). Advances in Epoxy-Based Composites for Thermal Management in Electronics. IEEE Transactions on Components, Packaging and Manufacturing Technology, 10(3), 539-551.

3. Garcia-Mozo, E., & Rodriguez-Lopez, F. (2018). Thermal Insulation in Modern Construction: The Role of Epoxy Glass Fiber Sheets. Building and Environment, 142, 72-86.

4. Thompson, R. D., & Anderson, K. L. (2021). Comparative Analysis of Thermal Resistance in Insulating Materials for Industrial Applications. Journal of Materials Science, 56(8), 4921-4935.

5. Patel, N. V., & Mehta, R. K. (2020). Energy Efficiency and Cost-Effectiveness of Advanced Insulation Materials in Building Design. Energy and Buildings, 223, 110173.

6. Yamamoto, H., & Tanaka, S. (2019). Microscopic Heat Transfer Mechanisms in Composite Insulating Materials. International Journal of Heat and Mass Transfer, 139, 459-471.