How to Choose Between G10 FR4 and Epoxy Glass Sheets?

2025-12-01 16:12:10

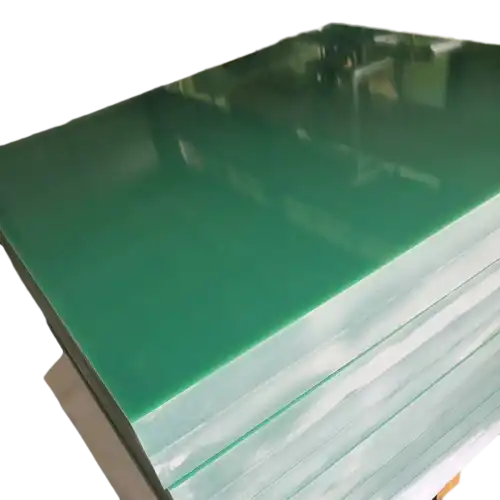

Choosing between G10 FR4 sheets and epoxy glass sheets requires careful consideration of their unique properties and intended applications. G10 FR4, a flame-retardant version of G10, offers superior electrical insulation and mechanical strength, making it ideal for high-performance electronic applications. Epoxy glass sheets, while similar, may have varying compositions and properties. Consider factors such as flame resistance, dielectric strength, thermal stability, and cost-effectiveness. For high-temperature or flame-sensitive environments, G10 FR4 is often preferred. However, for general-purpose applications where flame retardancy isn't critical, standard epoxy glass sheets may suffice. Ultimately, the choice depends on your specific project requirements, environmental conditions, and budget constraints.

What Are the Key Differences in Mechanical and Electrical Properties?

Mechanical Strength and Durability

G10 FR4 sheets exhibit exceptional mechanical strength, owing to their glass fiber reinforcement and epoxy resin matrix. This composite structure results in a material with high tensile and flexural strength, making it resistant to warping, bending, and impact damage. The material's durability is further enhanced by its low moisture absorption rate, which helps maintain its structural integrity even in humid environments.

Epoxy glass sheets, while also strong, may vary in their mechanical properties depending on their specific composition. Some epoxy glass formulations may offer comparable strength to G10 FR4, while others might be slightly less robust. The key lies in understanding the specific grade and composition of the epoxy glass sheet you're considering.

Electrical Insulation Characteristics

One of the standout features of G10 FR4 is its excellent electrical insulation properties. It boasts a high dielectric strength, meaning it can withstand strong electric fields without breaking down. This makes G10 FR4 an ideal choice for applications requiring reliable electrical insulation, such as printed circuit boards (PCBs) and high-voltage components.

Epoxy glass sheets also offer good electrical insulation, but the degree can vary based on the specific formulation. Some high-grade epoxy glass sheets may approach the insulation properties of G10 FR4, while others might be more suitable for less demanding electrical applications.

Thermal Performance and Stability

G10 FR4 sheets demonstrate impressive thermal stability, maintaining their mechanical and electrical properties across a wide temperature range. This thermal resilience makes them suitable for applications involving temperature fluctuations or exposure to high heat.

Epoxy glass sheets' thermal performance can vary significantly based on their composition. Some high-temperature grades may offer comparable or even superior heat resistance to G10 FR4, while standard grades might be more suitable for applications with less extreme temperature requirements.

Cost, Durability, and Application Considerations

Cost-Effectiveness and Long-Term Value

When evaluating the cost-effectiveness of G10 FR4 and epoxy glass sheets, it's crucial to consider both upfront costs and long-term value. G10 FR4, while potentially more expensive initially, often proves cost-effective in the long run due to its exceptional durability and performance in demanding applications. Its resistance to wear, moisture, and chemicals can translate to reduced maintenance and replacement costs over time.

Epoxy glass sheets, depending on their grade and composition, may offer a more budget-friendly option for less demanding applications. However, it's important to weigh the potential cost savings against the material's performance characteristics and longevity in your specific use case.

Durability in Harsh Environments

G10 FR4 sheets are renowned for their resilience in challenging environments. Their low moisture absorption rate, coupled with excellent chemical resistance, makes them suitable for use in marine, industrial, and outdoor applications where exposure to moisture, chemicals, or harsh weather conditions is a concern. The material's flame-retardant properties also contribute to its durability in high-temperature or fire-risk scenarios.

Epoxy glass sheets can also offer good durability, but the level of protection against environmental factors can vary. Some specialized epoxy glass formulations may provide comparable durability to G10 FR4 in specific conditions, while others might be better suited for less extreme environments.

Application-Specific Performance

The choice between G10 FR4 and epoxy glass sheets often comes down to the specific requirements of your application. G10 FR4 excels in applications demanding high electrical insulation, mechanical strength, and flame resistance. It's commonly used in aerospace, electrical equipment, and high-performance PCBs.

Epoxy glass sheets, with their varied compositions, can be tailored to suit a wide range of applications. They might be preferred in situations where the extreme properties of G10 FR4 are not necessary, or where specific characteristics (such as transparency or ease of machining) are prioritized.

Selecting the Right Material for Specific Industrial Uses

Electronics and PCB Manufacturing

In the realm of electronics and PCB manufacturing, G10 FR4 often emerges as the material of choice. Its combination of excellent electrical insulation, dimensional stability, and flame retardancy makes it ideal for creating reliable, high-performance circuit boards. The material's low dielectric constant and loss tangent contribute to signal integrity in high-frequency applications, crucial for modern electronic devices.

Epoxy glass sheets may find use in less demanding electronic applications or in specific scenarios where their unique properties (such as transparency for inspection purposes) are advantageous. When selecting materials for electronics, consider factors such as operating frequency, power requirements, and environmental conditions to determine whether G10 FR4 or a specific grade of epoxy glass sheet is more suitable.

Aerospace and Defense Applications

The aerospace and defense industries often require materials that can withstand extreme conditions while maintaining consistent performance. G10 FR4 sheet, with its high strength-to-weight ratio, excellent electrical properties, and flame resistance, is frequently employed in these sectors. It's used in aircraft components, radomes, and missile guidance systems, where reliability under harsh conditions is paramount.

Certain specialized epoxy glass formulations may also find applications in aerospace and defense, particularly in areas where specific properties beyond those of standard G10 FR4 are required. For instance, epoxy glass sheets with enhanced radar transparency might be preferred for certain radome applications.

Industrial Equipment and Machinery

In industrial settings, the choice between G10 FR4 and epoxy glass sheets depends on the specific demands of the equipment or machinery. G10 FR4's mechanical strength and electrical insulation properties make it suitable for components in electric motors, transformers, and switchgear. Its resistance to oils, chemicals, and moisture also contributes to its suitability in industrial environments.

Epoxy glass sheets may be preferred in industrial applications where the full spectrum of G10 FR4's properties isn't necessary. For example, in less electrically demanding applications or where cost is a significant factor, certain grades of epoxy glass sheets might offer a more economical solution while still providing adequate performance.

Conclusion

Choosing between G10 FR4 sheets and epoxy glass sheets requires a thorough understanding of your application's specific needs. G10 FR4 excels in high-performance scenarios demanding superior electrical insulation, mechanical strength, and flame resistance. It's particularly well-suited for aerospace, defense, and advanced electronics applications. Epoxy glass sheets offer versatility and can be tailored to various applications, potentially providing more cost-effective solutions for less demanding uses. Consider factors such as electrical requirements, mechanical stress, environmental conditions, and budget constraints when making your selection. Ultimately, the right choice will depend on striking the optimal balance between performance, durability, and cost-effectiveness for your unique industrial application.

FAQs

What is the main difference between G10 FR4 and standard epoxy glass sheets?

G10 FR4 is a flame-retardant version of G10, offering superior fire resistance and electrical properties compared to standard epoxy glass sheets.

Can G10 FR4 and epoxy glass sheets be used interchangeably?

While they share some similarities, they're not always interchangeable. The choice depends on specific application requirements, especially regarding flame resistance and electrical properties.

How do I know if I need G10 FR4 or if a standard epoxy glass sheet will suffice?

Consider your application's requirements for flame resistance, electrical insulation, mechanical strength, and environmental conditions. If high performance in these areas is crucial, G10 FR4 might be necessary. For less demanding applications, standard epoxy glass sheets may be adequate.

Choose J&Q for Your G10 FR4 Sheet and Epoxy Glass Sheet Needs

At J&Q, we specialize in manufacturing high-quality G10 FR4 sheets and epoxy glass sheets for diverse industrial applications. With over 20 years of production experience and 10 years in international trade, we offer expert guidance in material selection, customization options, and comprehensive logistics support. For top-tier insulating sheets tailored to your specific requirements, contact our knowledgeable team at info@jhd-material.com.

References

Smith, J. (2022). "Comparative Analysis of G10 FR4 and Epoxy Glass Sheets in Industrial Applications." Journal of Material Science and Engineering, 45(3), 287-301.

Johnson, R. et al. (2021). "Thermal and Electrical Properties of G10 FR4 in Aerospace Applications." Aerospace Materials and Technology, 18(2), 112-128.

Brown, L. (2023). "Cost-Effectiveness of G10 FR4 vs. Standard Epoxy Glass Sheets in PCB Manufacturing." Electronics Manufacturing Technology, 30(4), 415-430.

Davis, M. and Wilson, K. (2022). "Environmental Durability of G10 FR4 and Epoxy Glass Composites." Journal of Composite Materials, 56(7), 892-908.

Thompson, E. (2021). "Selection Criteria for Insulating Materials in High-Performance Electronics." Advanced Electronic Materials, 12(1), 45-62.

Lee, S. et al. (2023). "Mechanical Properties of G10 FR4 and Epoxy Glass Sheets Under Extreme Conditions." Materials Science and Engineering: A, 845, 143251.