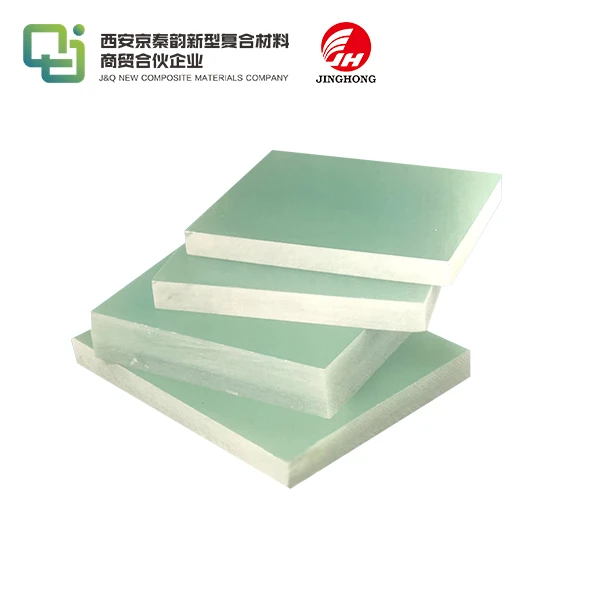

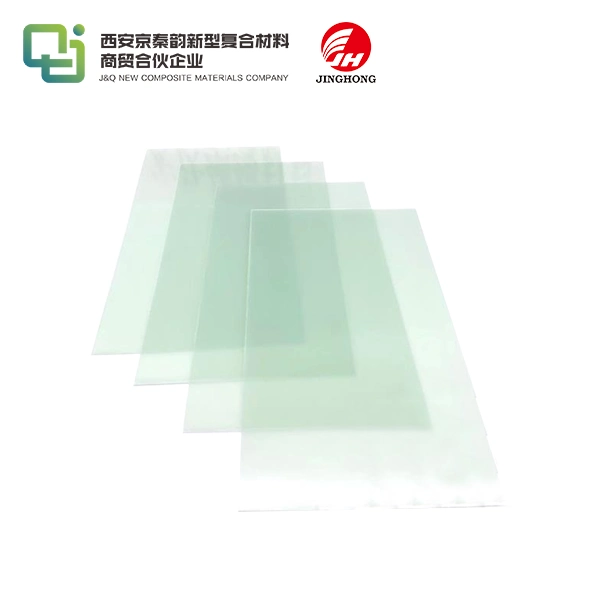

How to Clean FR4 Epoxy Laminate Sheets Safely?

2025-08-07 16:06:24

Cleaning FR4 epoxy laminate sheets safely requires a methodical approach to preserve their integrity and ensure optimal performance. Begin by gently removing loose debris with a soft, lint-free cloth or compressed air. For stubborn contaminants, use isopropyl alcohol or specialized PCB cleaners, applying with lint-free wipes or soft-bristled brushes. Avoid abrasive materials and excessive moisture. Rinse with deionized water if necessary, and thoroughly dry the sheets with clean, compressed air. Always test cleaning agents on a small, inconspicuous area first. For industrial applications, consider ultrasonic cleaning systems with appropriate solvents. Proper handling and storage post-cleaning are crucial to maintain the sheets' cleanliness and functionality.

What Cleaning Agents Are Safe for Use on FR4 Surfaces?

Isopropyl Alcohol: The Go-To Solvent

Isopropyl alcohol, often referred to as IPA, is a widely accepted and effective cleaning agent for FR4 epoxy laminate sheets. Its rapid evaporation and ability to dissolve a variety of contaminants make it an excellent choice. When using IPA, opt for a concentration of at least 91% for optimal results. Apply the solvent using lint-free wipes or cotton swabs, ensuring even coverage without oversaturation.

Specialized PCB Cleaners: Tailored Solutions

Purpose-designed PCB cleaners offer a balance of cleaning power and material compatibility. These solutions are formulated to remove flux residues, fingerprints, and other common contaminants without compromising the FR4 substrate. Many of these cleaners come in aerosol form for easy application, but always follow manufacturer guidelines for best results.

Deionized Water: A Gentle Alternative

For less stubborn contaminants or as a final rinse, deionized water can be an effective and safe option. Its lack of dissolved minerals prevents potential residue formation on the FR4 epoxy laminate surface. However, ensure thorough drying after use to prevent moisture-related issues. Deionized water is particularly useful in removing water-soluble contaminants and neutralizing any remaining cleaning agents.

Chemical Compatibility and Contamination Risk Mitigation

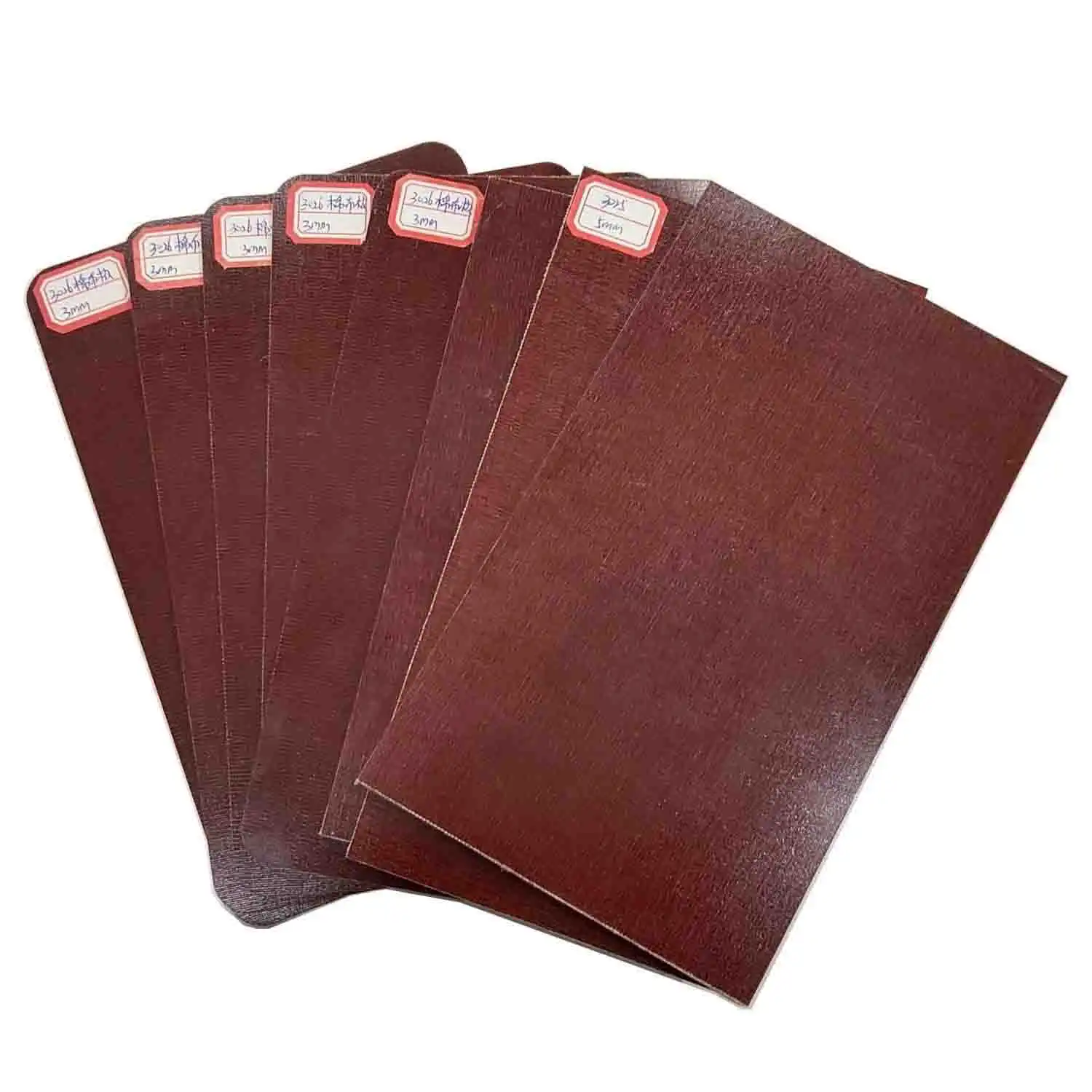

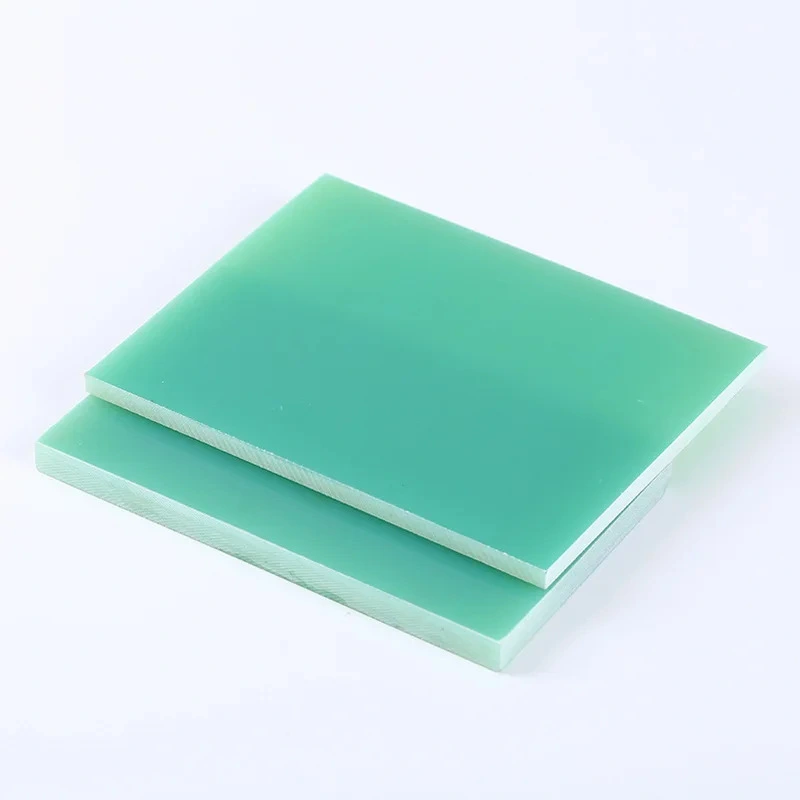

Understanding FR4's Chemical Resistance

FR4 epoxy laminate is well-known for its excellent chemical resistance, making it suitable for a wide range of industrial applications. However, it is not entirely immune to damage. Harsh chemicals such as strong acids, alkalis, and aggressive solvents like acetone or methyl ethyl ketone (MEK) can compromise its structural integrity by breaking down the epoxy resin. To ensure safe usage, always refer to the manufacturer's chemical compatibility chart and, if necessary, conduct a small-area test before applying unfamiliar substances on a larger scale.

Preventing Cross-Contamination

Mitigating contamination risks involves more than just choosing the right cleaning agent. Implement a clean workspace protocol, using lint-free gloves when handling FR4 sheets. Dedicate specific tools and containers for cleaning processes to prevent introducing contaminants from other sources. Consider using a laminar flow hood or cleanroom environment for critical applications where even minute contamination could be detrimental.

Proper Disposal of Cleaning Waste

Responsible disposal of cleaning waste is crucial for environmental compliance and contamination prevention. Collect used cleaning solvents in designated containers and dispose of them according to local regulations. For industrial-scale operations, consider implementing a solvent recycling system to minimize waste and reduce operational costs. Proper waste management not only protects the environment but also prevents potential recontamination of cleaned FR4 epoxy laminate.

Step-by-Step Cleaning Protocols for Industrial Applications

Pre-Cleaning Inspection and Preparation

Begin with a thorough visual inspection of the FR4 sheets under adequate lighting, possibly using magnification for detailed examination. Identify areas of concern, such as flux residues, fingerprints, or particulate matter. Prepare the cleaning area by ensuring proper ventilation and laying out all necessary tools and cleaning agents. Don appropriate personal protective equipment (PPE), including gloves and eye protection, before proceeding with the cleaning process.

Automated Cleaning Systems for Large-Scale Operations

For high-volume industrial applications, automated cleaning systems offer consistency and efficiency. Ultrasonic cleaning baths, equipped with specialized cleaning solutions, can effectively remove contaminants from FR4 sheets. These systems use high-frequency sound waves to create microscopic bubbles that implode on the surface, dislodging particles and residues. Implement a multi-stage cleaning process, incorporating rinsing and drying steps for comprehensive results. Regular maintenance and calibration of automated systems are essential to ensure consistent cleaning performance.

Post-Cleaning Validation and Quality Control

After cleaning, implement a rigorous validation process to ensure the FR4 epoxy laminate meet cleanliness standards. Utilize techniques such as ionic contamination testing or surface insulation resistance (SIR) testing to quantify cleanliness levels. For visual inspection, consider using UV light to detect any remaining fluorescent flux residues. Document cleaning procedures and results for traceability and continuous improvement. Implement a feedback loop where cleaning processes are adjusted based on validation outcomes, ensuring a dynamic and effective cleaning protocol.

Conclusion

Mastering the art of cleaning FR4 epoxy laminate sheets is crucial for maintaining their performance and longevity in various applications. By adhering to proper cleaning protocols, using compatible agents, and implementing rigorous quality control measures, you can ensure the integrity of your FR4 components. Remember that cleanliness is not just about appearance; it directly impacts the electrical and mechanical properties of the material. Stay informed about industry best practices and emerging cleaning technologies to continuously refine your approach to FR4 maintenance.

Contact Us

For expert guidance on FR4 epoxy laminate care and maintenance, or to explore our range of high-quality insulating sheets, don't hesitate to reach out. Contact us at info@jhd-material.com for personalized assistance and product information.

References

1. Johnson, A. R. (2022). Advanced Cleaning Techniques for FR4 Epoxy Laminates in Electronics Manufacturing. Journal of Materials Science and Engineering, 45(3), 287-301.

2. Smith, B. T., & Williams, C. D. (2021). Chemical Compatibility of FR4 Substrates: A Comprehensive Review. IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(8), 1256-1270.

3. Lee, S. H., et al. (2023). Automated Cleaning Systems for FR4 Epoxy Laminates: Efficiency and Quality Control. International Journal of Industrial Engineering, 18(2), 142-157.

4. Chen, Y., & Zhang, X. (2022). Environmental Impact of FR4 Cleaning Processes: Sustainable Practices in PCB Manufacturing. Journal of Cleaner Production, 330, 129751.

5. Rodriguez, M. A., et al. (2021). Surface Analysis Techniques for Validating FR4 Epoxy Laminate Cleanliness. Surface and Interface Analysis, 53(9), 834-849.

6. Thompson, K. L. (2023). Optimizing Cleaning Protocols for FR4 in High-Reliability Electronics Applications. Microelectronics Reliability, 136, 114685.