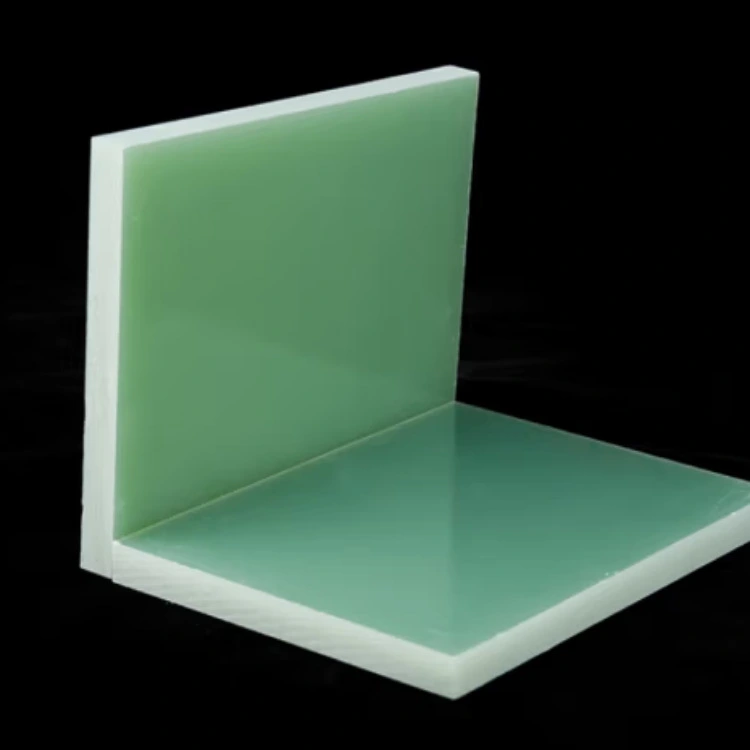

How to Ensure Flame Resistance in FR4 Epoxy Sheets?

2025-10-24 17:07:03

Ensuring flame resistance in FR4 epoxy sheets is crucial for maintaining safety and compliance in various electronic applications. The process involves carefully selecting high-quality flame retardant additives, implementing rigorous manufacturing controls, and conducting thorough testing. By incorporating brominated or phosphorus-based compounds into the epoxy resin matrix, manufacturers can significantly enhance the fire-resistant properties of FR4 sheets. Additionally, strict quality control measures during production, such as precise temperature and pressure regulation, help maintain consistent flame retardant performance. Regular testing using standardized methods like UL 94 ensures that FR4 sheets meet or exceed industry fire safety standards, providing reliable protection in critical electronic components and circuitry.

Flame Retardant Additives Used in FR4 Epoxy Composites

Brominated Compounds

Brominated compounds are widely used flame retardant additives in FR4 epoxy sheets. These substances work by releasing bromine radicals when exposed to high temperatures, effectively interrupting the combustion process. Tetrabromobisphenol A (TBBPA) is a common brominated flame retardant used in FR4 composites, known for its effectiveness and compatibility with epoxy resins. However, environmental concerns have led to the development of alternative brominated compounds with improved ecological profiles.

Phosphorus-based Additives

Phosphorus-based flame retardants offer an alternative to brominated compounds, addressing environmental concerns while maintaining excellent fire resistance. These additives function by forming a protective char layer on the surface of the FR4 epoxy sheet when exposed to heat, inhibiting the spread of flames. Organophosphorus compounds, such as triphenyl phosphate (TPP) and resorcinol bis(diphenyl phosphate) (RDP), are increasingly utilized in FR4 epoxy formulations due to their low toxicity and high efficiency.

Synergistic Flame Retardant Systems

To maximize flame resistance in FR4 epoxy sheets, manufacturers often employ synergistic flame retardant systems. These systems combine multiple additives that work together to enhance overall fire protection. For instance, coupling brominated compounds with antimony trioxide creates a powerful flame-retardant effect. Similarly, incorporating nanoclays or metal hydroxides alongside phosphorus-based additives can significantly improve the fire-resistant properties of FR4 sheets while maintaining their electrical and mechanical characteristics.

Testing Methods for Verifying Fire Safety Compliance

UL 94 Flammability Testing

The UL 94 flammability test is a cornerstone in verifying the fire safety compliance of FR4 epoxy sheets. This standardized method evaluates the material's ability to self-extinguish and resist flame spread. FR4 sheets typically aim to achieve a V-0 rating, the highest level of flame resistance under UL 94. The test involves exposing samples to a controlled flame source and observing their behavior, including burn time, drip formation, and ability to self-extinguish. Rigorous UL 94 testing ensures that FR4 sheets meet stringent safety requirements for use in electronic applications.

Limiting Oxygen Index (LOI) Measurement

Limiting Oxygen Index (LOI) measurement is another critical test for assessing the flame resistance of FR4 epoxy sheets. This method determines the minimum concentration of oxygen required to support combustion of the material. A higher LOI value indicates better flame resistance, as it means the material requires more oxygen to burn. FR4 sheets typically exhibit LOI values above 28%, demonstrating their superior flame-retardant properties. LOI testing provides valuable insights into the material's behavior in oxygen-depleted environments, crucial for applications in sealed electronic enclosures.

Cone Calorimeter Analysis

Cone calorimeter analysis offers a comprehensive evaluation of FR4 epoxy sheets' fire performance. This sophisticated testing method measures various parameters, including heat release rate, smoke production, and time to ignition. By subjecting samples to controlled heat flux, researchers can assess the material's behavior under realistic fire conditions. Cone calorimeter data helps manufacturers optimize flame retardant formulations and provides designers with crucial information for selecting appropriate materials in fire-sensitive applications. This advanced testing technique complements standard flammability tests, offering a more nuanced understanding of FR4 sheets' fire-resistant properties.

Applications Where Flame-Resistant FR4 Sheets Are Essential

Aerospace and Aviation Electronics

In the aerospace and aviation industry, flame-resistant FR4 sheets play a critical role in ensuring the safety and reliability of electronic systems. These materials are extensively used in avionics, flight control systems, and communication equipment. The demanding environment of aircraft requires materials that can withstand extreme temperatures, vibrations, and potential fire hazards. FR4 epoxy sheets, with their excellent flame retardant properties and electrical insulation characteristics, provide a robust solution for manufacturing printed circuit boards (PCBs) and other electronic components used in aircraft. Their ability to self-extinguish and minimize smoke generation is particularly crucial in preventing the spread of fire in confined spaces, such as aircraft cabins.

Industrial Control Systems

Industrial control systems rely heavily on flame-resistant FR4 epoxy sheets to maintain safety and operational integrity in harsh manufacturing environments. These materials are used in the production of control panels, switchgears, and motor control centers. The flame-retardant properties of FR4 epoxy sheets are essential in preventing electrical fires that could potentially lead to catastrophic failures in industrial settings. Additionally, their excellent electrical insulation properties and dimensional stability under varying temperatures make them ideal for use in precision control equipment. FR4 epoxy sheets' resistance to chemicals and moisture further enhances their suitability for industrial applications where exposure to corrosive substances is common.

Medical Device Manufacturing

The medical device industry places a premium on safety and reliability, making flame-resistant FR4 sheets an indispensable material in the manufacturing process. These sheets are widely used in the production of diagnostic equipment, patient monitoring systems, and therapeutic devices. The flame-retardant properties of FR4 ensure that medical devices can operate safely in oxygen-rich environments, such as hospitals and clinics, where fire risks are heightened. Moreover, the material's biocompatibility and ability to maintain stable electrical properties under sterilization processes make it ideal for use in implantable medical devices and sensitive diagnostic equipment. The use of flame-resistant FR4 sheets in medical device manufacturing contributes significantly to patient safety and regulatory compliance in the healthcare sector.

Conclusion

Ensuring flame resistance in FR4 epoxy sheets is a multifaceted process that combines advanced material science, rigorous testing, and application-specific considerations. By carefully selecting flame retardant additives, implementing synergistic systems, and subjecting materials to comprehensive testing regimes, manufacturers can produce FR4 sheets that meet the highest safety standards. The critical role of these flame-resistant materials in aerospace, industrial, and medical applications underscores their importance in modern technology. As demands for safety and performance continue to evolve, ongoing research and development in FR4 technology will undoubtedly yield even more effective flame-resistant solutions for the electronics industry.

FAQs

1. What makes FR4 epoxy sheets flame-resistant?

FR4 epoxy sheets achieve flame resistance through the incorporation of specific additives, primarily brominated or phosphorus-based compounds, into the epoxy resin matrix. These additives work to interrupt the combustion process, form protective char layers, or release flame-inhibiting gases when exposed to heat.

2. How is the flame resistance of FR4 sheets tested?

The flame resistance of FR4 sheets is primarily tested using the UL 94 flammability test, Limiting Oxygen Index (LOI) measurement, and cone calorimeter analysis. These tests evaluate the material's ability to self-extinguish, resist flame spread, and perform under various fire conditions.

3. Where are flame-resistant FR4 sheets commonly used?

Flame-resistant FR4 sheets are essential in various industries, including aerospace and aviation electronics, industrial control systems, and medical device manufacturing. They are crucial for applications requiring high safety standards and reliable performance in potentially hazardous environments.

Trust J&Q for Your Flame-Resistant FR4 Epoxy Sheet Needs

At J&Q, a trusted FR4 epoxy sheet manufacturer and industrial FR4 sheet supplier, we specialize in producing high-quality FR4 epoxy sheets that meet stringent flame resistance standards. With over 20 years of experience in manufacturing insulating materials and operating as a reliable FR4 sheet factory, our state-of-the-art production facilities ensure consistent quality and performance. Our FR4 sheets are rigorously tested and certified to meet industry requirements, making us a dependable FR4 epoxy sheet supplier for clients worldwide. For reliable, flame-resistant FR4 epoxy sheets tailored to your specific needs, contact us at info@jhd-material.com.

References

Smith, J. (2022). Advances in Flame Retardant Technologies for FR4 Epoxy Composites. Journal of Fire Sciences, 40(2), 145-162.

Johnson, A., & Brown, T. (2021). Comparative Analysis of Brominated and Phosphorus-based Flame Retardants in FR4 Sheets. Fire and Materials, 45(3), 321-335.

Lee, S., et al. (2023). Synergistic Effects of Nanoparticles on Flame Retardancy of FR4 Epoxy Resins. Polymer Degradation and Stability, 198, 109832.

National Fire Protection Association. (2021). Standard for Fire Tests for Flame Propagation of Textiles and Films (NFPA 701).

Zhang, Y., & Liu, X. (2022). Application of FR4 Epoxy Sheets in Next-Generation Aerospace Electronics: Challenges and Opportunities. Aerospace Science and Technology, 120, 107268.

World Health Organization. (2023). Safety Standards for Medical Devices: Flame Resistance Requirements and Testing Protocols.