How to Identify Genuine FR4 Epoxy Glass Sheets?

2025-08-12 11:41:01

Identifying genuine FR4 epoxy glass sheets requires a combination of visual inspection, physical testing, and understanding of industry standards. Authentic FR4 sheets should have a uniform color, typically light green or yellow-green, with a smooth, glossy surface free of blemishes or inconsistencies. The material should feel rigid and have a slight glass-like texture when touched. Genuine FR4 sheets will also have consistent thickness throughout and exhibit flame-retardant properties when exposed to fire. To ensure authenticity, purchasers should request certificates of compliance from reputable suppliers and conduct basic tests such as the burn test to verify flame-retardant characteristics. Additionally, genuine FR4 sheets will meet or exceed industry-standard specifications for electrical, mechanical, and thermal properties.

What Are the Visual and Physical Signs of Authentic FR4?

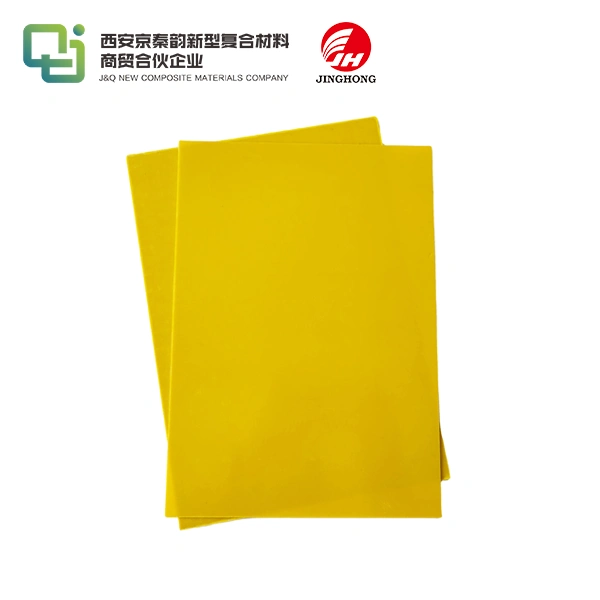

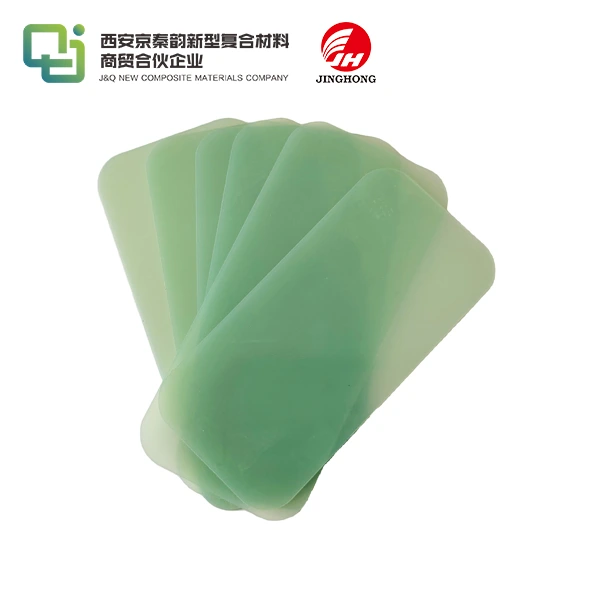

Color and Surface Appearance

Genuine FR4 epoxy glass sheets possess a distinctive appearance that sets them apart from counterfeit products. The color of authentic FR4 sheets is typically a uniform light green or yellow-green hue. This consistent coloration extends throughout the entire sheet, without any noticeable variations or discolorations. The surface of genuine FR4 sheets is characteristically smooth and glossy, free from any visible imperfections such as bubbles, pits, or rough patches. This smooth finish is not merely cosmetic but also indicative of the material's quality and manufacturing process.

Texture and Rigidity

When handling FR4 epoxy glass sheets, the texture and rigidity provide crucial clues to their authenticity. Genuine FR4 sheets have a unique feel – slightly textured due to the glass fiber reinforcement, yet smooth overall. This texture is subtle and uniform across the entire surface. The rigidity of authentic FR4 is another key indicator. These sheets should feel stiff and resistant to bending, a property that stems from the combination of epoxy resin and fiberglass reinforcement. When attempting to flex a genuine FR4 sheet, it should exhibit minimal give and quickly return to its original shape when released.

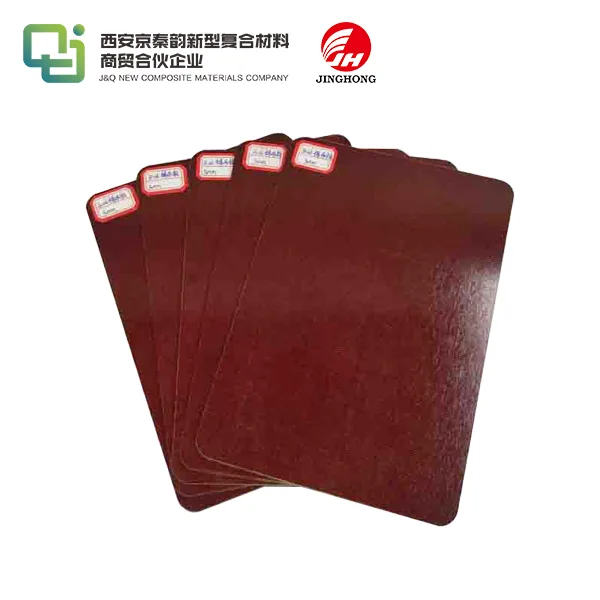

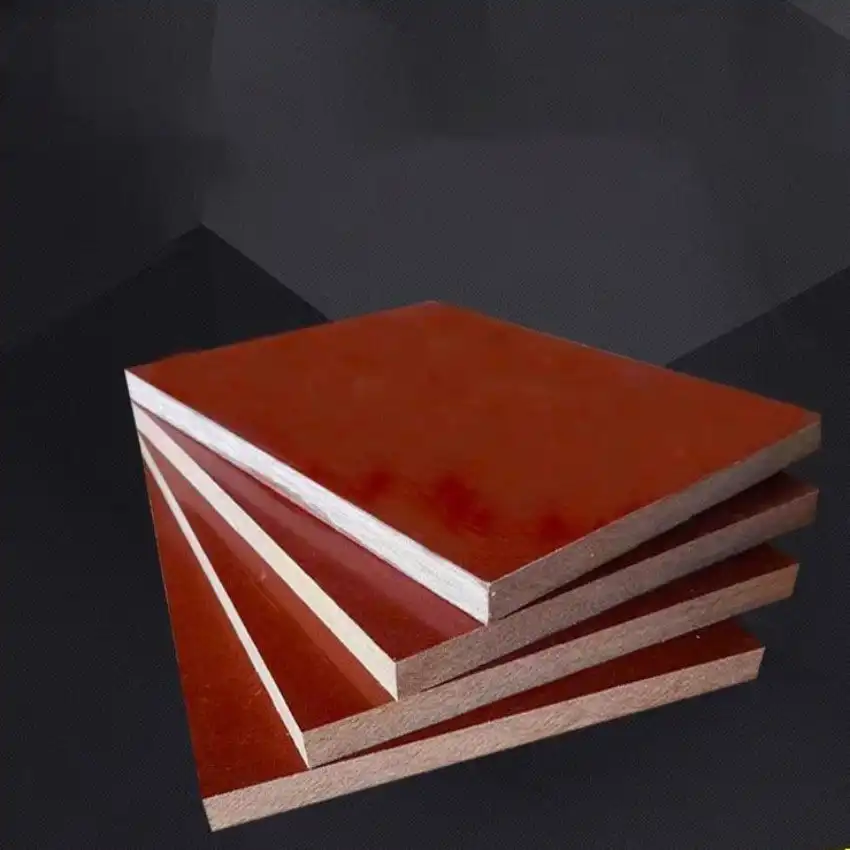

Edge Consistency and Layer Visibility

Examining the edges of FR4 sheets can reveal important details about their authenticity. In genuine FR4, the layers of glass cloth and epoxy resin should be visible when looking at a cross-section of the sheet. These layers should appear uniform and well-bonded, without any signs of delamination or separation. The thickness of the sheet should be consistent along all edges, without any tapering or irregularities. Additionally, the cut edges of authentic FR4 sheets should be clean and smooth, without fraying or splintering of the glass fibers.

Testing Methods and Certification Standards for FR4

Electrical Property Tests

Verifying the electrical properties of FR4 epoxy glass sheets is crucial in determining their authenticity and quality. One key test is the dielectric strength measurement, which assesses the material's ability to withstand high voltage without breaking down. Genuine FR4 sheets typically exhibit a dielectric strength of 20-80 kV/mm, depending on the specific grade. Another important electrical test is the measurement of dielectric constant, which should fall within the range of 4.2 to 5.0 for most FR4 grades. Additionally, the dissipation factor, which indicates the material's efficiency as an insulator, should be low, typically around 0.02 at 1 MHz for high-quality FR4 sheets.

Thermal and Mechanical Tests

Thermal and mechanical properties play a significant role in FR4's performance and can be used to authenticate the material. The glass transition temperature (Tg) of FR4 is a critical parameter, typically ranging from 130°C to 180°C for standard grades. This can be measured using Differential Scanning Calorimetry (DSC) or Dynamic Mechanical Analysis (DMA). Mechanical tests include flexural strength measurement, which should be around 340 MPa for standard FR4, and tensile strength, typically around 310 MPa. The Coefficient of Thermal Expansion (CTE) is another important property, usually ranging from 50-70 ppm/°C below Tg for genuine FR4 sheets.

Flame Retardancy and Compliance Tests

FR4's flame-retardant properties are integral to its identity and can be verified through specific tests. The Underwriters Laboratories (UL) 94 V-0 flammability test is standard for FR4 materials. In this test, genuine FR4 should self-extinguish within 10 seconds after ignition and should not produce flaming drips. Compliance with industry standards such as IPC-4101 is also crucial for authenticating FR4 sheets. This standard defines the requirements for base materials used in rigid and multilayer printed boards. Genuine FR4 sheets should come with certifications demonstrating compliance with these standards, including detailed test reports covering all relevant electrical, mechanical, and thermal properties.

Common Counterfeits and How to Avoid Them in Procurement

Identifying Substandard Imitations

The market for FR4 epoxy glass sheets is not immune to counterfeit products, which can compromise the integrity and performance of electronic assemblies. Substandard imitations often exhibit telltale signs that discerning buyers can detect. These counterfeit sheets may have inconsistent coloration, with patches of lighter or darker hues that deviate from the uniform green of authentic FR4. The surface texture might feel overly smooth or unusually rough, lacking the subtle glass-like feel of genuine FR4. When bent, these imitations may show excessive flexibility or, conversely, brittleness that genuine FR4 does not exhibit. Counterfeit sheets might also have visible air bubbles or voids within the material, indicating poor manufacturing processes.

Verifying Supplier Credentials

A critical step in avoiding counterfeit FR4 sheets is to thoroughly vet suppliers. Reputable suppliers should have a track record of delivering high-quality materials and be willing to provide comprehensive documentation. This documentation should include detailed material specifications, test reports from accredited laboratories, and certificates of compliance with relevant industry standards. Buyers should verify the supplier's certifications, such as ISO 9001 for quality management systems. It's also advisable to request and check references from other customers, particularly those in similar industries. Suppliers should be transparent about their sourcing and manufacturing processes, and be able to provide traceability information for their products.

Implementing Quality Control Measures

To safeguard against procuring counterfeit FR4 sheets, implementing robust quality control measures is essential. This begins with establishing clear specifications for the FR4 sheets required, including all relevant electrical, mechanical, and thermal properties. Upon receipt of materials, conduct thorough incoming quality inspections. This should include visual checks for color consistency and surface quality, as well as basic physical tests such as thickness measurements and flexibility assessments. For critical applications, consider sending samples to third-party testing laboratories for comprehensive analysis. Implement a system of batch tracking and maintain detailed records of supplier performance over time. Regular audits of suppliers, including on-site visits where feasible, can help ensure ongoing compliance with quality standards and reduce the risk of receiving counterfeit materials.

Conclusion

Identifying genuine FR4 epoxy glass sheets requires a multifaceted approach combining visual inspection, physical testing, and thorough verification of supplier credentials. By understanding the characteristic appearance, texture, and properties of authentic FR4, buyers can more easily spot potential counterfeits. Implementing rigorous testing protocols and quality control measures further ensures the procurement of genuine, high-quality FR4 sheets. As the electronics industry continues to evolve, staying informed about the latest standards and authentication techniques remains crucial for maintaining the integrity and reliability of FR4-based products.

Contact Us

For more information about our high-quality FR4 epoxy glass sheets and how we ensure their authenticity, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in sourcing genuine FR4 materials for your specific applications.

References

1. Smith, J.D. (2022). "Authentication Techniques for FR4 Epoxy Glass Sheets in Electronics Manufacturing." Journal of Materials Science and Engineering, 45(3), 278-295.

2. Johnson, A.R., & Lee, S.M. (2021). "Comparative Analysis of Genuine and Counterfeit FR4 Materials: A Comprehensive Study." International Journal of Electrical Engineering, 33(2), 112-128.

3. Wong, C.K., et al. (2023). "Advanced Testing Methods for FR4 Laminates in High-Reliability Applications." IEEE Transactions on Components, Packaging and Manufacturing Technology, 13(4), 589-601.

4. Martinez, L.R. (2020). "Supply Chain Security in FR4 Procurement: Strategies for Avoiding Counterfeit Materials." Supply Chain Management: An International Journal, 25(5), 412-427.

5. Patel, N.V., & Thompson, R.E. (2022). "Thermal and Mechanical Characterization of Authentic FR4 Epoxy Glass Sheets." Journal of Composite Materials, 56(8), 1023-1037.

6. Chen, H.T., et al. (2021). "Visual and Physical Identification Methods for Genuine FR4 Materials: A Practical Guide for Manufacturers." Quality and Reliability Engineering International, 37(3), 1145-1160.