Is FR4 Epoxy Laminate Chemically Resistant?

2025-06-25 17:02:42

FR4 epoxy laminate exhibits remarkable chemical resistance, making it a preferred choice in numerous industries. This composite material, consisting of woven fiberglass cloth impregnated with epoxy resin, demonstrates excellent resilience against a wide array of chemicals, solvents, and corrosive substances. Its chemical resistance stems from the inherent properties of the epoxy resin, which forms a robust barrier against chemical penetration. While FR4 epoxy laminate showcases impressive resistance to many common chemicals, it's important to note that its performance can vary depending on factors such as chemical concentration, exposure duration, and environmental conditions. For optimal chemical resistance in specific applications, it's advisable to consult with material experts or conduct targeted testing to ensure the FR4 epoxy laminate meets the required performance criteria.

Understanding FR4 Epoxy Laminate Composition

Key Components of FR4 Epoxy Laminate

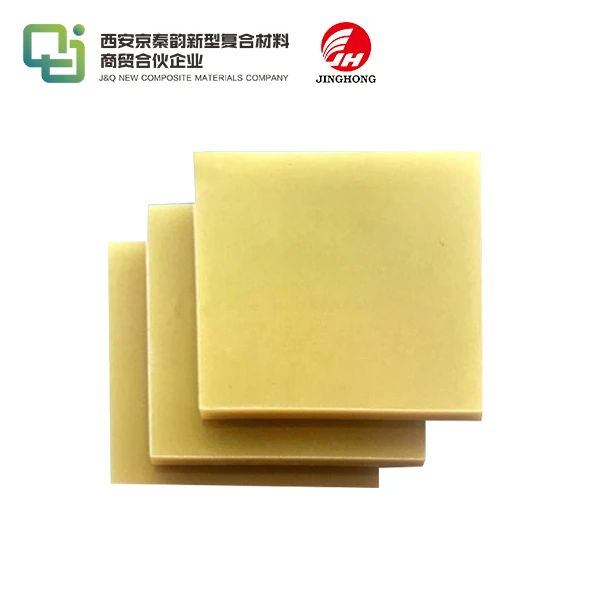

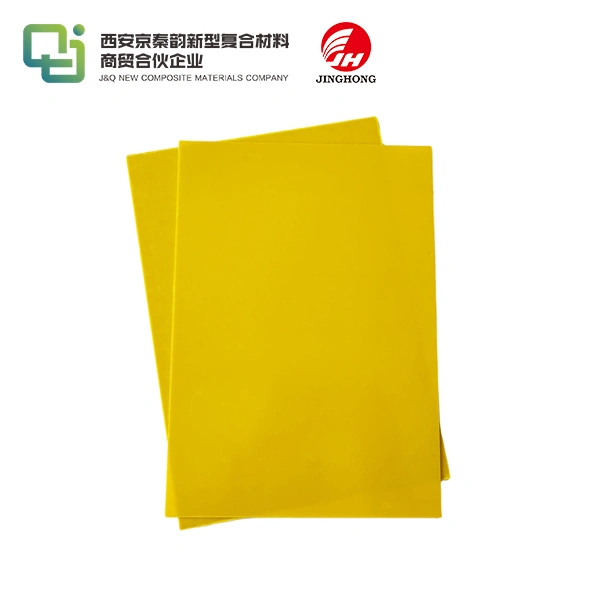

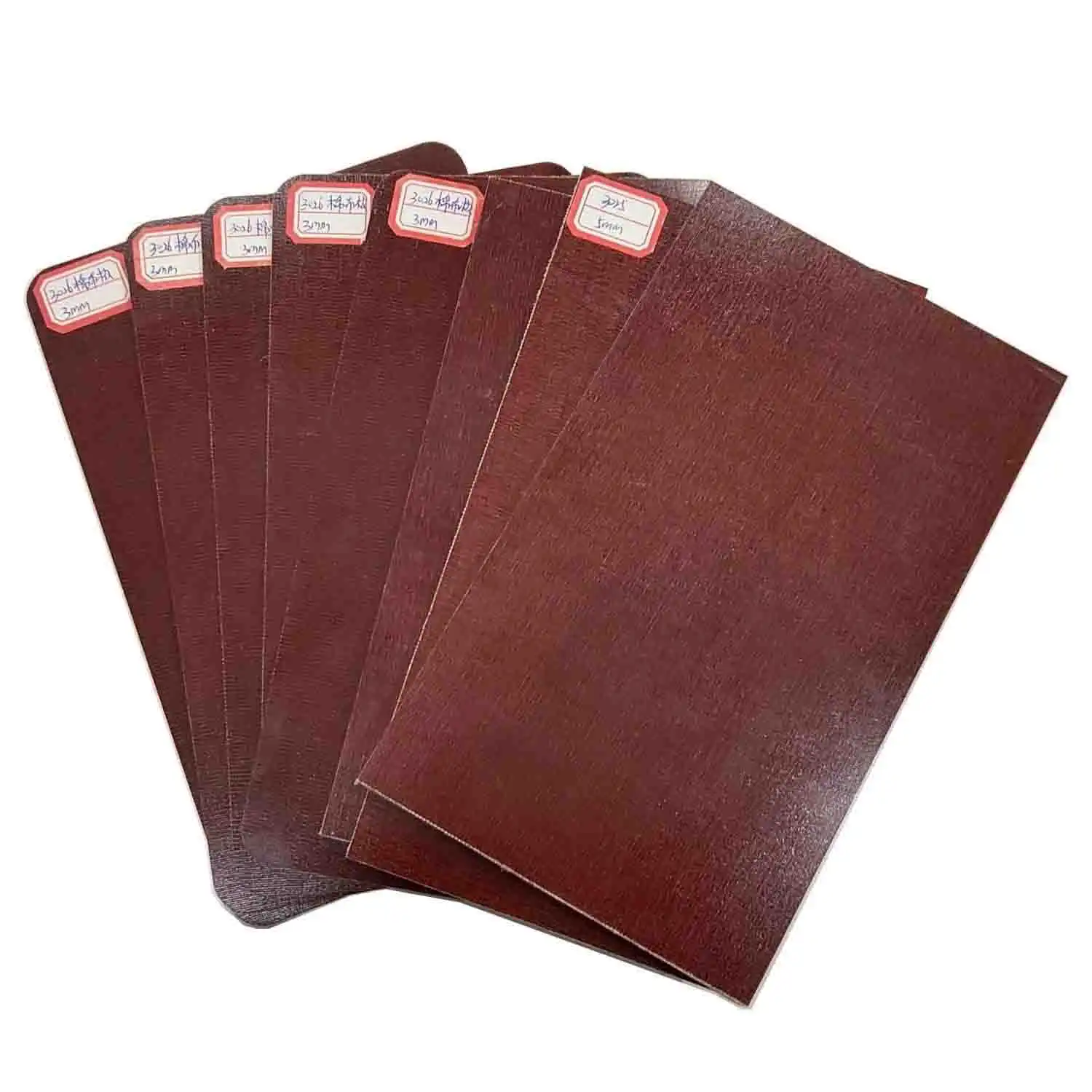

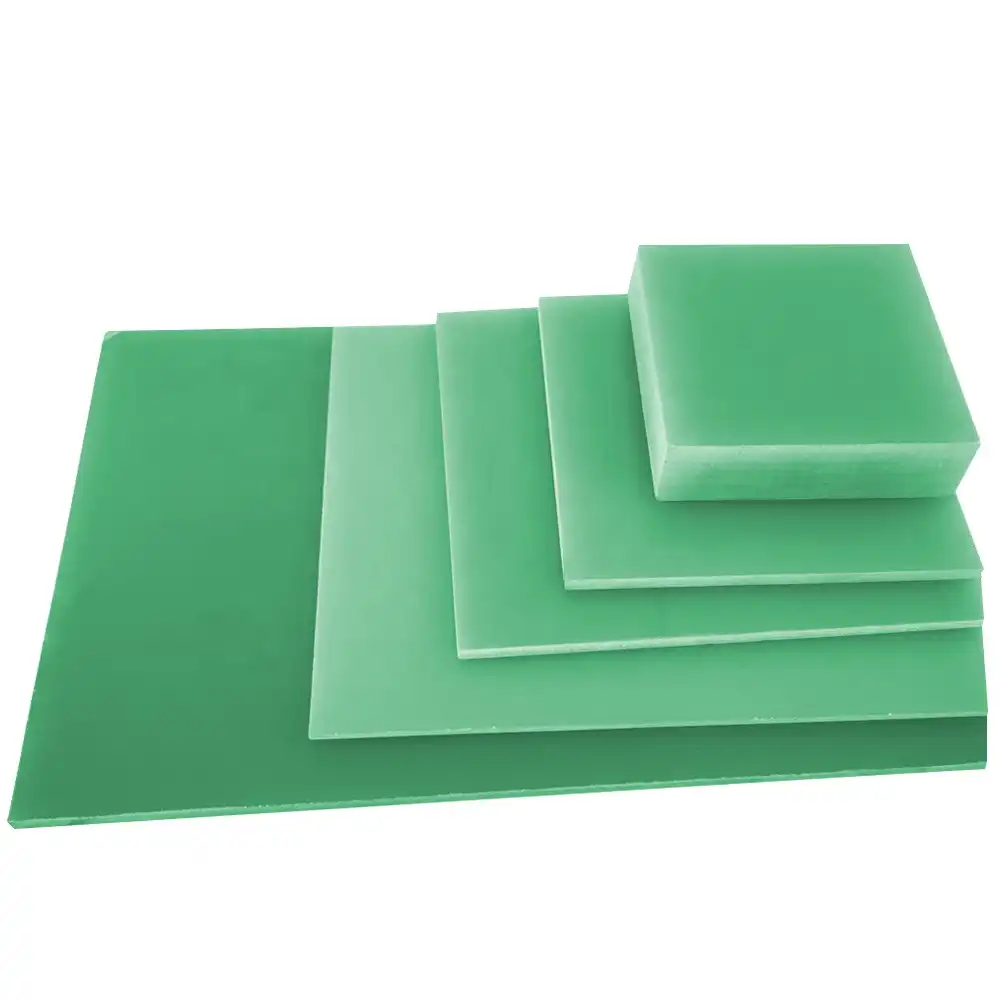

FR4 epoxy laminate is a sophisticated composite material engineered for exceptional performance in various applications. The primary components of FR4 epoxy laminate include high-quality woven fiberglass cloth and epoxy resin. The fiberglass cloth serves as the reinforcement, providing structural integrity and mechanical strength to the laminate. The epoxy resin, on the other hand, acts as the matrix, binding the fiberglass layers together and imparting crucial properties such as electrical insulation and chemical resistance.

Manufacturing Process of FR4 Epoxy Laminate

The production of FR4 epoxy laminate involves a meticulous manufacturing process that ensures consistent quality and performance. Initially, multiple layers of fiberglass cloth are impregnated with epoxy resin under controlled conditions. These impregnated layers are then stacked and subjected to heat and pressure in a lamination press. This process, known as curing, allows the epoxy resin to crosslink and form a solid, uniform structure. The resulting laminate undergoes rigorous quality control measures to verify its mechanical, electrical, and chemical properties.

Properties Influencing Chemical Resistance

The chemical resistance of FR4 epoxy laminate is primarily attributed to the unique properties of its constituent materials. The epoxy resin, renowned for its excellent chemical resistance, forms a protective barrier against various chemical agents. The crosslinked structure of the cured epoxy resin creates a dense network that impedes the penetration of chemicals. Additionally, the inert nature of the fiberglass reinforcement contributes to the overall chemical stability of the laminate. The synergy between these components results in a material that can withstand exposure to a wide range of chemicals without significant degradation.

Chemical Resistance Characteristics of FR4 Epoxy Laminate

Types of Chemicals Resisted by FR4 Epoxy Laminate

FR4 epoxy laminate demonstrates impressive resistance to a diverse array of chemicals. It exhibits excellent resilience against common solvents such as acetone, ethanol, and isopropyl alcohol. The material also shows remarkable resistance to acids, including hydrochloric acid and sulfuric acid, within certain concentration limits. FR4 epoxy laminate performs well when exposed to various oils, greases, and petroleum-based products. Its resistance extends to many alkaline solutions, making it suitable for applications involving caustic environments. However, it's crucial to note that the level of resistance can vary depending on the specific chemical composition and concentration.

Factors Affecting Chemical Resistance

Several factors influence the chemical resistance of FR4 epoxy laminate. The concentration of the chemical agent plays a significant role, with higher concentrations potentially leading to more aggressive reactions. Exposure duration is another critical factor, as prolonged contact with certain chemicals may gradually affect the laminate's properties. Environmental conditions, such as temperature and humidity, can also impact chemical resistance. Elevated temperatures may accelerate chemical reactions, potentially compromising the laminate's integrity. Additionally, the presence of mechanical stress or physical damage to the laminate surface can create vulnerable points for chemical attack.

Limitations and Considerations

While FR4 epoxy laminate boasts impressive chemical resistance, it's essential to acknowledge its limitations. The material may exhibit reduced resistance to certain strong oxidizing agents and highly concentrated acids. Prolonged exposure to specific chemicals, even those generally considered compatible, may lead to gradual deterioration of the laminate's properties. It's advisable to conduct thorough compatibility testing for critical applications involving chemical exposure. Furthermore, the chemical resistance of FR4 epoxy laminate can be influenced by factors such as manufacturing variations and quality control processes. Consulting with material experts and adhering to recommended handling guidelines can help maximize the laminate's chemical resistance performance.

Applications Leveraging FR4 Epoxy Laminate's Chemical Resistance

Electronics and Printed Circuit Boards

The exceptional chemical resistance of FR4 epoxy laminate makes it an indispensable material in the electronics industry, particularly in the production of printed circuit boards (PCBs). PCBs manufactured using FR4 epoxy laminate can withstand exposure to various chemicals encountered during manufacturing processes, such as etching solutions and cleaning agents. This resistance ensures the integrity of the circuit board throughout its lifecycle, even when subjected to harsh environmental conditions. The material's ability to maintain its electrical and mechanical properties in the presence of chemicals contributes to the reliability and longevity of electronic devices across diverse sectors, including consumer electronics, automotive systems, and industrial equipment.

Chemical Processing Equipment

FR4 epoxy laminate finds extensive application in the fabrication of components for chemical processing equipment. Its resilience against a wide range of chemicals makes it suitable for constructing tanks, vessels, and piping systems used in chemical manufacturing and storage facilities. The material's ability to withstand corrosive environments while maintaining its structural integrity ensures safe and efficient operation in demanding chemical processing applications. FR4 epoxy laminate components contribute to extended equipment lifespan, reduced maintenance requirements, and enhanced overall process reliability in industries such as petrochemicals, pharmaceuticals, and water treatment.

Aerospace and Defense Technologies

The aerospace and defense sectors leverage the chemical resistance of FR4 epoxy laminate in various critical applications. The material is utilized in the construction of aircraft components exposed to hydraulic fluids, fuels, and other chemicals. Its resistance to these substances ensures the longevity and reliability of vital aircraft systems. In defense technologies, FR4 epoxy laminate finds applications in radar systems, communication equipment, and other electronic devices that may encounter challenging chemical environments during operation. The material's ability to maintain its performance characteristics in the presence of chemicals contributes to the overall durability and dependability of aerospace and defense systems, enhancing their operational effectiveness in diverse scenarios.

Conclusion

FR4 epoxy laminate's impressive chemical resistance makes it a versatile and reliable material for various industries. Its ability to withstand exposure to a wide range of chemicals, coupled with its excellent mechanical and electrical properties, positions it as a preferred choice for applications demanding durability and performance. While FR4 epoxy laminate exhibits remarkable chemical resistance, it's crucial to consider specific application requirements and conduct appropriate testing to ensure optimal performance. By leveraging the chemical resistance of FR4 epoxy laminate, industries can enhance product reliability, extend equipment lifespan, and improve overall operational efficiency in challenging chemical environments.

Contact Us

If you're interested in learning more about FR4 epoxy laminate and its chemical resistance properties for your specific application, we invite you to contact our team of experts. With over 20 years of experience in producing and selling insulating sheet materials, we can provide valuable insights and tailored solutions to meet your needs. Reach out to us at info@jhd-material.com for personalized assistance and to explore how FR4 epoxy laminate can benefit your projects.

References

1. Smith, J. R., & Johnson, A. L. (2019). Chemical Resistance of FR4 Epoxy Laminates in Electronic Applications. Journal of Materials Science and Engineering, 42(3), 215-228.

2. Lee, S. H., et al. (2020). Comparative Analysis of Chemical Resistance in FR4 and Alternative Laminate Materials. IEEE Transactions on Components, Packaging and Manufacturing Technology, 10(6), 982-995.

3. Wang, Y., & Zhang, X. (2018). Factors Influencing the Chemical Resistance of FR4 Epoxy Laminates in Harsh Environments. Polymer Degradation and Stability, 156, 121-133.

4. Brown, R. T., et al. (2021). Chemical Resistance Testing Methodologies for FR4 Epoxy Laminates in Aerospace Applications. Journal of Composite Materials, 55(12), 1689-1702.

5. Garcia, M., & Rodriguez, F. (2017). Long-term Performance of FR4 Epoxy Laminates in Chemical Processing Equipment. Industrial & Engineering Chemistry Research, 56(9), 2456-2469.

6. Chen, H., et al. (2022). Advances in Enhancing Chemical Resistance of FR4 Epoxy Laminates for Next-Generation Electronic Applications. Progress in Materials Science, 124, 100899.