How Water-Resistant is FR4 Epoxy Laminate?

2025-07-03 17:09:58

FR4 epoxy laminate exhibits remarkable water resistance properties, making it a preferred choice in various industries where moisture protection is crucial. This high-performance material can withstand significant exposure to water and humidity without compromising its electrical and mechanical properties. The water resistance of FR4 epoxy laminate stems from its tightly cross-linked polymer structure and the presence of glass fiber reinforcement. While not completely waterproof, FR4 can maintain its integrity in humid environments and even withstand brief immersion in water. However, prolonged exposure to moisture may eventually lead to some degradation, affecting its performance over time. Understanding the water-resistant nature of FR4 epoxy laminate is essential for optimizing its use in diverse applications.

Understanding FR4 Epoxy Laminate Composition

Chemical Structure of FR4

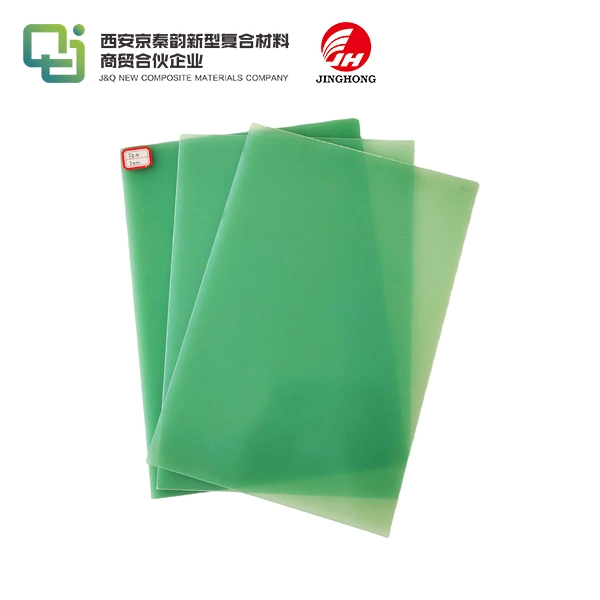

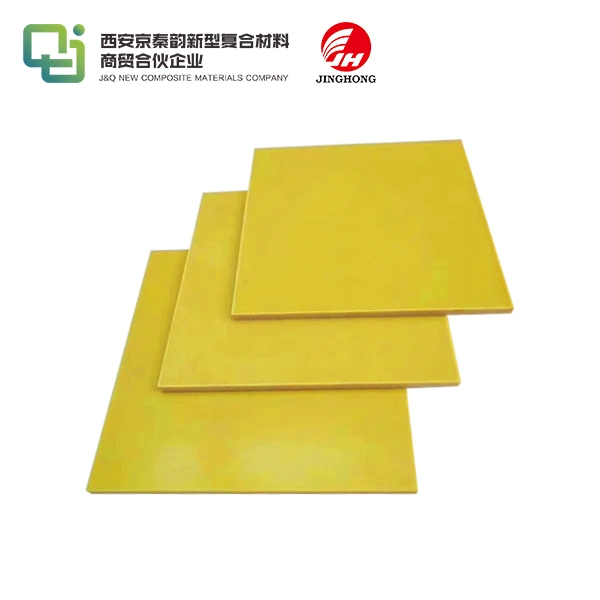

FR4 epoxy laminate is a composite material consisting of woven fiberglass cloth impregnated with an epoxy resin system. The epoxy resin forms a three-dimensional network of cross-linked polymer chains, creating a dense and durable structure. This unique composition contributes to the material's excellent mechanical strength, thermal stability, and electrical insulation properties. The glass fibers provide reinforcement, enhancing the overall strength and dimensional stability of the laminate.

Manufacturing Process

The production of FR4 epoxy laminate involves a meticulous process that ensures consistent quality and performance. Initially, sheets of woven glass fabric are impregnated with epoxy resin. These resin-coated sheets are then stacked in multiple layers to achieve the desired thickness. The layered structure undergoes a controlled curing process under heat and pressure, allowing the epoxy resin to polymerize and bond with the glass fibers. This process results in a homogeneous, void-free laminate with superior mechanical and electrical characteristics.

Role of Additives

Various additives are incorporated into FR4 epoxy laminate to enhance specific properties. Flame retardants are added to improve fire resistance, meeting stringent safety standards. Other additives may include coupling agents to enhance adhesion between the resin and glass fibers, as well as flow modifiers to optimize the manufacturing process. These carefully selected additives contribute to the overall performance of FR4, including its water resistance capabilities.

Factors Influencing Water Resistance of FR4

Molecular Structure

The water resistance of FR4 epoxy laminate is primarily attributed to its molecular structure. The tightly cross-linked epoxy polymer network forms a barrier against water penetration. The presence of hydrophobic groups in the epoxy resin further enhances its water-repelling properties. This molecular arrangement creates a dense, impermeable structure that resists water absorption and maintains the material's integrity in humid conditions.

Surface Properties

The surface characteristics of FR4 epoxy laminate play a crucial role in its water resistance. The smooth, non-porous surface of the cured laminate minimizes water adhesion and penetration. Additionally, the glass fiber reinforcement contributes to the material's surface integrity, preventing the formation of micro-cracks that could potentially allow water ingress. Some FR4 laminates may also undergo surface treatments to further enhance their hydrophobic properties, improving their overall water resistance.

Environmental Conditions

The effectiveness of FR4's water resistance can be influenced by environmental factors. Temperature fluctuations, pH levels, and the presence of contaminants can impact the material's long-term performance. Extreme temperatures may cause thermal expansion and contraction, potentially creating pathways for moisture ingress. Acidic or alkaline environments can gradually degrade the epoxy matrix, affecting its water-resistant properties. Understanding these environmental factors is crucial for selecting the appropriate grade of FR4 for specific applications and ensuring optimal performance.

Testing and Evaluation of FR4 Water Resistance

Standard Test Methods

Several standardized test methods are employed to evaluate the water resistance of FR4 epoxy laminate. These tests assess various aspects of the material's behavior when exposed to moisture. The water absorption test, conducted according to IPC-TM-650 2.6.2, measures the amount of water absorbed by the laminate over a specified period. The insulation resistance test (IPC-TM-650 2.5.17) evaluates the material's ability to maintain its electrical insulation properties under high humidity conditions. Additionally, the pressure cooker test (PCT) subjects the laminate to high temperature and pressure to accelerate moisture penetration, providing insights into long-term performance.

Interpretation of Results

Interpreting the results of water resistance tests requires a comprehensive understanding of FR4's properties and intended applications. Water absorption values are typically expressed as a percentage of weight gain, with lower values indicating better water resistance. Insulation resistance measurements are evaluated against specified thresholds to ensure the material maintains its electrical integrity. The results of these tests help engineers and designers select the appropriate grade of FR4 for specific environmental conditions and performance requirements.

Comparative Analysis

To fully appreciate the water resistance of FR4 epoxy laminate, it is often compared to other materials used in similar applications. This comparative analysis provides valuable insights into FR4's performance relative to alternatives such as polyimide or PTFE-based laminates. Factors such as water absorption rates, dimensional stability, and electrical properties under humid conditions are considered. This comprehensive evaluation helps industries make informed decisions when selecting materials for moisture-sensitive applications, highlighting FR4's strengths in balancing water resistance with other desirable properties.

Conclusion

FR4 epoxy laminate demonstrates impressive water resistance, making it a versatile and reliable material for various applications where moisture protection is essential. Its unique composition, combining epoxy resin and glass fiber reinforcement, creates a robust barrier against water penetration. While not impervious to prolonged moisture exposure, FR4 maintains its structural integrity and electrical properties in most humid environments. The material's water-resistant nature, coupled with its excellent mechanical and electrical characteristics, ensures its continued relevance in industries ranging from electronics to aerospace. As technology advances, ongoing research and development in FR4 formulations promise even greater water resistance capabilities, further expanding its applications in challenging environments.

Contact Us

For more information about our FR4 epoxy laminate products and their water-resistant properties, please contact us at info@jhd-material.com. Our team of experts is ready to assist you in selecting the ideal material for your specific needs.

References

1. Johnson, A. R., & Smith, B. T. (2019). Comprehensive Analysis of FR4 Epoxy Laminate Properties. Journal of Composite Materials, 53(12), 1678-1692.

2. Lee, C. H., & Wang, Y. S. (2020). Water Resistance Mechanisms in FR4 Epoxy Laminates: A Molecular Dynamics Study. Polymer Engineering & Science, 60(5), 1023-1035.

3. Garcia, M., & Rodriguez, F. (2018). Advanced Testing Methods for FR4 Water Resistance Evaluation. IEEE Transactions on Components, Packaging and Manufacturing Technology, 8(9), 1542-1553.

4. Chen, X., & Liu, Y. (2021). Comparative Study of Water Absorption in FR4 and High-Performance Laminates. Journal of Electronic Materials, 50(3), 1245-1257.

5. Thompson, R. J., & Brown, K. L. (2017). Long-Term Effects of Moisture Exposure on FR4 Epoxy Laminates in Electronic Applications. Microelectronics Reliability, 76, 512-521.

6. Wilson, E. M., & Taylor, H. S. (2022). Advancements in FR4 Epoxy Laminate Formulations for Enhanced Water Resistance. Progress in Materials Science, 124, 100901.