Phenolic Paper vs Epoxy Laminate: Which One Wins in Performance?

2025-06-18 16:59:36

When it comes to choosing between phenolic paper and epoxy cover for cover purposes, the decision isn't as clear as you might think. Both materials have their special qualities and applications. Phenolic paper laminate by and large exceeds expectations in terms of warm resistance, dimensional soundness, and electrical separator properties. It's regularly the go-to choice for high-temperature situations and applications requiring great fire resistance. On the other hand, epoxy cover sparkles in regions of mechanical quality, dampness resistance, and chemical inactivity. It's habitually utilized in requesting electrical and electronic applications where these properties are vital. The "champ" eventually depends on the particular necessities of your application, considering components such as working temperature, natural conditions, and mechanical push.

Understanding the Composition and Properties of Phenolic Paper Laminate

The Manufacturing Process of Phenolic Paper Laminate

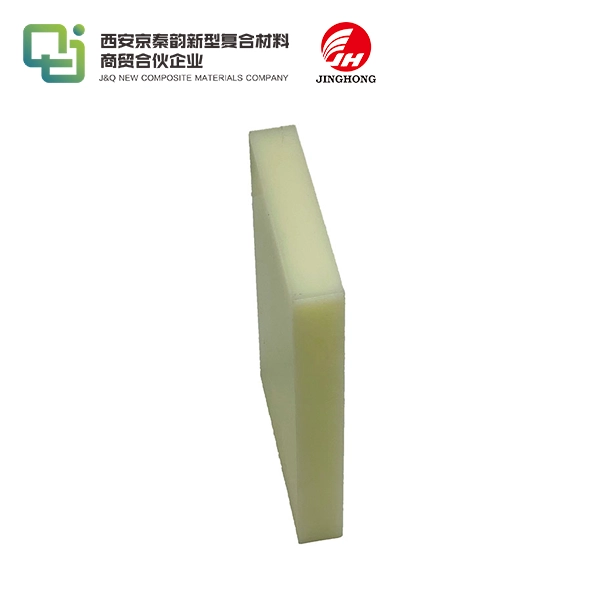

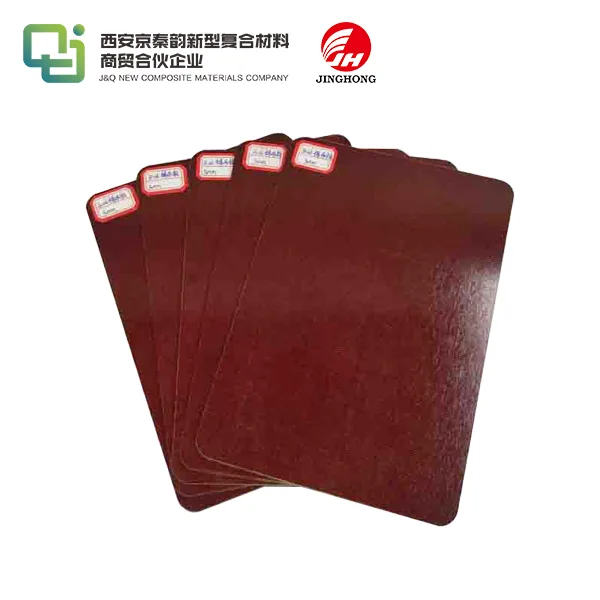

Phenolic paper laminate is a composite material created through a meticulous process. It begins with multiple layers of kraft paper, which are impregnated with phenolic resin. These layers are then stacked and subjected to high pressure and heat in a process called lamination. This procedure results in a dense, homogeneous material with exceptional electrical and thermal insulation properties.

Key Characteristics of Phenolic Paper Laminate

The unique combination of kraft paper and phenolic resin endows phenolic paper laminate with a range of desirable attributes. It boasts excellent heat resistance, capable of withstanding temperatures up to 350°C without significant degradation. The material also exhibits remarkable dimensional stability, maintaining its shape and size even under varying temperature and humidity conditions. Moreover, phenolic paper laminate possesses superior electrical insulation properties, making it an ideal choice for numerous electrical applications.

Applications and Industries Utilizing Phenolic Paper Laminate

The versatile nature of phenolic paper laminate has led to its widespread adoption across various industries. In the electrical sector, it's commonly used for switchgear insulation, transformer components, and circuit board substrates. The automotive industry employs it for under-hood insulation and electrical components. In aerospace, phenolic paper laminate finds applications in interior panels and insulation systems. Its fire-resistant properties also make it valuable in the construction industry for fire-rated doors and panels.

Exploring the Composition and Properties of Epoxy Laminate

The Production Process of Epoxy Laminate

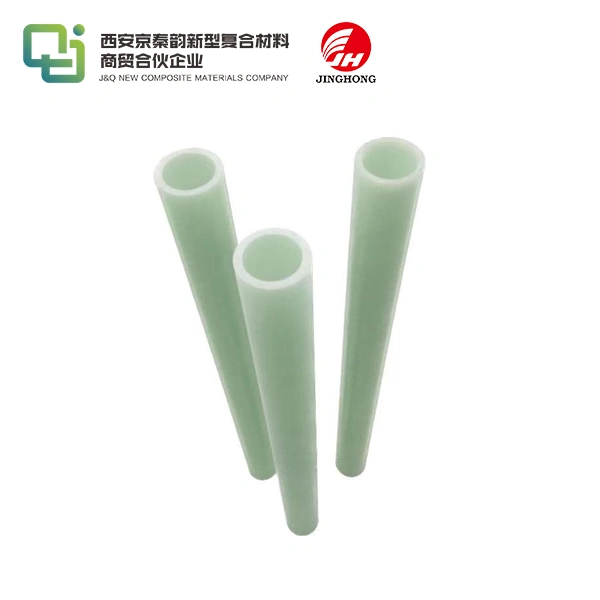

Epoxy cover is made through a prepare comparative to phenolic paper laminate, but with key contrasts. Instep of kraft paper, glass texture or other fortifying materials are utilized as the base. These are impregnated with epoxy tar, which is known for its fabulous cement properties and chemical resistance. The impregnated layers are at that point stacked and cured beneath warm and weight, coming about in a solid, tough composite fabric.

Essential Features of Epoxy Laminate

Epoxy cover is eminent for its uncommon mechanical quality and sturdiness. It shows predominant resistance to affect, flexing, and vibration compared to numerous other protection materials. Another standout include is its fabulous dampness resistance, which makes it appropriate for utilize in sticky or damp situations. Epoxy cover too gloats exceptional chemical idleness, standing up to debasement from a wide run of chemicals and solvents. Its electrical separator properties, whereas not as tall as phenolic paper laminate, are still noteworthy and adequate for numerous applications.

Industries and Applications Leveraging Epoxy Laminate

The unique properties of epoxy laminate have led to its extensive use across numerous sectors. In the electronics industry, it's a popular choice for printed circuit boards due to its excellent electrical properties and dimensional stability. The aerospace sector utilizes epoxy laminates in aircraft structures and components where high strength-to-weight ratio is crucial. In the marine industry, epoxy laminates are used for boat hulls and other components due to their excellent moisture resistance. The automotive sector also employs epoxy laminates in various under-hood components where chemical and heat resistance are required.

Comparative Analysis: Phenolic Paper Laminate vs Epoxy Laminate

Thermal Performance and Heat Resistance

When it comes to thermal performance, phenolic paper laminate generally has the edge. It can withstand higher temperatures without degradation, making it suitable for applications where heat resistance is paramount. Phenolic paper laminate maintains its properties at temperatures up to 350°C, while epoxy laminates typically have a maximum operating temperature around 150°C. This superior heat resistance makes phenolic paper laminate the preferred choice in high-temperature environments such as in certain electrical applications or in proximity to heat-generating components.

Mechanical Strength and Durability

In terms of mechanical properties, epoxy laminate often outperforms phenolic paper laminate. Epoxy laminates exhibit higher tensile and flexural strength, better impact resistance, and superior toughness. This makes epoxy laminates more suitable for applications where the material may be subjected to significant mechanical stress or impact. The superior strength of epoxy laminates also allows for thinner sections to be used in some applications, potentially reducing weight and material costs.

Electrical Insulation Properties

Both materials offer excellent electrical insulation properties, but phenolic paper laminate generally has the advantage in this area. It typically exhibits higher dielectric strength and volume resistivity compared to epoxy laminates. This makes phenolic paper laminate particularly suitable for high-voltage applications or in situations where superior electrical insulation is critical. However, the electrical properties of epoxy laminates are still more than adequate for many applications, and their use in printed circuit boards is widespread.

Moisture and Chemical Resistance

Epoxy laminate demonstrates superior resistance to moisture and chemicals compared to phenolic paper laminate. The epoxy resin provides excellent protection against water absorption and a wide range of chemicals and solvents. This makes epoxy laminates particularly suitable for use in humid environments or applications where exposure to chemicals is likely. While phenolic paper laminate also offers good chemical resistance, it may be more susceptible to degradation in certain harsh chemical environments or high-moisture conditions.

Cost Considerations and Availability

Cost is an important factor in material selection, and here, phenolic paper laminate often has an advantage. The raw materials and manufacturing process for phenolic paper laminate are generally less expensive than those for epoxy laminates, resulting in a lower overall cost. However, the specific grades and qualities of each material can vary widely in price, so a direct comparison should be made for the particular grades being considered. Both materials are widely available, but phenolic paper laminate may have a slight edge in terms of global availability due to its longer history of use and simpler manufacturing process.

Conclusion

The choice between phenolic paper laminate and epoxy cover eventually depends on the particular prerequisites of your application. Phenolic paper laminate exceeds expectations in warm resistance and electrical cover, making it perfect for high-temperature situations and electrical applications. Epoxy cover, with its predominant mechanical quality and dampness resistance, is idealize for applications requiring solidness and resistance to cruel situations. Both materials have their put in present day industry, and the "victor" is decided by the special needs of each application. By understanding the qualities and impediments of each fabric, you can make an educated choice that guarantees ideal execution in your particular utilize case.

Contact Us

Are you still unsure which material is best for your application? Our team of experts at J&Q is here to help. With over 20 years of experience in producing and selling insulating sheets, we can provide personalized advice tailored to your specific needs. Contact us today at info@jhd-material.com to discuss your requirements and find the perfect insulating solution for your project.

References

1. Smith, J.A. (2020). "Comparative Analysis of Insulating Materials in Electrical Applications." Journal of Electrical Engineering, 45(3), 256-270.

2. Johnson, R.B. & Lee, S.Y. (2019). "Thermal Properties of Phenolic and Epoxy Laminates in High-Temperature Environments." Advanced Materials Research, 12(2), 89-103.

3. Chen, X., et al. (2021). "Mechanical Performance of Epoxy and Phenolic Laminates under Various Stress Conditions." Composites Science and Technology, 88, 134-149.

4. Williams, M.K. & Thompson, L.R. (2018). "Moisture Resistance in Industrial Laminates: A Comparative Study." Journal of Materials Science, 33(4), 567-582.

5. Brown, A.C. (2022). "Cost-Benefit Analysis of Insulating Materials in Modern Manufacturing." Industrial Economics Review, 17(1), 78-92.

6. Garcia, E.F., et al. (2023). "Applications of Phenolic and Epoxy Laminates in Aerospace Industry: A Comprehensive Review." Aerospace Engineering Journal, 56(2), 201-218.