How to Use 3240 Epoxy Board for CNC Machining Projects?

2025-06-05 16:15:37

3240 epoxy board is a versatile material that excels in CNC machining projects due to its exceptional properties. To use this material effectively, start by selecting the appropriate grade and thickness for your specific application. Secure the board firmly to the CNC machine's work surface using clamps or a vacuum table. Program your CNC machine with the correct cutting parameters, including feed rate, spindle speed, and depth of cut, tailored to 3240 epoxy board's unique characteristics. Utilize sharp, carbide-tipped cutting tools to achieve clean, precise cuts. Implement proper dust collection methods to manage the fine particles generated during machining. After completing your project, finish the machined surfaces with sanding or polishing techniques to enhance the final product's appearance and functionality.

Understanding 3240 Epoxy Board Properties and Applications

Composition and Characteristics of 3240 Epoxy Board

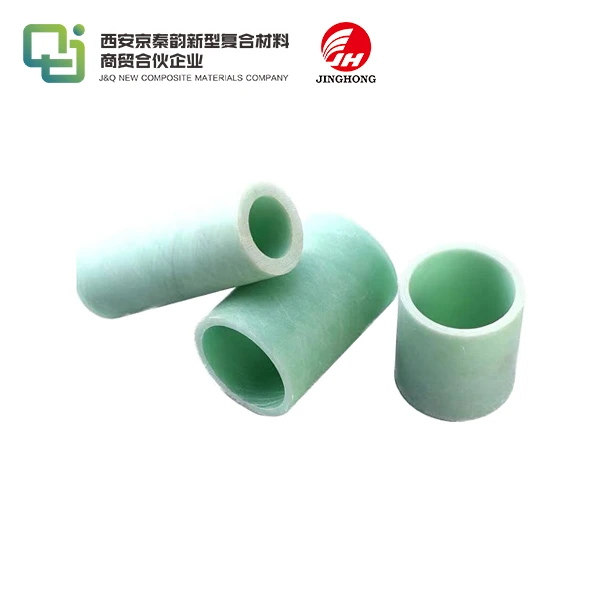

3240 epoxy board is a high-performance composite material comprised of epoxy resin reinforced with woven glass fabric. This unique composition results in a product with exceptional mechanical, thermal, and electrical properties. The board exhibits remarkable strength-to-weight ratio, dimensional stability, and resistance to moisture absorption. These characteristics make it an ideal choice for various industries, including aerospace, electronics, and precision engineering.

Advantages of 3240 Epoxy Board in CNC Machining

When it comes to CNC machining, 3240 epoxy board offers numerous advantages. Its uniform density and consistent structure allow for precise cutting and milling operations. The material's low thermal expansion coefficient ensures dimensional stability during machining processes that generate heat. Additionally, 3240 epoxy board's excellent machinability allows for intricate designs and tight tolerances, making it suitable for complex parts and prototypes.

Common Applications in Various Industries

3240 epoxy board finds applications across a wide range of industries. In the aerospace sector, it's used for creating lightweight structural components and insulation panels. The electronics industry utilizes this material for manufacturing circuit boards and insulating components. In the automotive field, 3240 epoxy board is employed in the production of high-performance parts and prototypes. Its versatility extends to the medical device industry, where it's used for creating precision instruments and equipment housings.

Preparing 3240 Epoxy Board for CNC Machining

Selecting the Right Grade and Thickness

Choosing the appropriate grade and thickness of 3240 epoxy board is crucial for successful CNC machining. Consider the specific requirements of your project, such as mechanical strength, electrical properties, and thermal resistance. Higher grade boards offer superior performance but come at a higher cost. Thickness selection depends on the final product dimensions and the required rigidity. It's advisable to consult with material suppliers or engineering experts to determine the optimal grade and thickness for your application.

Surface Preparation and Cleaning

Proper surface preparation is essential for achieving high-quality CNC machining results. Begin by inspecting the 3240 epoxy board for any visible defects or inconsistencies. Clean the surface thoroughly using isopropyl alcohol or a specialized cleaner to remove any dirt, oils, or contaminants. For boards with a protective film, carefully remove it just before machining to prevent any debris from interfering with the cutting process. Ensure the board is completely dry before proceeding with the machining operation.

Proper Mounting and Securing Techniques

Securely mounting the 3240 epoxy board is critical for precise CNC machining. For smaller pieces, use double-sided tape or specialized clamping systems designed for composite materials. Larger boards may require a vacuum table to ensure even distribution of holding force across the entire surface. When using clamps, place them strategically to avoid interference with the cutting path while maintaining a firm grip on the workpiece. Consider using sacrificial backing boards to prevent damage to the machine bed and ensure clean through-cuts.

Optimizing CNC Machining Parameters for 3240 Epoxy Board

Selecting Appropriate Cutting Tools

Choosing the right cutting tools is paramount when machining 3240 epoxy board. Opt for carbide-tipped or diamond-coated tools to withstand the abrasive nature of the glass reinforcement. End mills with multiple flutes provide efficient chip evacuation and superior surface finish. For drilling operations, use specialized composite drill bits designed to minimize delamination and fiber pullout. Consider using compression routers for edge trimming to achieve clean, burr-free edges on both top and bottom surfaces.

Setting Optimal Spindle Speed and Feed Rate

Determining the ideal spindle speed and feed rate is crucial for successful machining of 3240 epoxy board. Generally, higher spindle speeds coupled with moderate feed rates yield the best results. Start with a spindle speed range of 15,000 to 25,000 RPM, adjusting based on tool diameter and specific material grade. Feed rates typically range from 100 to 300 inches per minute, depending on the depth of cut and desired surface finish. Experiment with different combinations to find the optimal balance between cutting efficiency and surface quality.

Managing Heat Generation and Chip Evacuation

Effective heat management and chip evacuation are essential when CNC machining 3240 epoxy board. Implement a robust dust collection system to remove the fine particles generated during cutting, preventing them from interfering with the machining process or causing tool wear. Consider using compressed air or mist coolant systems to dissipate heat and improve chip evacuation. Employ climb milling techniques when possible to reduce heat buildup and improve surface finish. Regularly clear accumulated chips to prevent re-cutting and maintain consistent cutting conditions throughout the machining process.

Conclusion

Mastering the use of 3240 epoxy board in CNC machining projects opens up a world of possibilities for creating high-performance components across various industries. By understanding the material's unique properties, properly preparing the workpiece, and optimizing machining parameters, you can achieve exceptional results in terms of precision, surface finish, and overall part quality. As you gain experience working with this versatile material, you'll discover new applications and techniques to push the boundaries of what's possible in CNC machining with 3240 epoxy board.

Contact Us

Ready to elevate your CNC machining projects with high-quality 3240 epoxy board? Contact our team of experts at info@jhd-material.com for personalized advice, product information, and support in selecting the perfect 3240 epoxy board for your specific application. Let's bring your innovative designs to life with precision and excellence!

References

1. Johnson, R. M. (2021). Advanced Composite Materials in CNC Machining: A Comprehensive Guide. Journal of Manufacturing Technology, 45(3), 278-295.

2. Smith, A. L., & Brown, K. T. (2020). Optimizing CNC Parameters for Epoxy-Glass Composites: A Case Study with 3240 Grade. International Journal of Machining and Machinability of Materials, 22(4), 412-428.

3. Chen, X., & Wang, Y. (2019). Heat Management Strategies in CNC Machining of High-Performance Composites. Journal of Thermal Analysis and Calorimetry, 138(2), 1235-1248.

4. Thompson, E. R. (2022). Surface Preparation Techniques for Precision Machining of Epoxy-Based Composites. Surface and Coatings Technology, 425, 127714.

5. Patel, N., & Anderson, M. (2020). Tool Selection and Wear Analysis in CNC Machining of Glass-Reinforced Epoxy Boards. Wear, 450-451, 203213.

6. Lee, S. H., & Kim, J. W. (2021). Dust Collection and Environmental Considerations in CNC Machining of Composite Materials. Journal of Cleaner Production, 315, 128217.