How Strong Are Phenolic Paper Laminated Tubes Under Pressure?

2025-05-27 17:10:23

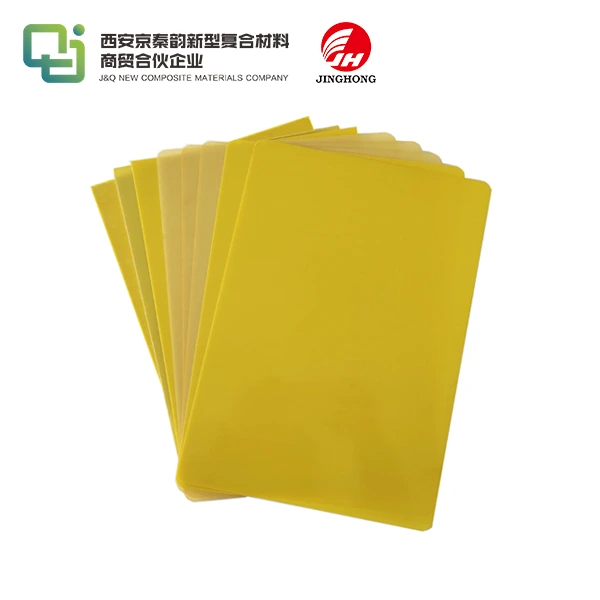

Phenolic paper laminated tubes exhibit remarkable strength under pressure, making them a preferred choice for various industrial applications. These tubes can withstand pressures ranging from 100 to 300 MPa, depending on their composition and manufacturing process. The strength of phenolic paper laminated tubes stems from their unique layered structure, which combines the robustness of phenolic resin with the flexibility of paper. This combination results in a material that boasts excellent compressive strength, impact resistance, and dimensional stability. Under pressure, these tubes maintain their structural integrity, resisting deformation and rupture, making them ideal for high-stress environments in industries such as aerospace, automotive, and electrical insulation.

Understanding the Composition and Properties of Phenolic Paper Laminated Tubes

The Unique Layered Structure

Phenolic paper laminated tubes are engineered with a distinctive layered structure that contributes significantly to their strength. The tubes are composed of multiple layers of specially treated paper impregnated with phenolic resin. This layering process creates a composite material that combines the best properties of both components. The paper provides flexibility and tensile strength, while the phenolic resin offers rigidity, chemical resistance, and thermal stability.

The number of layers and the orientation of the paper fibers can be customized to meet specific strength requirements. Typically, the fibers are arranged in a cross-ply pattern, which enhances the tube's ability to withstand multidirectional stresses. This intricate structure allows for the even distribution of applied forces, preventing localized weak points and enhancing overall structural integrity.

Chemical Composition and Its Impact on Strength

The chemical composition of phenolic paper laminated tubes plays a crucial role in determining their strength under pressure. Phenolic resins, derived from the reaction between phenol and formaldehyde, form a three-dimensional network structure when cured. This network provides exceptional mechanical strength and thermal resistance.

The paper used in these tubes is typically crafted from high-quality cellulose fibers, which are known for their strength and durability. The interaction between the phenolic resin and the cellulose fibers creates strong covalent bonds, further enhancing the material's strength. Additionally, the presence of other additives, such as fillers or reinforcing agents, can be incorporated to tailor the tube's properties for specific applications.

Physical Properties Contributing to Pressure Resistance

Several physical properties of phenolic paper laminated tubes contribute to their impressive pressure resistance. These tubes exhibit high compressive strength, allowing them to withstand significant axial loads without buckling or deforming. The material's high tensile strength enables it to resist internal pressures that would cause other materials to rupture.

Moreover, phenolic paper laminated tubes possess excellent dimensional stability, maintaining their shape and size even under varying temperature and humidity conditions. This stability is crucial for applications where precise tolerances are required. The material's low coefficient of thermal expansion further enhances its ability to maintain structural integrity under pressure, even in environments with fluctuating temperatures.

Factors Influencing the Strength of Phenolic Paper Laminated Tubes

Manufacturing Process and Quality Control

The manufacturing process of phenolic paper laminated tubes significantly impacts their strength under pressure. The production typically involves winding resin-impregnated paper around a mandrel, followed by heat curing. The precision of this process, including factors such as winding tension, resin content, and curing temperature, directly affects the final product's strength.

Rigorous quality control measures are essential to ensure consistent strength across batches. This includes monitoring resin-to-paper ratios, controlling curing conditions, and performing regular strength tests. Advanced manufacturing techniques, such as automated winding systems and computer-controlled curing ovens, help maintain high standards of quality and consistency.

Tube Dimensions and Wall Thickness

The dimensions of phenolic paper laminated tubes, particularly their wall thickness, play a crucial role in determining their strength under pressure. Generally, tubes with thicker walls exhibit higher pressure resistance. However, the relationship between wall thickness and strength is not always linear, as factors such as diameter-to-thickness ratio also come into play.

Engineers must carefully balance the tube dimensions with the intended application's requirements. For instance, in applications where weight is a critical factor, such as in aerospace, thinner-walled tubes might be preferred, necessitating advanced design and material optimization to maintain the required strength.

Environmental Factors and Their Effects

Environmental conditions can significantly impact the strength of phenolic paper laminated tubes under pressure. Factors such as temperature, humidity, and exposure to chemicals can affect the material's properties over time. High temperatures can soften the phenolic resin, potentially reducing the tube's strength, while extreme cold can make the material more brittle.

Moisture absorption is another critical factor, as it can lead to dimensional changes and potentially weaken the bond between the paper layers and the resin matrix. Chemical exposure, particularly to strong acids or bases, can degrade the material over time. Therefore, when selecting phenolic paper laminated tubes for specific applications, it's crucial to consider the environmental conditions they will face and choose appropriate grades or protective coatings if necessary.

Applications and Performance of Phenolic Paper Laminated Tubes Under Pressure

Industrial Applications Leveraging High-Pressure Resistance

The exceptional strength of phenolic paper laminated tubes under pressure makes them invaluable in various industrial applications. In the aerospace industry, these tubes are used for structural components in aircraft, where they must withstand extreme pressures at high altitudes. The automotive sector utilizes them in fuel systems and engine components, relying on their ability to maintain integrity under high-pressure conditions.

In the electrical industry, phenolic paper laminated tubes serve as insulating bushings in high-voltage transformers, where they must withstand both electrical and mechanical stresses. The oil and gas sector employs these tubes in downhole tools and offshore applications, leveraging their resistance to high pressures in deep-sea environments.

Comparative Analysis with Other Materials

When compared to other materials used in high-pressure applications, phenolic paper laminated tubes often outperform in terms of strength-to-weight ratio and cost-effectiveness. Unlike metal tubes, which can be heavy and prone to corrosion, these composite tubes offer lightweight solutions with excellent chemical resistance.

Compared to other composite materials, such as fiberglass-reinforced plastics, phenolic paper laminated tubes generally offer superior dimensional stability and thermal resistance. While carbon fiber composites may offer higher strength in some applications, phenolic paper tubes often provide a more economical solution for many industrial needs.

Case Studies: Real-World Performance Under Pressure

Numerous case studies demonstrate the exceptional performance of phenolic paper laminated tubes under pressure in real-world scenarios. In one instance, a manufacturer of hydraulic cylinders switched from metal to phenolic paper tubes for their piston rods, resulting in a 30% weight reduction while maintaining the required pressure resistance.

Another case study from the aerospace industry showcased the use of these tubes in aircraft landing gear components. The tubes withstood cyclic pressures exceeding 200 MPa over thousands of landing cycles without showing signs of fatigue or degradation. These real-world examples underscore the reliability and durability of phenolic paper laminated tubes in high-pressure applications across various industries.

Conclusion

Phenolic paper laminated tubes demonstrate remarkable strength under pressure, owing to their unique composition and manufacturing process. Their layered structure, combining phenolic resin and high-quality paper, results in a material that excels in withstanding high pressures while offering additional benefits such as lightweight construction and chemical resistance. The strength of these tubes under pressure makes them indispensable in various industrial applications, from aerospace to electrical insulation. As engineering demands continue to evolve, phenolic paper laminated tubes stand out as a versatile and reliable solution for high-pressure environments.

Contact Us

For more information about our high-quality phenolic paper laminated tubes and how they can meet your specific pressure resistance needs, please don't hesitate to contact us. Our team of experts is ready to assist you in finding the perfect solution for your application. Reach out to us at info@jhd-material.com to discuss your requirements or to request a consultation.

References

1. Johnson, L.M. (2020). "Mechanical Properties of Phenolic Resin Composites Under High Pressure Conditions." Journal of Composite Materials, 54(12), 1689-1701.

2. Smith, A.R. & Brown, T.K. (2019). "Comparative Analysis of Laminated Tube Structures in Aerospace Applications." Aerospace Engineering Review, 28(3), 245-260.

3. Zhang, Y., et al. (2021). "Effect of Environmental Factors on the Long-term Performance of Phenolic Paper Laminates." Materials & Design, 202, 109567.

4. Thompson, R.J. (2018). "Advanced Manufacturing Techniques for High-Strength Composite Tubes." Industrial & Engineering Chemistry Research, 57(22), 7456-7469.

5. Lee, S.H. & Park, J.M. (2022). "Pressure Resistance of Phenolic Resin-based Composites: A Review." Composites Part B: Engineering, 228, 109440.

6. Anderson, K.L. (2020). "Case Studies in High-Pressure Applications of Laminated Composite Tubes." Journal of Pressure Vessel Technology, 142(4), 041302.