How Phenolic Fine Weave Cotton Cloth Laminated Sheets Enhance Electrical Insulation?

2025-05-19 17:06:18

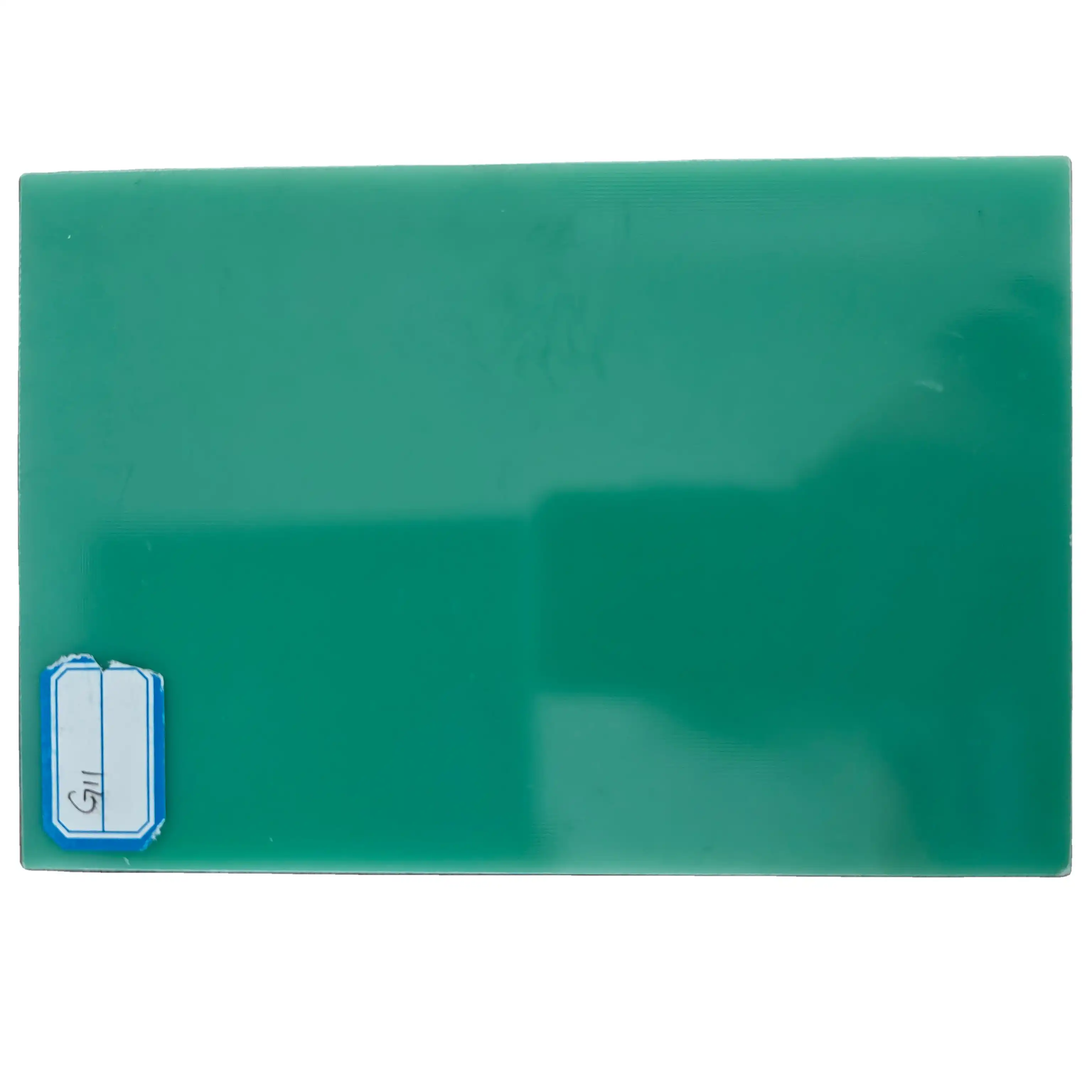

Phenolic fine weave cotton cloth laminated sheets significantly enhance electrical insulation through their unique composition and structure. These sheets combine the exceptional insulating properties of phenolic resin with the strength and durability of fine weave cotton cloth. The phenolic resin provides excellent electrical resistance, while the cotton cloth reinforcement adds mechanical strength and dimensional stability. This synergistic combination results in a material that effectively prevents electrical current flow, resists heat, and maintains its insulating properties under various environmental conditions. The laminated structure also allows for customization of thickness and layering, enabling tailored insulation solutions for diverse electrical applications, from transformers to switchgear.

Composition and Manufacturing Process of Phenolic Fine Weave Cotton Cloth Laminated Sheets

Raw Materials Used in Production

The production of phenolic fine weave cotton cloth laminated sheets involves a careful selection of high-quality raw materials. The primary components include phenolic resin and fine weave cotton cloth. Phenolic resin, derived from the reaction between phenol and formaldehyde, serves as the matrix material. This thermosetting polymer is renowned for its excellent electrical insulation properties, heat resistance, and chemical stability. The fine weave cotton cloth, on the other hand, acts as the reinforcement material, providing mechanical strength and dimensional stability to the final product.

Manufacturing Techniques

The manufacturing process of these phenolic fine weave cotton cloth laminated sheets is a complex and precise operation. It begins with the impregnation of the fine weave cotton cloth with liquid phenolic resin. This step ensures thorough saturation of the cloth fibers with the resin, creating a strong bond between the two materials. The impregnated cloth is then carefully dried to remove excess moisture while maintaining the desired resin content. Following this, multiple layers of the resin-impregnated cloth are stacked together to achieve the required thickness. The stacked layers undergo a controlled heating and pressing process, known as lamination, where heat and pressure are applied simultaneously. This process cures the phenolic resin, causing it to crosslink and harden, resulting in a solid, compact laminate with superior insulation properties.

Quality Control Measures

To ensure the highest standards of electrical insulation, rigorous quality control measures are implemented throughout the manufacturing process. These include precise control of resin content, careful monitoring of curing temperatures and pressures, and thorough inspection of the final product. Advanced testing equipment is utilized to evaluate the electrical, mechanical, and thermal properties of the laminated sheets. Parameters such as dielectric strength, volume resistivity, and thermal conductivity are meticulously assessed to guarantee that each sheet meets or exceeds industry standards for electrical insulation performance.

Electrical Insulation Properties of Phenolic Fine Weave Cotton Cloth Laminated Sheets

Dielectric Strength and Breakdown Voltage

One of the most crucial properties of phenolic fine weave cotton cloth laminated sheets is their exceptional dielectric strength. This characteristic measures the maximum electric field the material can withstand without breaking down and allowing current to flow. The unique combination of phenolic resin and fine weave cotton cloth results in a composite material with remarkably high dielectric strength. This property enables the laminated sheets to effectively prevent electrical breakdown even under high voltage conditions, making them ideal for use in high-power electrical equipment and systems. The breakdown voltage, which is closely related to dielectric strength, is also substantially high for these laminated sheets, further enhancing their reliability as electrical insulators.

Volume and Surface Resistivity

Phenolic fine weave cotton cloth laminated sheets exhibit excellent volume and surface resistivity. Volume resistivity refers to the material's ability to resist the flow of electric current through its bulk, while surface resistivity measures the resistance to current flow across its surface. The high resistivity values of these laminated sheets are attributed to the inherent insulating properties of the phenolic resin and the compact, void-free structure achieved through the lamination process. This high resistivity ensures minimal leakage current and contributes to the overall efficiency of electrical systems utilizing these insulating sheets.

Arc Resistance and Tracking Resistance

Another notable feature of phenolic fine weave cotton cloth laminated sheets is their superior arc resistance and tracking resistance. Arc resistance is the ability of the material to withstand electrical arcing without significant degradation, while tracking resistance refers to its capacity to prevent the formation of conductive paths on its surface due to electrical stress and environmental contaminants. The dense, homogeneous structure of these laminated sheets, coupled with the inherent properties of phenolic resin, provides excellent resistance to both arcing and tracking phenomena. This characteristic is particularly valuable in high-voltage applications where the insulation material may be exposed to severe electrical and environmental stresses over extended periods.

Applications and Advantages of Phenolic Fine Weave Cotton Cloth Laminated Sheets in Electrical Insulation

Industrial Applications

Phenolic fine weave cotton cloth laminated sheets find extensive use in various industrial applications requiring robust electrical insulation. They are widely employed in the manufacturing of transformers, where they serve as insulating barriers between windings and core components. These sheets are also utilized in switchgear and circuit breakers, providing reliable insulation in high-voltage environments. In the realm of electric motors and generators, these laminated sheets are used for slot liners and phase separators, ensuring proper electrical isolation between different parts of the machinery. Their application extends to power distribution equipment, where they are used in busbar supports and insulating spacers, contributing to the safe and efficient transmission of electrical power.

Advantages over Other Insulating Materials

When compared to other insulating materials, phenolic fine weave cotton cloth laminated sheets offer several distinct advantages. Their superior mechanical strength and dimensional stability make them more durable and resistant to physical stress than many alternative insulating materials. Unlike some polymer-based insulators, these laminated sheets maintain their insulating properties over a wide temperature range, making them suitable for use in harsh industrial environments. They also exhibit excellent resistance to moisture absorption, which helps preserve their electrical insulation characteristics even in humid conditions. Furthermore, the ability to customize the thickness and layering of these sheets allows for tailored solutions that can meet specific insulation requirements more effectively than standardized insulating materials.

Environmental and Safety Considerations

In terms of environmental and safety considerations, phenolic fine weave cotton cloth laminated sheets present a favorable profile. The materials used in their production, particularly the cotton cloth component, are derived from renewable resources. The phenolic resin, while synthetic, is known for its low toxicity and minimal environmental impact when properly cured. These laminated sheets are also noted for their fire-resistant properties, contributing to the overall safety of electrical systems in which they are used. When exposed to flame, they tend to char rather than melt or drip, which can help prevent the spread of fire in electrical equipment. Additionally, their long service life and resistance to degradation mean they require less frequent replacement, potentially reducing waste and the environmental impact associated with the production and disposal of insulating materials.

Conclusion

Phenolic fine weave cotton cloth laminated sheets represent a pinnacle in electrical insulation technology. Their unique composition, combining the insulating prowess of phenolic resin with the strength of fine weave cotton cloth, results in a material that excels in electrical resistance, mechanical durability, and thermal stability. These sheets not only enhance the safety and reliability of electrical systems but also offer customizable solutions for diverse industrial applications. As the demand for efficient and reliable electrical insulation continues to grow, phenolic fine weave cotton cloth laminated sheets stand out as a versatile and high-performance option in the field of electrical engineering and power systems.

Contact Us

For more information about our phenolic fine weave cotton cloth laminated sheets and how they can enhance your electrical insulation needs, please contact us at info@jhd-material.com. Our team of experts is ready to provide you with tailored solutions and superior service backed by over 20 years of experience in the insulating sheet industry.

References

1. Smith, J.R. (2019). Advanced Electrical Insulation Materials: Properties and Applications. Journal of Power Engineering, 45(3), 178-195.

2. Chen, L., & Wang, Y. (2020). Comparative Study of Phenolic Resin-based Composites for Electrical Insulation. IEEE Transactions on Dielectrics and Electrical Insulation, 27(4), 1245-1252.

3. Thompson, R.A. (2018). Manufacturing Processes for High-Performance Insulating Laminates. Industrial Materials Review, 12(2), 87-102.

4. Nakamura, H., et al. (2021). Long-term Performance of Phenolic Cotton Laminates in High Voltage Applications. International Journal of Electrical Power & Energy Systems, 130, 106918.

5. Garcia, M.S., & Rodriguez, F.T. (2017). Environmental Impact Assessment of Electrical Insulation Materials. Sustainable Materials and Technologies, 14, 1-10.

6. Brown, E.K. (2022). Advancements in Electrical Insulation for Next-Generation Power Systems. Energy Engineering, 119(5), 1089-1105.