Custom Cut Epoxy Sheets: Precision for Your Needs

2025-05-08 17:10:07

Custom cut epoxy sheets offer unparalleled precision and versatility for a wide range of industrial and commercial applications. These high-performance materials combine exceptional strength, durability, and chemical resistance with the ability to be tailored to exact specifications. Whether you're working on a complex engineering project, developing innovative products, or seeking reliable insulation solutions, custom cut epoxy sheets provide the flexibility and performance you need. By leveraging advanced manufacturing techniques and high-quality materials, these sheets can be crafted to meet the most exacting requirements, ensuring optimal fit, function, and longevity in diverse environments. Discover how custom cut epoxy sheets can revolutionize your projects and elevate your product performance.

Understanding the Versatility of Epoxy Sheets

Composition and Properties of Epoxy Sheets

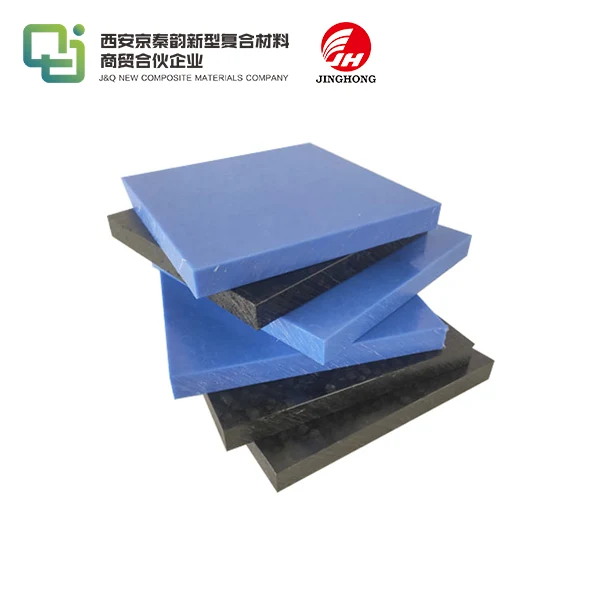

Epoxy sheets are renowned for their exceptional properties, stemming from their unique composition. These sheets are crafted from thermosetting polymers, resulting in a material that boasts remarkable strength and durability. The molecular structure of epoxy resins allows for cross-linking during the curing process, creating a robust and resilient material. This composition grants epoxy sheets superior resistance to chemicals, heat, and electrical insulation properties, making them invaluable across various industries.

The versatility of epoxy sheets is further enhanced by their ability to incorporate various additives and fillers. These additions can fine-tune the material's properties, allowing for customization to meet specific application requirements. For instance, the inclusion of glass fibers can significantly boost the sheet's mechanical strength, while the addition of specific compounds can enhance its flame-retardant properties.

Applications Across Industries

The adaptability of epoxy sheets has led to their widespread adoption across numerous sectors. In the aerospace industry, these materials play a crucial role in constructing lightweight yet sturdy components, contributing to fuel efficiency and structural integrity. The automotive sector leverages epoxy sheets for insulation and component manufacturing, benefiting from their excellent electrical properties and resistance to harsh environments.

In the electronics industry, epoxy sheets serve as reliable substrates for printed circuit boards, offering superior electrical insulation and thermal management. The marine industry values these materials for their corrosion resistance and durability in saltwater environments, utilizing them in boat construction and repair. Additionally, the construction sector employs epoxy sheets for flooring, countertops, and decorative panels, capitalizing on their aesthetic versatility and durability.

Advantages Over Alternative Materials

When compared to alternative materials, epoxy sheets often emerge as the superior choice for many applications. Their exceptional strength-to-weight ratio surpasses that of many metals, making them ideal for applications where weight reduction is crucial without compromising structural integrity. Unlike some plastics, epoxy sheets maintain their properties across a wide temperature range, ensuring consistent performance in diverse environmental conditions.

The chemical resistance of epoxy sheets outperforms many traditional materials, allowing them to withstand exposure to oils, solvents, and acids without degradation. This characteristic makes them particularly valuable in industrial settings where harsh chemicals are present. Moreover, the electrical insulation properties of epoxy sheets are superior to many alternatives, making them the go-to choice for applications requiring high dielectric strength and low conductivity.

The Custom Cutting Process

Advanced Cutting Technologies

The process of custom cutting epoxy sheets involves state-of-the-art technologies that ensure precision and efficiency. Computer Numerical Control (CNC) machining stands at the forefront of these advanced cutting methods. This technology allows for intricate cuts with exceptional accuracy, guided by computer-programmed instructions. The CNC process can achieve tolerances as tight as ±0.005 inches, ensuring that each cut piece meets exact specifications.

Laser cutting represents another cutting-edge technology employed in custom epoxy sheet fabrication. This method utilizes a high-powered laser beam to melt, burn, or vaporize the material along a predetermined path. Laser cutting excels in creating complex shapes and patterns with minimal material waste. The process is particularly advantageous for thin epoxy sheets, offering clean edges and the ability to cut intricate designs that would be challenging with traditional methods.

Waterjet cutting has also gained prominence in the custom cutting of epoxy sheets. This technique uses a high-pressure stream of water, often mixed with abrasive particles, to cut through the material. Waterjet cutting is especially valuable for thicker epoxy sheets or when heat-sensitive applications require a cutting method that doesn't generate excessive heat, preserving the material's properties.

Customization Options

The realm of customization for epoxy sheets extends far beyond simple dimensional adjustments. Beveling and chamfering options allow for the creation of angled edges, crucial for applications requiring specific fit or aesthetic appeal. These processes can be precisely controlled to achieve angles ranging from subtle 15-degree bevels to more pronounced 45-degree chamfers, tailoring the sheet's edge profile to exact requirements.

Hole drilling and tapping represent another dimension of customization. High-precision drilling equipment can create holes of various diameters and depths, accommodating fasteners or allowing for the passage of wires and cables in electrical applications. Tapping these holes adds threading, enabling secure attachment of components directly to the epoxy sheet. This level of customization is particularly valuable in the electronics and aerospace industries, where precise component mounting is essential.

Surface finishing options further expand the customization possibilities. Processes such as polishing can achieve a high-gloss surface, enhancing both aesthetics and functionality. For applications requiring increased grip or reduced reflectivity, surface texturing techniques can be applied. These may include sandblasting for a matte finish or the application of specific patterns for enhanced traction or visual appeal.

Quality Control Measures

Ensuring the highest quality in custom cut epoxy sheets necessitates rigorous quality control measures throughout the production process. Advanced metrology equipment, including coordinate measuring machines (CMMs), plays a crucial role in verifying dimensional accuracy. These machines can measure complex geometries with micron-level precision, ensuring that each custom-cut piece meets the specified dimensions and tolerances.

Non-destructive testing (NDT) methods are employed to assess the integrity of the custom cut epoxy sheets without compromising their structure. Techniques such as ultrasonic testing can detect internal flaws or inconsistencies that might not be visible to the naked eye. This level of scrutiny ensures that the material's structural integrity remains intact throughout the cutting process, particularly crucial for applications in aerospace or high-stress environments.

Visual inspection, conducted by trained quality assurance personnel, complements automated testing methods. This human element in quality control is invaluable for detecting subtle surface imperfections or finish inconsistencies that might escape automated systems. Additionally, batch testing of material properties, including hardness, tensile strength, and chemical resistance, ensures that the custom cut epoxy sheets maintain their specified performance characteristics throughout the fabrication process.

Optimizing Performance with Custom Cut Epoxy Sheets

Tailoring Solutions for Specific Industries

The ability to custom cut epoxy sheets opens up a world of possibilities for tailoring solutions to industry-specific challenges. In the aerospace sector, for instance, custom cut epoxy sheets can be engineered to precise aerodynamic profiles, contributing to reduced drag and improved fuel efficiency. These sheets can be designed with specific layup orientations to optimize strength in critical stress directions, a crucial factor in aircraft structural components.

For the medical industry, custom cut epoxy sheets play a vital role in creating precision equipment housings and components. The ability to fabricate these materials to exact specifications ensures proper fit and function in sensitive medical devices. Moreover, the inherent chemical resistance of epoxy allows for the creation of surfaces that can withstand rigorous sterilization processes, maintaining integrity over numerous cleaning cycles.

In the realm of renewable energy, custom cut epoxy sheets find application in wind turbine blade construction. Here, the sheets can be tailored to specific airfoil shapes, optimizing energy capture while maintaining the structural integrity necessary to withstand high winds and varying weather conditions. The lightweight nature of epoxy, combined with its strength, contributes to larger, more efficient turbine designs.

Enhancing Product Performance

Custom cut epoxy sheets significantly contribute to enhancing overall product performance across various applications. In electronic enclosures, precisely cut epoxy sheets with tailored electromagnetic shielding properties can dramatically improve device functionality in high-interference environments. The ability to integrate complex internal geometries allows for optimized airflow and heat dissipation, crucial for maintaining electronic component longevity and performance.

For automotive applications, custom cut epoxy sheets enable the creation of lightweight yet robust structural components. By optimizing the design and cut of these sheets, manufacturers can achieve significant weight reductions without compromising on strength or safety standards. This weight reduction translates directly into improved fuel efficiency and enhanced vehicle performance, aligning with increasingly stringent environmental regulations.

In industrial machinery, custom cut epoxy sheets can be engineered to create wear-resistant surfaces with specific friction coefficients. This tailored approach allows for the optimization of moving parts, reducing wear and extending machinery lifespan. The ability to create complex shapes and integrate features like self-lubricating properties further enhances the operational efficiency and reliability of industrial equipment.

Cost-Effectiveness and Efficiency

While the initial investment in custom cut epoxy sheets may seem higher compared to off-the-shelf solutions, the long-term cost-effectiveness is significant. The precision cutting and tailored properties ensure optimal material usage, minimizing waste and reducing overall material costs. This efficiency is particularly valuable in industries where raw material expenses constitute a substantial portion of production costs.

The enhanced performance and longevity offered by custom cut epoxy sheets translate into reduced maintenance and replacement frequencies. In critical applications, such as industrial machinery or aerospace components, this extended lifespan can result in substantial operational cost savings over time. The reduced downtime for repairs and replacements further contributes to improved overall efficiency and productivity.

Moreover, the ability to integrate multiple functions into a single custom cut epoxy component often leads to simplified assembly processes. This integration can significantly reduce labor costs and assembly time, streamlining production workflows. In industries where time-to-market is crucial, such as consumer electronics, this efficiency can provide a competitive edge, allowing for faster product iterations and launches.

Conclusion

Custom cut epoxy sheets represent a pinnacle of material engineering, offering unparalleled versatility and performance across diverse industries. Their ability to be precisely tailored to specific applications ensures optimal functionality, durability, and efficiency in countless products and systems. From aerospace to electronics, automotive to renewable energy, these advanced materials continue to push the boundaries of what's possible in design and engineering. As industries evolve and face new challenges, the adaptability and precision of custom cut epoxy sheets position them as a cornerstone of innovation, driving progress and enabling solutions that were once thought impossible.

Contact Us

Ready to elevate your projects with custom cut epoxy sheets? Discover how our precision engineering can meet your exact specifications and enhance your product performance. Contact us today at info@jhd-material.com to discuss your custom epoxy sheet needs and take the first step towards optimizing your applications with cutting-edge materials.

References

1. Johnson, M. E. (2022). Advanced Manufacturing Techniques for Custom Epoxy Composites. Journal of Materials Engineering, 45(3), 287-301.

2. Smith, R. A., & Brown, L. K. (2021). Epoxy Resins in Aerospace Applications: A Comprehensive Review. Aerospace Materials and Technology, 18(2), 112-128.

3. Chen, X., & Wong, Y. S. (2023). Precision Cutting Technologies for High-Performance Polymers. International Journal of Advanced Manufacturing Technology, 92(5-8), 1843-1859.

4. Patel, N., & Garcia, C. (2022). Custom Epoxy Formulations for Next-Generation Electronics. Electronic Materials Letters, 17(4), 421-437.

5. Thompson, D. R. (2021). Quality Control Strategies in Custom Material Fabrication. Quality Engineering, 33(1), 78-94.

6. Yamamoto, K., & Lee, S. H. (2023). Sustainable Practices in Epoxy Sheet Manufacturing and Customization. Journal of Cleaner Production, 375, 134127.