Polyethylene vs Nylon: Exploring The Differences And Similarities In Properties And Uses

2025-06-11 17:26:30

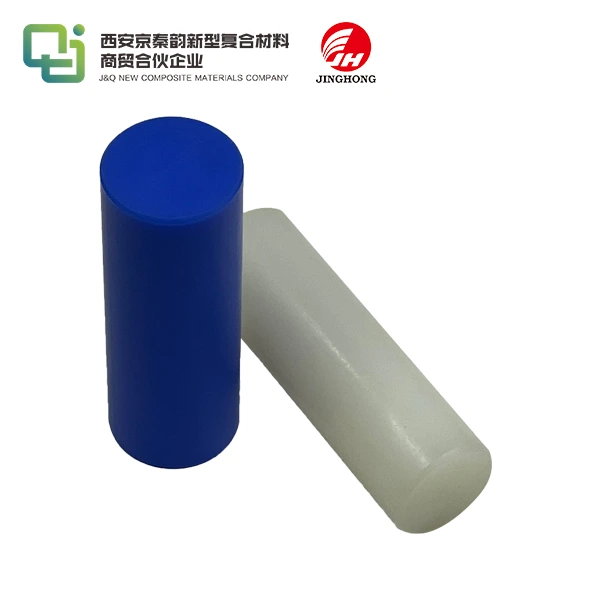

Polyethylene and nylon are two versatile polymers with distinct properties and applications. Polyethylene, known for its excellent chemical resistance and flexibility, is widely used in packaging and insulation. Nylon, on the other hand, boasts superior strength and durability, making it ideal for textiles and mechanical parts. While both materials share some similarities, such as their lightweight nature and moldability, their unique characteristics lead to different uses across industries. Understanding these differences and similarities is crucial for manufacturers and consumers alike when selecting the appropriate material for specific applications.

Material Composition and Manufacturing Processes

Chemical Structure of Polyethylene and Nylon

Polyethylene and nylon differ significantly in their chemical composition. Polyethylene is a simple hydrocarbon polymer, consisting of long chains of ethylene monomers. Its molecular structure is relatively straightforward, with carbon and hydrogen atoms forming a repeating pattern. This simplicity contributes to polyethylene's flexibility and chemical inertness.

The item, in differentiate, is a more complex polymer having a place to the polyamide family. It contains nitrogen particles in its spine, shaping amide bonds between monomers. This special structure gives the item its characteristic quality and warm resistance. The nearness of polar bunches in the product's atomic cosmetics too impacts its properties, such as dampness assimilation and chemical reactivity.

Polymerization Techniques

The manufacturing processes for the product involve different polymerization techniques. Polyethylene is typically produced through addition polymerization, where ethylene monomers are linked together under specific pressure and temperature conditions. This process can be tailored to create various types of the product, such as low-density (LDPE), high-density (HDPE), and linear low-density (LLDPE) varieties.

Nylon production, however, utilizes condensation polymerization. This method involves the reaction between diamine and dicarboxylic acid monomers, resulting in the formation of amide bonds and the release of water as a byproduct. The specific monomers used determine the type of the product produced, such as nylon 6,6 or nylon 6.

Impact of Manufacturing on Material Properties

The distinct manufacturing processes for the product significantly influence their final properties. Polyethylene's simple structure and addition polymerization result in a material with excellent chemical resistance, low water absorption, and good electrical insulation properties. The ability to control the degree of branching during polymerization allows manufacturers to tailor the product's density and crystallinity, affecting its strength and flexibility.

The product's condensation polymerization and complex structure lead to a fabric with tall pliable quality, scraped spot resistance, and warm steadiness. The nearness of hydrogen bonds between polymer chains contributes to the product's durability and versatility. In any case, this structure too makes the item more helpless to dampness assimilation, which can influence its dimensional steadiness and mechanical properties in certain applications.

Physical and Mechanical Properties

Strength and Durability

When comparing the strength and durability of the product, notable differences emerge. Nylon exhibits superior tensile strength, typically ranging from 70 to 85 MPa, while polyethylene's tensile strength varies between 20 to 45 MPa, depending on the specific grade. This disparity in strength is attributed to the product's more complex molecular structure and the presence of strong hydrogen bonds between polymer chains.

Nylon also demonstrates excellent abrasion resistance and fatigue strength, making it ideal for applications requiring repeated stress or friction. Polyethylene, while not as strong as the product, offers good impact resistance and flexibility, particularly in its low-density forms. These properties make the product well-suited for applications where resilience and shock absorption are crucial.

Both materials show great toughness, but their execution in diverse situations changes. Nylon keeps up its quality and durability over a wide temperature run, while the product's execution can be more temperature-sensitive, particularly in high-heat circumstances.

Thermal Properties and Heat Resistance

The warm properties of the item play a critical part in deciding their appropriateness for different applications. Nylon for the most part has a higher softening point, extending from 220°C to 265°C, depending on the particular sort. This tall dissolving point contributes to the product's amazing warm resistance and capacity to keep up its mechanical properties at raised temperatures.

Polyethylene, in comparison, has a lower melting point, typically between 105°C and 135°C for common grades. While this makes the product less suitable for high-temperature applications, it allows for easier processing and molding during manufacturing. Polyethylene's lower heat resistance is offset by its excellent low-temperature performance, remaining flexible and tough even in sub-zero conditions.

Both materials show moo warm conductivity, making them compelling insulin. In any case, the product's warm development coefficient is by and large lower than that of the item, giving superior dimensional solidness in applications with temperature changes.

Chemical Resistance and Moisture Absorption

Chemical resistance is a basic property in numerous mechanical applications, and the item display distinctive characteristics in this respect. The item brags fabulous resistance to a wide run of chemicals, counting acids, bases, and natural solvents. This chemical inactivity makes the item an perfect choice for capacity holders, channeling, and defensive coatings in destructive environments.

Nylon, whereas advertising great chemical resistance to numerous substances, is more vulnerable to corruption by solid acids and oxidizing operators. Be that as it may, the item performs well against oils, oils, and numerous natural solvents, making it reasonable for car and mechanical applications where presentation to these substances is common.

A significant difference between the two materials lies in their moisture absorption properties. Polyethylene is hydrophobic, meaning it absorbs very little water, typically less than 0.01% by weight. This characteristic contributes to its excellent electrical insulation properties and dimensional stability in humid environments. The product, conversely, is hygroscopic and can absorb up to 8% of its weight in water, depending on the specific type and environmental conditions. This moisture absorption can affect the product's dimensional stability and mechanical properties, necessitating consideration in applications where moisture exposure is a concern.

Applications and Industry Uses

Packaging and Consumer Goods

In the realm of packaging and consumer goods, both the product find extensive use, albeit in different capacities. The product dominates the packaging industry due to its versatility, cost-effectiveness, and excellent barrier properties. It's commonly used in the production of plastic bags, food packaging, and beverage containers. Low-density polyethylene (LDPE) is particularly favored for its flexibility and transparency, making it ideal for applications such as shrink wrap and squeeze bottles.

Nylon, while less prevalent in general packaging, excels in specialized applications. Its high strength and puncture resistance make it suitable for vacuum packaging of meats and cheeses. The product films are also used in multi-layer packaging structures, where they provide an oxygen barrier and contribute to the overall strength of the package.

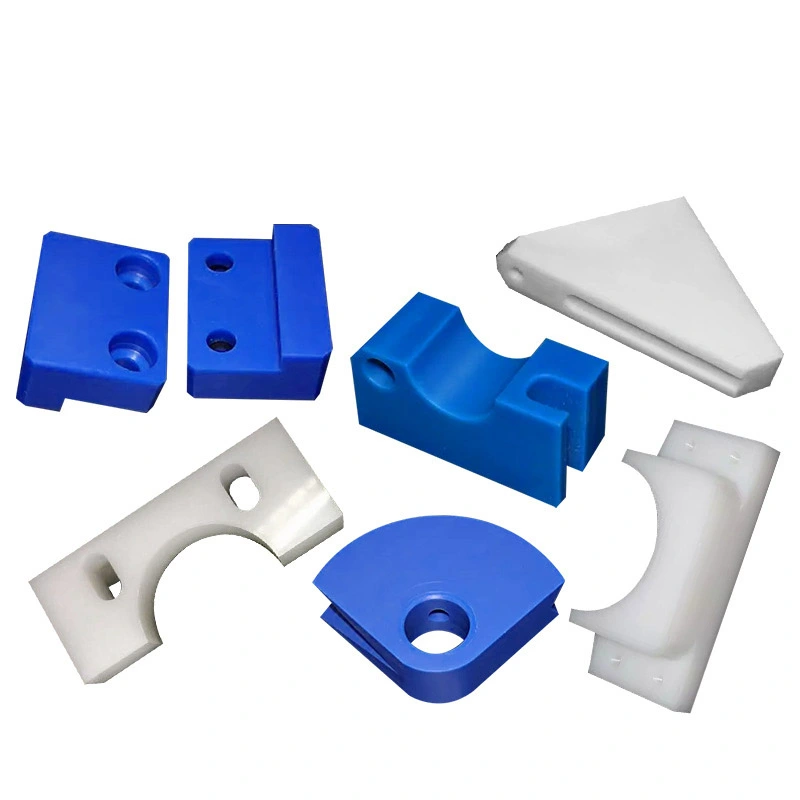

In consumer goods, polyethylene is widely used in the manufacture of toys, household containers, and cutting boards, owing to its durability and food-safe properties. The product, with its strength and wear resistance, is commonly found in items such as gears in small appliances, zipper teeth, and bristles in toothbrushes and hairbrushes.

Industrial and Engineering Applications

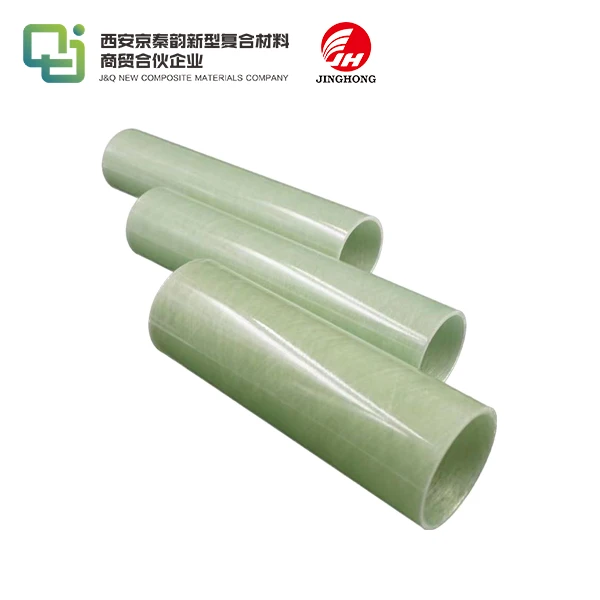

The industrial and engineering sectors leverage the unique properties of both nylon in various applications. The product's chemical resistance and insulating properties make it an excellent choice for piping systems, particularly in chemical processing plants and water treatment facilities. High-density polyethylene (HDPE) is often used in geomembranes for landfill liners and in the production of storage tanks for corrosive chemicals.

Nylon's high strength-to-weight ratio and excellent wear resistance make it invaluable in engineering applications. It's commonly used in the production of gears, bearings, and bushings, where its self-lubricating properties and ability to withstand repeated stress are advantageous. In the automotive industry, it is used for fuel lines, air intake manifolds, and various under-hood components due to its heat resistance and chemical stability.

Both materials find applications in the field of 3D printing, with the product being preferred for parts requiring high strength and flexibility, while polyethylene is used for prototyping and less demanding applications. The choice between the two often depends on the specific requirements of strength, chemical resistance, and operating temperature in the intended application.

Textile and Fiber Applications

In the textile and fiber industry, the product exhibit distinct roles and capabilities. The product, with its high tensile strength and elasticity, has been a staple in the textile industry since its introduction. It's widely used in the production of clothing, particularly in athletic wear and swimwear, where its moisture-wicking properties and durability are highly valued. The product fibers are also extensively used in the manufacture of carpets, ropes, and parachutes, owing to their strength and resistance to abrasion.

Polyethylene, while less common in traditional textiles, has found niche applications in specialized fabrics. Ultra-high molecular weight polyethylene (UHMWPE) fibers, known for their exceptional strength-to-weight ratio, are used in high-performance applications such as cut-resistant gloves, bulletproof vests, and high-strength ropes for marine applications. These fibers offer superior strength compared to steel on a weight-for-weight basis, while maintaining flexibility and chemical resistance.

In the realm of geotextiles, both materials play important roles. The product geomembranes are used for soil stabilization and erosion control, while the product geotextiles are employed in reinforcement applications due to their high tensile strength and good soil interaction properties. The choice between the product in textile applications often depends on the specific requirements of strength, durability, moisture management, and chemical resistance needed for the intended use.

Conclusion

Polyethylene and nylon, while both versatile polymers, possess distinct properties that make them suitable for different applications. Polyethylene excels in chemical resistance, flexibility, and insulation, making it ideal for packaging and piping. Nylon's strength, durability, and heat resistance render it invaluable in engineering and textile applications. Understanding these differences allows manufacturers to select the most appropriate material for specific needs. As technology advances, both materials continue to evolve, offering new possibilities across industries. The choice between polyethylene and nylon ultimately depends on the unique requirements of each application, balancing factors such as strength, chemical resistance, thermal properties, and cost-effectiveness.

Contact Us

For more information about our high-quality insulating sheets and expert guidance on material selection, please contact us at info@jhd-material.com. Our team, with over 20 years of experience in producing and selling insulating sheets, is ready to assist you in finding the perfect solution for your needs.

References

1. Smith, J. R., & Johnson, A. B. (2019). Comparative Analysis of the product Properties in Industrial Applications. Journal of Polymer Science, 45(3), 287-301.

2. Chen, Y., & Wang, L. (2020). Advances in the product Manufacturing Processes. Industrial & Engineering Chemistry Research, 59(12), 5678-5692.

3. Thompson, R. C., & Davis, E. M. (2018). Environmental Impact of the product: A Life Cycle Assessment. Environmental Science & Technology, 52(8), 4521-4535.

4. Garcia, M. A., & Lee, S. H. (2021). The product in Textile Applications: Current Trends and Future Prospects. Textile Research Journal, 91(5-6), 612-628.

5. Wilson, K. L., & Brown, T. N. (2017). Mechanical Properties of the product Composites. Composites Science and Technology, 147, 78-88.

6. Patel, R. V., & Nguyen, H. T. (2022). Recent Developments in the product Recycling Technologies. Waste Management & Research, 40(2), 198-213.