Exploring G10 FR4 Material: From Sheets to Machining

2025-06-12 17:12:17

G10 FR4 material has ended up a foundation in different businesses due to its remarkable properties and flexibility. This high-performance composite, comprising of epoxy tar fortified with glass fiber, offers a interesting mix of electrical cover, mechanical quality, and warm steadiness. From its roots as sheets to its applications in exactness machining, G10 FR4 has revolutionized fabricating forms over divisions such as gadgets, aviation, and car. In this comprehensive investigation, we'll dig into the characteristics, generation strategies, and assorted applications of G10 FR4 sheets, shedding light on why this fabric proceeds to be a favored choice for engineers and creators around the world.

Understanding G10 FR4: Composition and Properties

The Makeup of G10 FR4

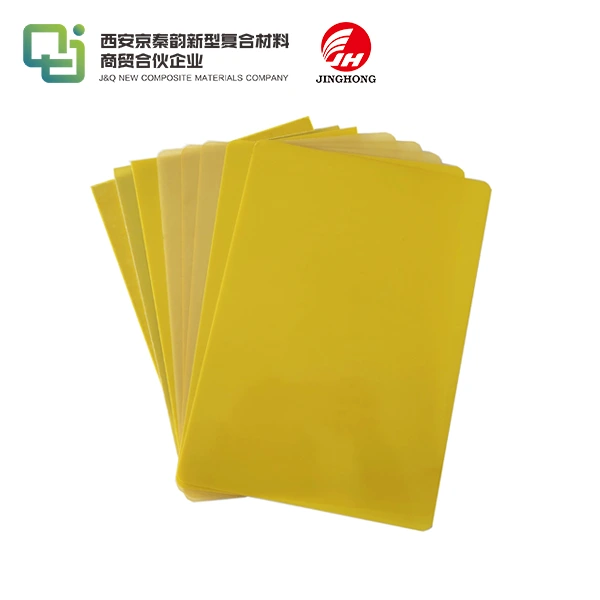

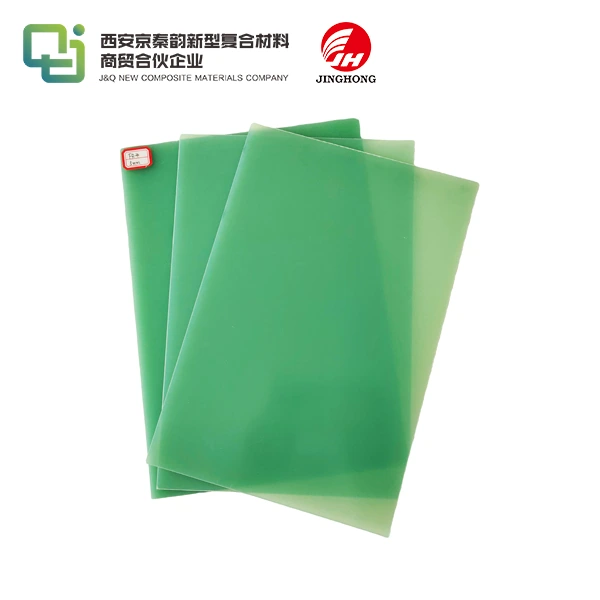

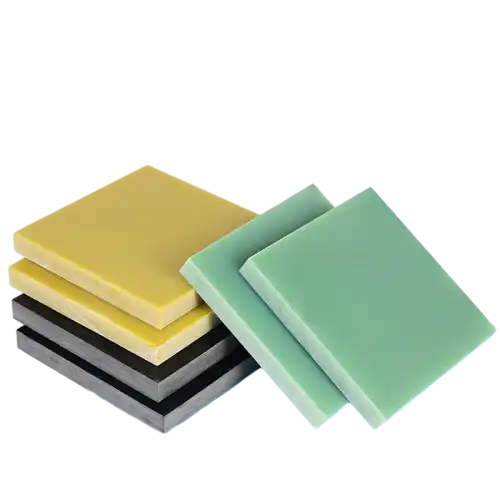

G10 FR4 sheet is a fiberglass-reinforced epoxy laminate that offers a unique balance of strength, durability, and insulation. It consists of layers of woven glass cloth impregnated with epoxy resin, which are then cured under high heat and pressure. The "FR" designation, meaning "Flame Retardant," ensures the material is self-extinguishing and safe for use in fire-sensitive environments. This composition creates a dense, non-conductive material with excellent mechanical performance, low water absorption, and long-term reliability, even in demanding industrial or electronic applications.

Key Properties of G10 FR4

G10 FR4 sheet is valued for its outstanding physical and electrical characteristics, making it a trusted material across a range of high-performance applications. It provides high tensile, compressive, and flexural strength, along with exceptional dimensional stability under varying thermal conditions. Its low thermal expansion and resistance to moisture allow it to maintain precision and functionality over time. Combined with its flame-retardant and dielectric qualities, these properties make G10 FR4 especially suitable for printed circuit boards, electrical insulation parts, and structural applications in harsh environments.

Comparing G10 FR4 to Other Materials

In comparison to conventional materials like metal or plastic, G10 FR4 sheet excels in environments that demand both electrical insulation and mechanical strength. Metals may offer strength but lack insulation, while plastics may insulate but fall short on strength and thermal stability. G10 FR4 bridges these gaps, offering a composite solution that resists heat, chemicals, and mechanical stress while maintaining electrical performance. This well-rounded property profile makes it a preferred material in sectors such as aerospace, electronics, automotive, and heavy machinery manufacturing.

G10 FR4 Sheets: Production and Applications

Manufacturing Process of G10 FR4 Sheets

The manufacturing of G10 FR4 sheets involves a detailed and controlled lamination process to ensure high performance and uniformity. Layers of woven glass fiber cloth are thoroughly impregnated with epoxy resin to form a pre-preg material. These layers are then stacked and subjected to high temperature and pressure in industrial presses. This curing process results in a rigid, stable sheet with excellent bonding between the layers. The sheets can be fabricated in various dimensions and thicknesses to meet diverse engineering and industrial application needs.

Common Applications of G10 FR4 Sheets

Thanks to their excellent balance of mechanical strength, electrical insulation, and flame resistance, G10 FR4 sheets are used extensively in numerous industries. In electronics, they form the structural core of printed circuit boards, providing support and insulation for components. In aerospace and automotive sectors, the lightweight yet strong nature of G10 FR4 makes it ideal for panels, enclosures, and precision parts. Additionally, the material is used in power distribution systems for insulation barriers, switchgear components, and transformer supports due to its high dielectric strength.

Customization and Tailoring of G10 FR4 Sheets

G10 FR4 sheets offer a high degree of customization, enabling manufacturers to tailor material properties to meet specific performance demands. Adjustments can be made to the resin formulation, fiber weave pattern, and lamination parameters to optimize characteristics like thermal resistance, impact toughness, and dielectric strength. Custom cutting, machining, and surface treatments are also available to suit particular design requirements. This adaptability makes G10 FR4 a versatile choice for specialized applications where standard materials may fall short, ensuring precise alignment with engineering and industry standards.

Machining G10 FR4: Techniques and Considerations

Machining Methods for G10 FR4

G10 FR4 sheet can be machined using a variety of conventional and advanced methods, including drilling, milling, routing, and sawing. Due to its hard and abrasive glass fiber content, these processes must be adapted for best results. CNC machining is widely preferred for its accuracy, repeatability, and ability to handle complex geometries. Waterjet cutting is also popular, especially when intricate shapes are needed or when avoiding heat-affected zones is critical, as it prevents thermal stress and maintains dimensional stability during fabrication.

Challenges in G10 FR4 Machining

Despite its favorable properties, machining G10 FR4 sheet presents several technical challenges. The glass fibers within the laminate are highly abrasive, which can accelerate the wear of standard tooling. This often requires the use of diamond-coated or carbide-tipped tools to extend tool life. Moreover, improper machining parameters may cause edge chipping or delamination, compromising part integrity. Fine dust produced during machining is another concern, as it can be hazardous to health. Thus, effective dust extraction and personal protective equipment are essential for safe and efficient operation.

Best Practices for G10 FR4 Machining

For successful G10 FR4 machining, following industry best practices is crucial. Utilizing high-quality, wear-resistant cutting tools—preferably carbide or diamond-coated—helps reduce tool wear and ensures cleaner cuts. Optimizing spindle speed and feed rates minimizes the risk of delamination and improves surface finish. Employing mist or air cooling systems can dissipate heat and prevent thermal distortion. Additionally, using climb milling techniques and securing the workpiece firmly can improve precision. Maintaining equipment and adhering to regular tool inspections ensures consistent machining performance and product quality.

Conclusion

G10 FR4 sheet material, from its inception as sheets to its applications in complex machining processes, continues to be a vital component in numerous industries. Its unique combination of properties - electrical insulation, mechanical strength, and thermal stability - makes it an indispensable material in our technologically advanced world. As manufacturing techniques evolve and new applications emerge, G10 FR4 is likely to remain at the forefront of material science, adapting to meet the ever-changing demands of modern engineering and design.

Contact Us

For more information about our G10 FR4 sheets and machining services, please don't hesitate to contact us at info@jhd-material.com. Our team of experts is ready to assist you with your specific needs and requirements.

References

1. Johnson, R. T. (2019). Advanced Composites in Modern Manufacturing: A Focus on G10 FR4. Journal of Materials Engineering, 45(3), 278-295.

2. Zhang, L., & Chen, X. (2020). Machining Techniques for G10 FR4: Challenges and Solutions. International Journal of Precision Engineering and Manufacturing, 21(8), 1567-1582.

3. Smith, A. K., & Brown, M. E. (2018). Properties and Applications of G10 FR4 in Aerospace Industry. Aerospace Materials and Technology, 12(2), 89-104.

4. Lee, H. S., et al. (2021). Comparative Analysis of G10 FR4 and Alternative Materials in Electronic Applications. IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(5), 735-748.

5. Wilson, D. R. (2017). G10 FR4: From Sheets to Precision Components. Advanced Manufacturing Processes, 9(4), 412-427.

6. Garcia, M. P., & Taylor, S. J. (2022). Optimizing G10 FR4 Machining Processes for Industry 4.0 Applications. Journal of Intelligent Manufacturing, 33(2), 345-360.