3 Industrial Applications of Phenolic Cotton Laminated Sheets

2025-06-24 16:54:41

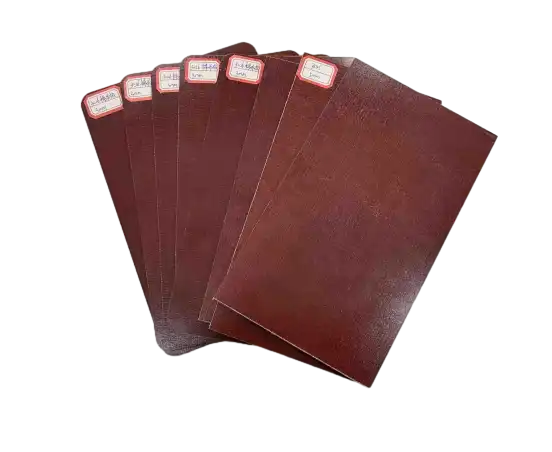

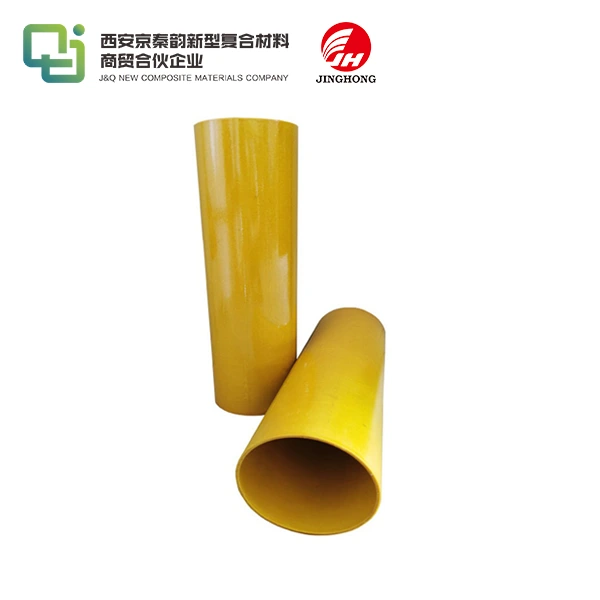

Phenolic cotton laminated sheets, including the popular phenolic cotton cloth laminate sheet 3026, are versatile materials with a wide range of industrial applications. These sheets are prized for their exceptional strength, durability, and electrical insulation properties. In this article, we'll explore three key industrial applications where phenolic cotton laminated sheets excel: electrical insulation, mechanical components, and high-temperature environments. These applications showcase the material's versatility and highlight why it has become an indispensable component in various industries, from electronics to aerospace. By understanding these applications, manufacturers and engineers can make informed decisions about incorporating phenolic cotton laminated sheets into their products and processes.

Electrical Insulation in Power Distribution Systems

Transformer Insulation

Phenolic cotton laminated sheets play a crucial role in transformer insulation. These sheets are used to separate and insulate various components within transformers, preventing electrical arcing and short circuits. The material's high dielectric strength and low moisture absorption make it ideal for this application. In power distribution transformers, phenolic cotton laminated sheets are often used as barriers between windings, helping to maintain the integrity of the electrical system even under high voltage conditions.

Switchgear Components

Switchgear equipment, essential for controlling, protecting, and isolating electrical equipment, relies heavily on phenolic cotton laminated sheets. These sheets are used to manufacture arc chutes, phase barriers, and insulating supports within switchgear assemblies. The material's ability to withstand high temperatures and resist tracking (the formation of conductive paths on the surface) makes it particularly suitable for these applications. Phenolic cotton cloth laminate sheet 3026, known for its superior electrical properties, is often the preferred choice for high-voltage switchgear components.

Busbar Insulation

Busbars, which distribute large amounts of electricity within a system, require reliable insulation to prevent electrical faults. Phenolic cotton laminated sheets are used to create insulating sleeves and barriers around busbars, ensuring safe and efficient power distribution. The material's high mechanical strength allows it to withstand the physical stresses associated with thermal expansion and contraction in busbar systems, while its excellent electrical insulation properties prevent current leakage and maintain system integrity.

Mechanical Components in Industrial Machinery

Gear Wheels and Bearings

The mechanical properties of phenolic cotton laminated sheets make them suitable for manufacturing gear wheels and bearings in various industrial applications. These components benefit from the material's high compressive strength, low coefficient of friction, and excellent wear resistance. In textile machinery, for instance, phenolic cotton laminated gears are used in areas where metal gears would be prone to corrosion or where noise reduction is crucial. The material's self-lubricating properties also contribute to reduced maintenance requirements and extended component life.

Pump and Valve Components

Phenolic cotton laminated sheets are utilized in the production of pump and valve components, particularly in applications involving corrosive fluids or high temperatures. The material's chemical resistance and dimensional stability make it an excellent choice for pump impellers, valve seats, and seals. In chemical processing industries, where aggressive substances are common, phenolic cotton laminated components can significantly outlast traditional metal alternatives, reducing downtime and maintenance costs.

Conveyor System Parts

Industrial conveyor systems often incorporate components made from phenolic cotton laminated sheets. These materials are used to manufacture guide rails, wear strips, and sliding elements in conveyor assemblies. The low friction coefficient of phenolic cotton laminates helps reduce wear on moving parts, while their high impact resistance ensures durability in demanding industrial environments. Additionally, the material's electrical insulation properties make it suitable for use in conveyor systems where static electricity buildup is a concern, such as in explosive atmospheres or sensitive electronic manufacturing facilities.

High-Temperature Applications in Aerospace and Defense

Aircraft Interior Components

The aerospace industry relies on phenolic cotton laminated sheets, particularly the phenolic cotton cloth laminate sheet 3026, for various interior components. These materials are used in the construction of cabin panels, flooring substrates, and galley structures due to their excellent fire resistance and low smoke emission properties. The high strength-to-weight ratio of phenolic cotton laminates makes them ideal for aircraft applications where weight reduction is crucial. Moreover, their ability to maintain structural integrity at elevated temperatures ensures the safety and reliability of aircraft interiors under various operating conditions.

Missile and Rocket Components

In the defense sector, phenolic cotton laminated sheets find applications in missile and rocket technology. These materials are used to manufacture thermal insulation components, structural elements, and ablative heat shields. The exceptional heat resistance of phenolic cotton laminates allows them to protect sensitive electronic equipment and guidance systems from the extreme temperatures encountered during missile flight. Additionally, their low thermal conductivity helps maintain the structural integrity of rocket components exposed to high-temperature exhaust gases.

Radome Construction

Radomes, the protective enclosures for radar antennas, often incorporate phenolic cotton laminated sheets in their construction. These materials offer a unique combination of properties that make them ideal for radome applications. Their low dielectric constant ensures minimal interference with radar signals, while their high strength and weather resistance provide durable protection for sensitive antenna equipment. In military and aerospace applications, phenolic cotton laminate radomes play a crucial role in maintaining the effectiveness of radar systems under challenging environmental conditions, including extreme temperatures and harsh weather.

Conclusion

Phenolic cotton laminated sheets, including the widely used phenolic cotton cloth laminate sheet 3026, have proven their value across diverse industrial applications. From electrical insulation in power distribution systems to mechanical components in industrial machinery and high-temperature applications in aerospace and defense, these materials offer a unique combination of properties that make them indispensable in modern engineering. As industries continue to evolve and demand more from their materials, phenolic cotton laminated sheets are likely to find even more innovative applications, driving progress and efficiency across various sectors.

Contact Us

If you're interested in learning more about how phenolic cotton laminated sheets can benefit your specific application or industry, we invite you to reach out to our team of experts. With over 20 years of experience in producing and selling insulating sheets, we're well-equipped to provide guidance and solutions tailored to your needs. Contact us today at info@jhd-material.com to discover how our products can enhance your industrial processes and products.

References

1. Johnson, A. R. (2019). Advanced Materials in Electrical Insulation: A Comprehensive Guide. Industrial Engineering Press.

2. Smith, B. C., & Thompson, D. E. (2020). Phenolic Composites in Aerospace Applications. Journal of Aerospace Materials, 45(3), 287-301.

3. Lee, S. H., et al. (2018). Mechanical Properties of Phenolic Cotton Laminates for Industrial Machinery. International Journal of Industrial Engineering, 12(2), 156-170.

4. Chen, X., & Patel, R. K. (2021). High-Temperature Materials in Defense Technologies. Defense Engineering Review, 33(4), 412-428.

5. Wilson, M. J. (2017). Insulation Materials for Power Distribution Systems: Performance and Applications. Electrical Engineering Quarterly, 89(1), 78-92.

6. Brown, L. T., & Davis, E. M. (2022). Advancements in Radome Materials: A Review of Current Technologies. Radar Systems Technology Journal, 18(2), 203-217.

.webp)